Circuit board buried hole resin hole plugging method

A resin plug hole, circuit board technology, applied in printed circuit, multilayer circuit manufacturing, printed circuit manufacturing and other directions, can solve production problems, thin plate grinding plate expansion and shrinkage, serious problems, achieve good reliability, solve the problem of cracked board , to avoid the effect of expansion and contraction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

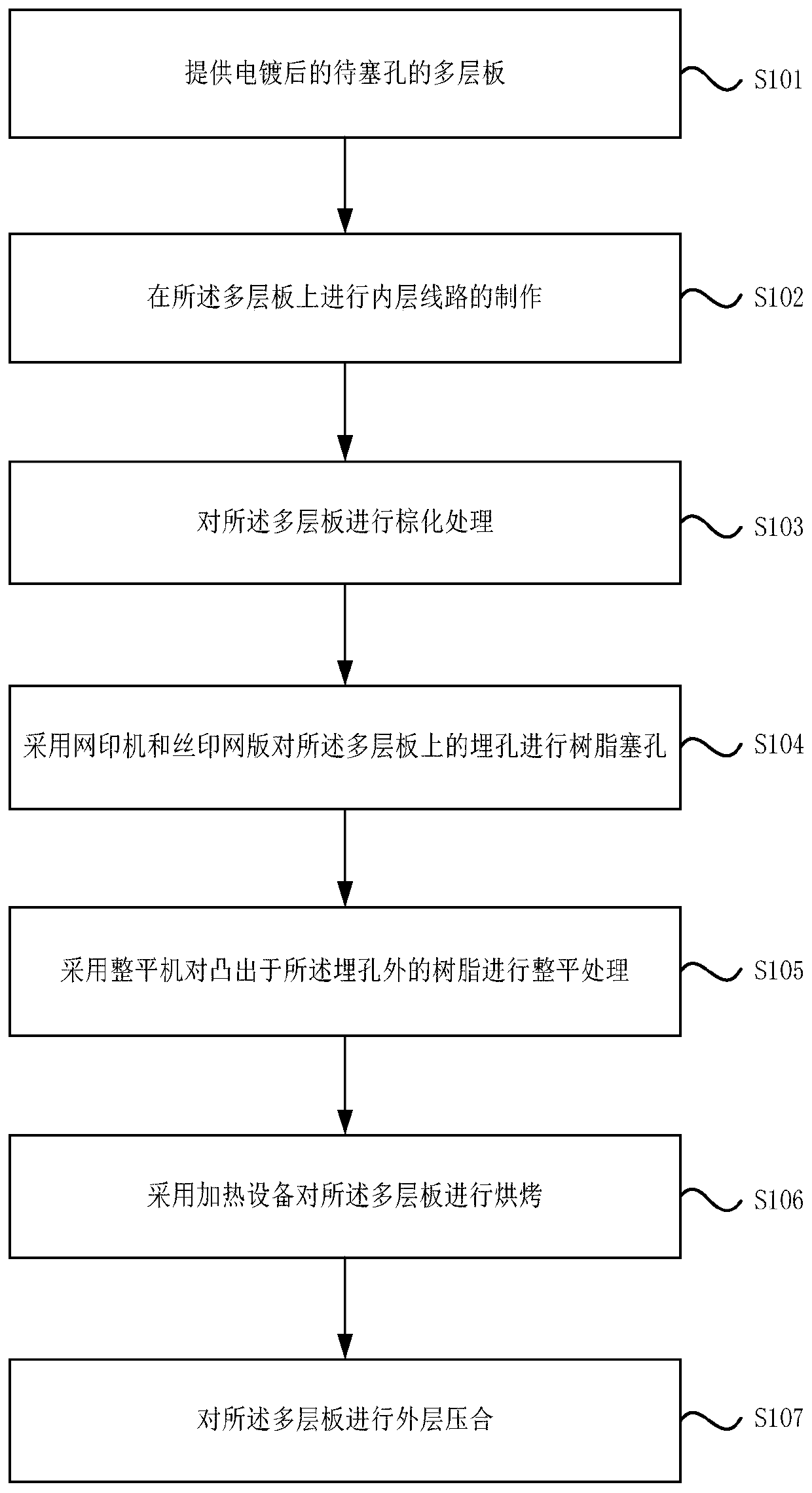

[0039] Please refer to the attached figure 1 , is a schematic flow chart of a method for resin plugging buried holes in circuit boards provided by Embodiment 1 of the present invention. This method is applicable to the scene of performing resin plugging on buried holes of HDI boards whose board thickness is getting thinner and thinner. The method specifically includes the following steps:

[0040] S101, providing a multi-layer board with holes to be plugged after electroplating;

[0041] Specifically, before the step S101, the method further includes:

[0042] (1) Pressing the prepared inner layer core board and the prepreg to obtain a multi-layer board;

[0043] (2) drilling the multi-layer board to form buried holes;

[0044] (3) Perform electroplating treatment on the multi-layer board.

[0045] S102. Fabricate inner-layer circuits on the multi-layer board;

[0046] S103, performing browning treatment on the multi-layer board;

[0047] It should be noted that the purp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com