Circuit board detection method

A detection method and circuit board technology, which is applied in the detection field, can solve the problems of circuit board deformation, film expansion and shrinkage improvement, and circuit board size is not exactly the same, so as to improve the service life and avoid the effect of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] see Figure 1 to Figure 6 , is Embodiment 1 of the present invention. What needs to be explained first is that this embodiment corresponds to the relevant quantities and shapes mentioned in the drawings, and is only used to specifically illustrate the implementation of the present invention, so as to facilitate the understanding of the content of the present invention. , not to limit the protection scope of the present invention.

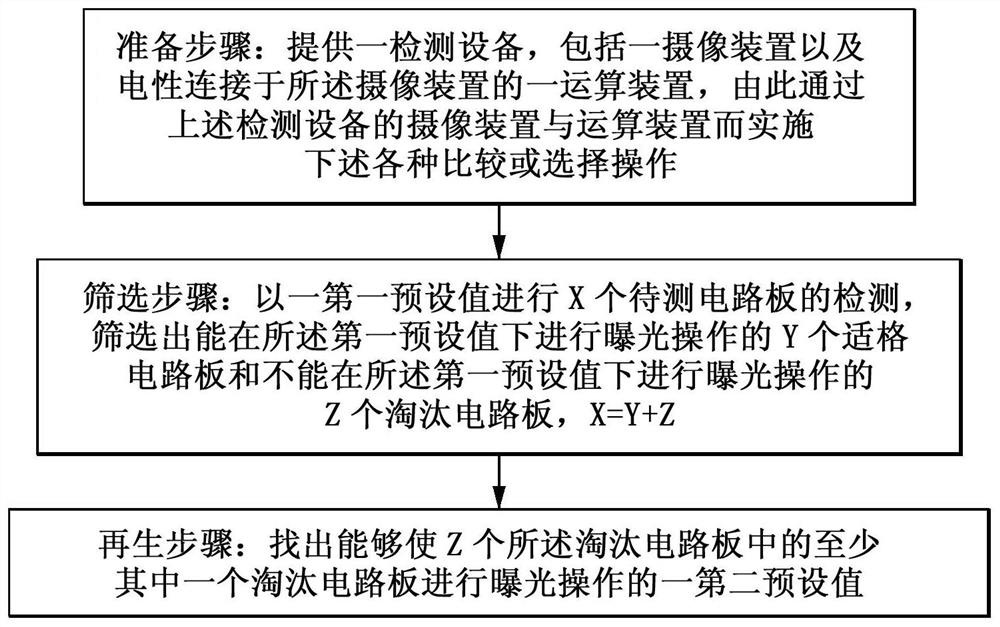

[0028] like figure 1 As shown, this embodiment discloses a circuit board inspection method, especially a circuit board inspection method before exposure operation. The circuit board inspection method includes the following steps: a preparation step, a screening step, a regeneration step, and an exposure step. The specific implementation of each step will be described below, but the following description does not limit the necessary implementation sequence of each step.

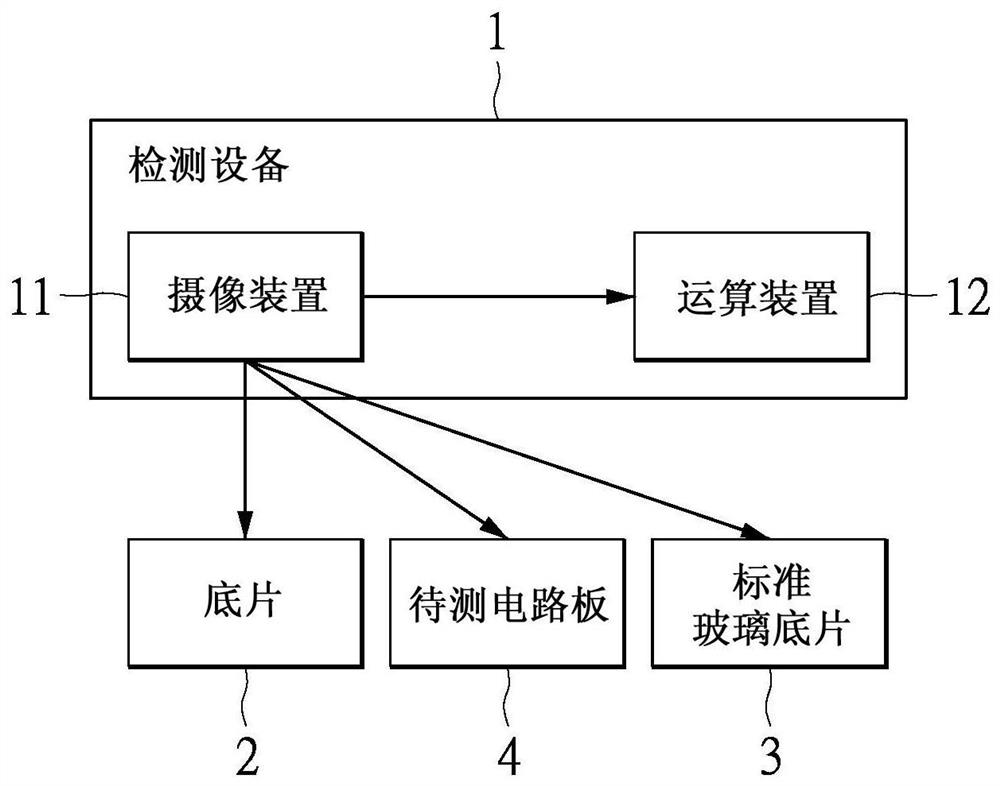

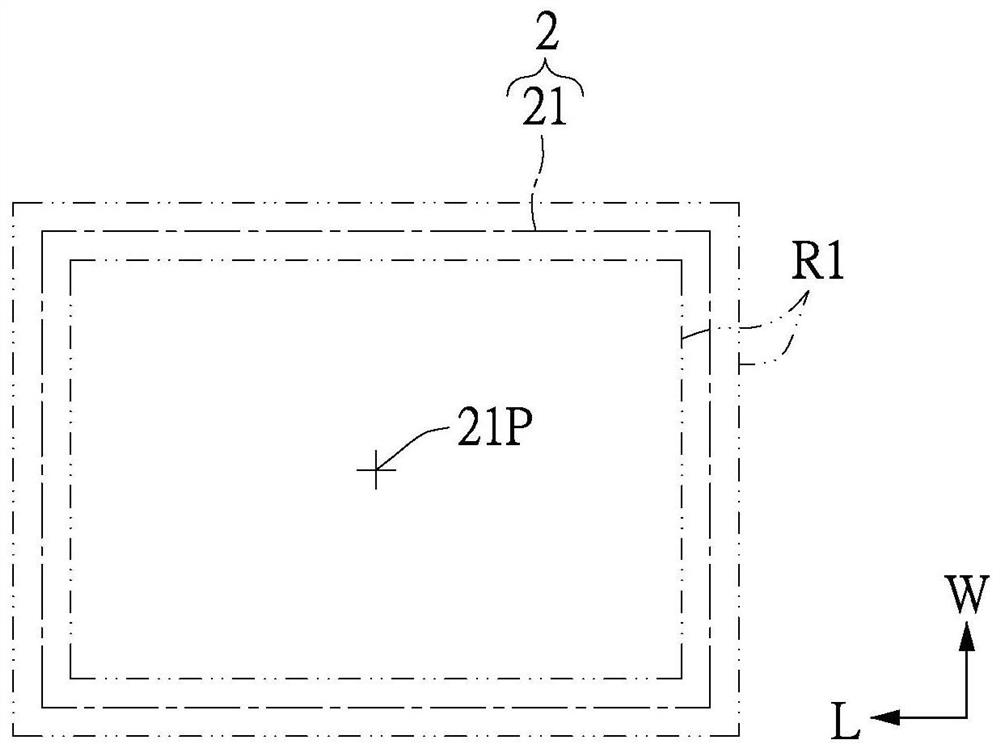

[0029] Preparation steps: see figure 2 and image 3 As shown, a de...

Embodiment 2

[0040] see Figure 7 , which is Embodiment 2 of the present invention. This embodiment is similar to Embodiment 1 above, and the same parts will not be described again. The main differences between the two embodiments are as follows.

[0041] Specifically, this embodiment discloses a circuit board exposure method, including the circuit board detection method described in Embodiment 1 and an exposure step. Wherein, the exposing step is: according to the first preset value R1, sequentially exposing the Y qualified circuit boards 41, and exposing at least one of the corresponding circuit boards 41 according to the second preset value R2. The exposing operation is performed on the elimination circuit board 42 described above.

[0042] Furthermore, according to the above-mentioned M kinds of preset values, the corresponding elimination circuit boards 42 are respectively subjected to an exposure operation. It should be noted that if the number of eliminated circuit boards 42 corre...

Embodiment 3

[0044] see Figure 8 and Figure 9 , is Embodiment 3 of the present invention. This embodiment is similar to the above-mentioned Embodiment 2, and the similarities will not be described again. The main differences between this embodiment and the above-mentioned two embodiments are as follows.

[0045] Specifically, this embodiment discloses a circuit board inspection method, which includes a preparation step, a screening step, a regeneration step, and an exposure step, so the circuit board inspection method in this embodiment can also be called a circuit board inspection method. method (or circuit board exposure method). Among them, the above-mentioned preparation steps, screening steps, regeneration steps, and exposure steps have been described in the first and second embodiments and will not be repeated in this embodiment, and this embodiment will further explain how to improve the exposure steps in the following .

[0046] Further, the exposure step is implemented in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com