Binding board thick frame printing process

A thick frame and process technology, used in printed circuits, printed circuit manufacturing, printed circuit drying, etc., can solve the problems of difficult control, product defects, and high production costs, and achieve easy control, high product reliability, and side erosion. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

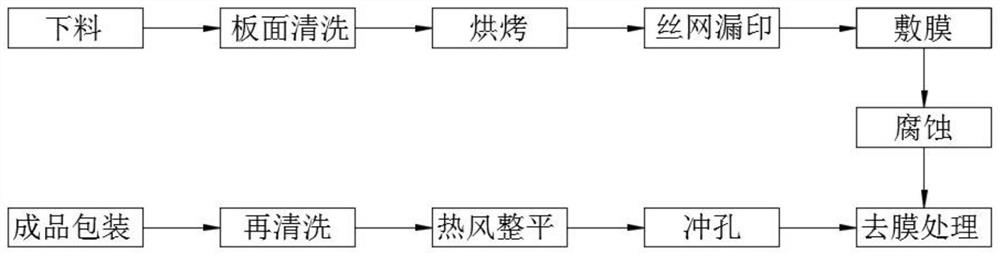

[0029] The invention provides a thick frame printing process for a binding plate, comprising the following steps:

[0030] Step S1: blanking, cutting the substrate into the desired shape to make a binding board;

[0031] Step S2: Clean the surface of the board, put the binding board into water, and use ultrasonic cleaning to clean the surface to remove surface residues;

[0032] Step S3: Bake, bake the cleaned binding board in a nitrogen-filled oven at a temperature of 155°C for 40 minutes, and dry it with water to avoid explosion and shrinkage;

[0033] Step S4: screen printing, print the required circuit diagram on the binding board through screen printing lead-free solder paste, use lead-free solder with a composition of 96.5Sn / 3.5Ag, which has the characteristics of high strength and high melting point , the viscosity is controlled at 770,000 CPS, and screen printing is performed at room temperature;

[0034] Step S5: apply a film, apply a protective film of the circuit ...

Embodiment 2

[0042] The invention provides a thick frame printing process for a binding plate, comprising the following steps:

[0043] Step S1: blanking, cutting the substrate into the desired shape to make a binding board;

[0044] Step S2: Clean the surface of the board, put the binding board into water, and clean it by ultrasonic cleaning;

[0045] Step S3: Bake, bake the cleaned binding board in a nitrogen-filled oven at a temperature of 145°C for 40 minutes, and dry it with water;

[0046] Step S4: screen printing, print the required circuit diagram on the binding board through screen printing lead-free solder paste, use lead-free solder with a composition of 95.5Sn / 3.5 / Ag / 1Zn, and control the viscosity at 770,000 CPS, screen printing at room temperature;

[0047] Step S5: apply a film, apply a protective film of the circuit diagram on the binding board, and prepare for corrosion;

[0048] Step S6: Corrosion, spraying the etching solution into a spray on the previously processed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com