Surface light source, its preparation method and display device using the surface light source

A surface light source, fluorescent film technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of surface light source return light efficiency loss and other problems, improve reflectivity and overall light efficiency, high excitation energy, and facilitate control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

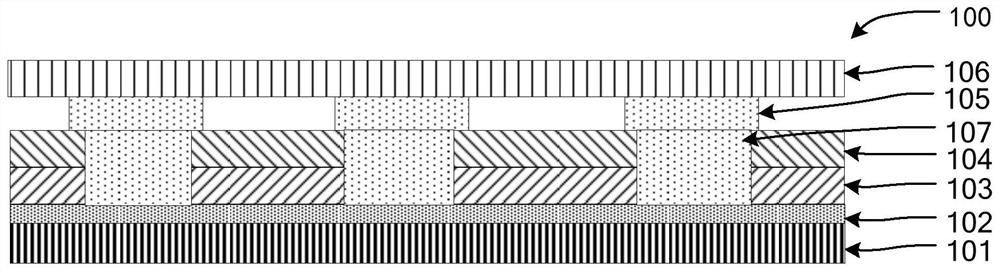

[0036] Such as figure 1 As shown, in one embodiment, the surface light source 100 of the present invention includes a substrate 101 , a wire layer 102 , a specular reflection layer 103 , a high temperature resistant film layer 104 , several LED chips 105 , and a fluorescent film 106 .

[0037] The substrate 101 may be an FPC substrate or a PCB substrate. In this embodiment, the substrate 101 is an FPC flexible substrate.

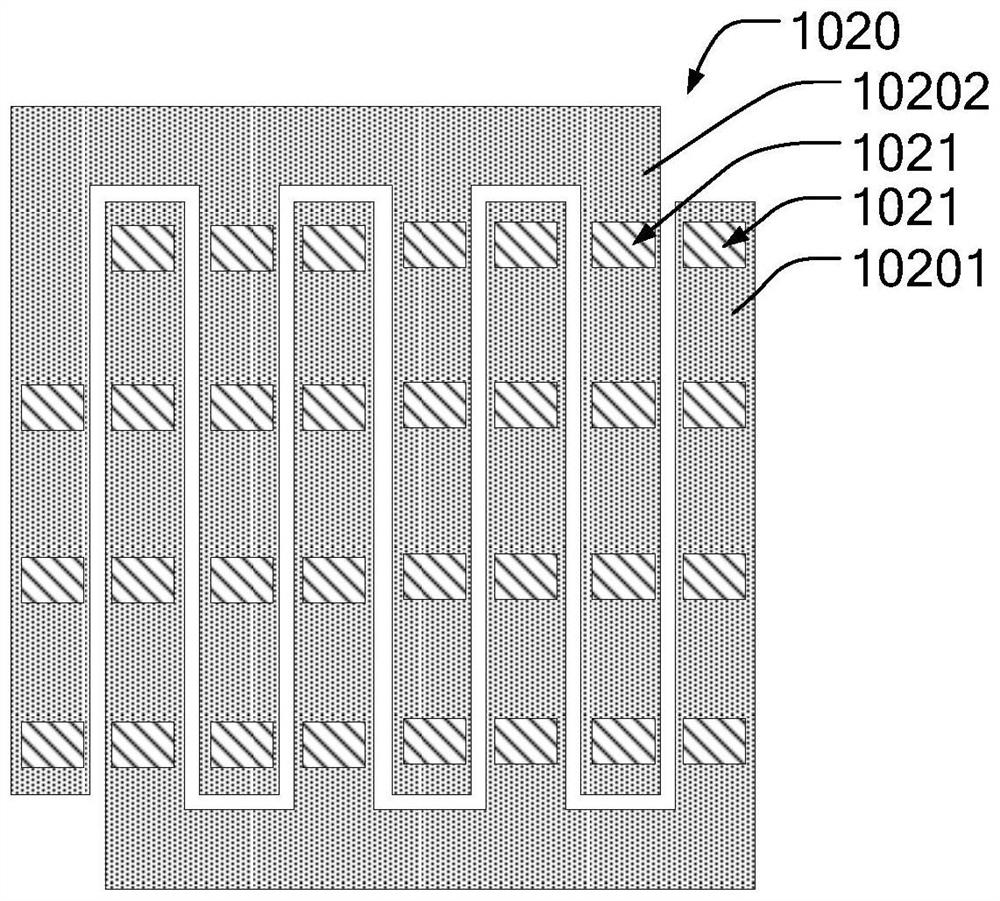

[0038] The wire layer 102 has several wires 1020 (see fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com