Electric hoist

An electric hoist and electric motor technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of affecting the lifting safety, reducing the rope life of the electric hoist, and the vibration of the electric hoist, so as to avoid the expansion and retraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

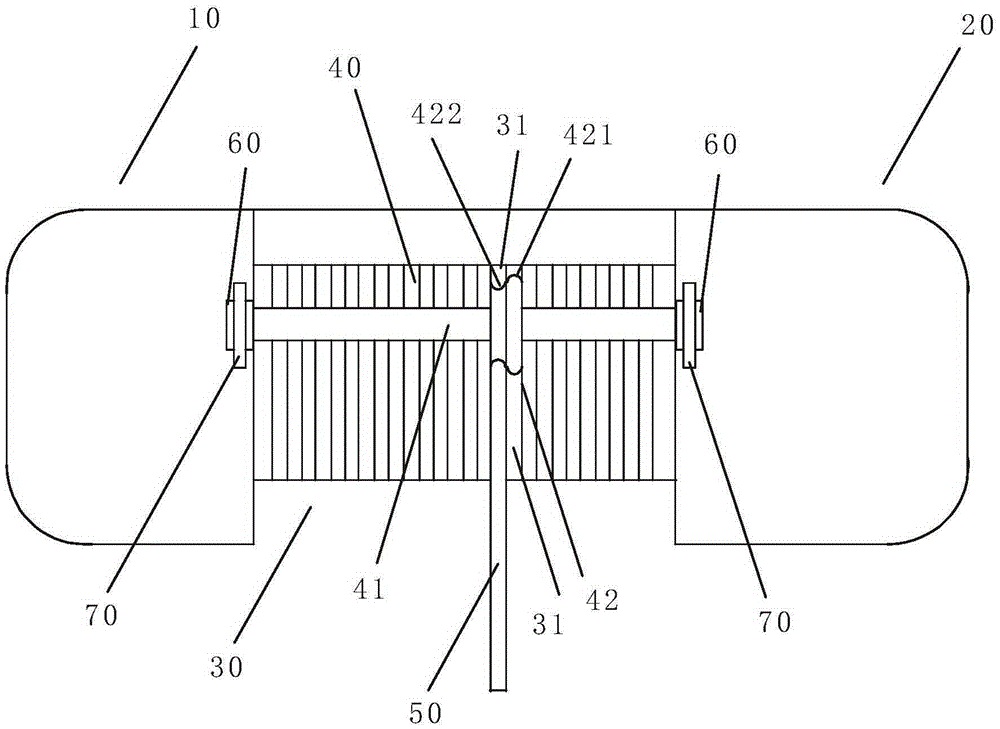

[0013] Next, an electric hoist as an example of the present invention will be described based on the drawings.

[0014] figure 1 It is a schematic front view showing the electric hoist of the present invention.

[0015] Such as figure 1 As shown, the electric hoist of the present invention includes a reducer 10 on one side, a lifting motor 20 on the other side, and a reel 30 located between the reducer 10 and the lifting motor 20 .

[0016] A rope guide 40 straddling the reel 20 is erected on the housing of the speed reducer 10 and the housing of the lifting motor 20 . The rope guide 40 includes a connecting shaft 41 and a guiding disc 42 slidingly connected with the connecting shaft 41 .

[0017] The two ends of the connecting shaft 41 are respectively connected with the housing of the speed reducer 10 and the housing of the lifting motor 20, and the middle part of the guide rope disc 42 has a through connection hole for sliding connection with the connecting shaft 41, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com