Positive electrode material and preparation method thereof, lithium ion battery positive electrode and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, and electrode manufacturing. It can solve the problems of electrolyte reaction and insufficient density of the coating layer, and achieve the reduction of residual alkali, inhibition of structural phase transition and unit cell The effect of expansion and contraction and shortening of the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

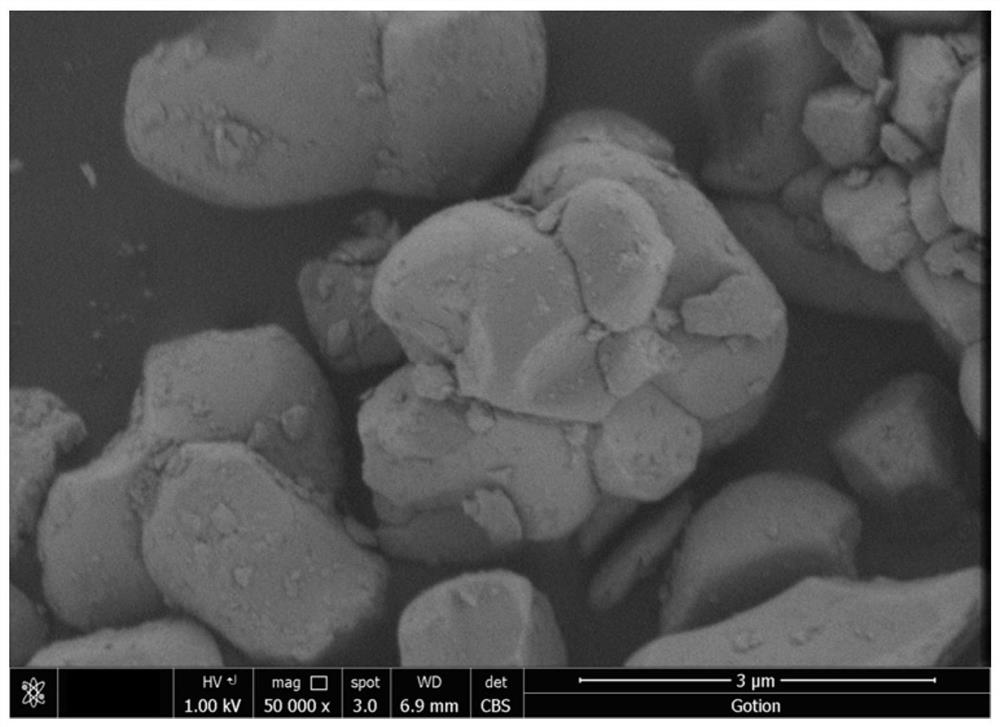

Image

Examples

preparation example Construction

[0037] A second aspect of the invention provides a method of preparing a positive electrode material as described in the first aspect of the invention, comprising the steps of:

[0038] After mixing nickel cobalt manganese precursors, Zr dopants, and lithium sources in accordance with the chemical metering, the first sintering is performed, and the Zr doped matrix material is performed;

[0039] Base material to the Zr doped 3 BO 3 And Al 2 O 3 After mixing well, the second sintering was performed, and Zr doped B / Al co-coated dual-altered nickel-cobalt-oxanate lithium single crystal positive electrode material was obtained.

[0040] Further, the first sintering process is specifically: after 440-500 ° C for 5-8 hours, it is raised to 900-950 ° C, and the insulation is 15-18 h; in one or more embodiments of the present invention, The heating rate is constant, preferably, the temperature rise rate is 5 ° C / min, and the first sintering is carried out in an atmosphere filled with ...

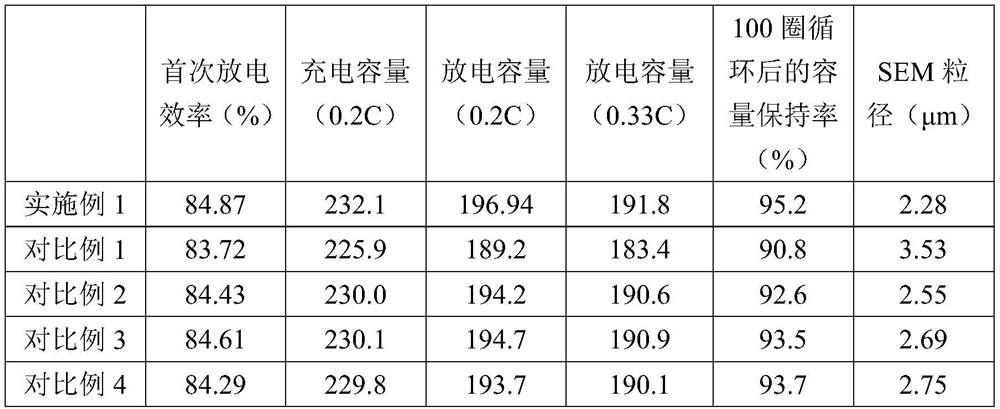

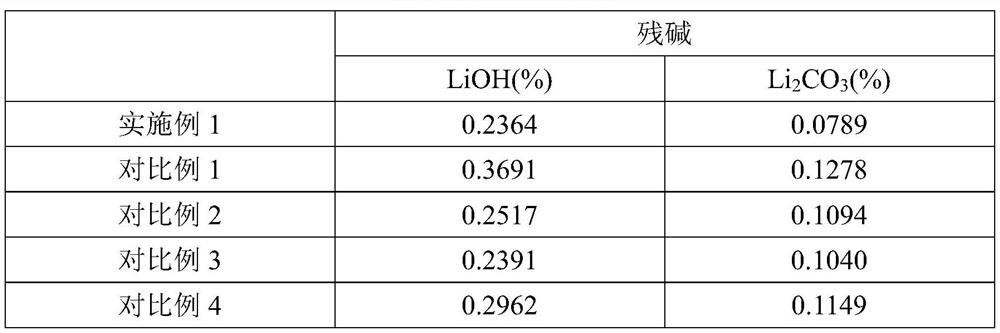

Embodiment 1

[0046] Preparation of Zr doped matrix materials

[0047] 100g Ni 0.75 CO 0.125 Mn 0.125 (OH) 2 Precursor, 0.1% doped amount of Zro 2 And lithium hydroxide is added to the high-speed mixing machine, which is mixed well, wherein the lithium hydroxide and nickel-cobalt manganese precursors are added in accordance with molar ratio li: me = 1.05: 1; the mixed uniform material is placed in an oxygen atmosphere of 99.9%. The first sintering was performed, first warmed up to 480 ° C for 5 hours at a speed of 5 ° C / min, then continued to heat up at 5 ° C / min to heat the temperature for 15 h, naturally cooling and cooling, pulverized, over 300 mesh sieve, obtained Zr doped matrix material.

[0048] Preparation of modified nickel cobalt manganese three yuan single crystal positive electrode material

[0049] It is called H. 3 BO 3 Alone 2 O 3 After mixing is uniform, the second sintering is carried out under the oxygen atmosphere, and the temperature is warmed to 400 ° C for 6 h under ...

Embodiment 2

[0069] Preparation of Zr doped matrix materials

[0070] 100g Ni 0.75 CO 0.125 Mn 0.125 (OH) 2 Precursor, 0.15% doped amounts of zirconium hydroxide and lithium nitrate to add a high-speed mixing machine, wherein the lithium hydroxide and nickel-cobalt precursor are added in accordance with molar ratio Li: ME = 1.02: 1; The uniform material was placed under the conditions of the oxygen atmosphere of 99.9% for the first sintering, first warmed up to 440 ° C at a speed of 5 ° C / min, then continued to heat up at 5 ° C / min to heat the temperature for 16 h, natural Cooling cooling, pulverizing, over 300 mesh sieve, and obtaining a Zr doped matrix material.

[0071] Preparation of modified nickel cobalt manganese three yuan single crystal positive electrode material

[0072] It is called H with a 100 g of Zr doped matrix material and coating amount of 0.5 ‰ 3 BO 3 Alone 2 O 3 After mixing is uniform, the second sintering is carried out under the oxygen atmosphere, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com