Negative electrode active material for electrical equipment and electrical equipment using same

A technology of negative electrode active material and positive electrode active material, which is applied in the direction of active material electrode, non-aqueous electrolyte battery, negative electrode, etc., can solve the problems of reduced electrode cycle life, large expansion and contraction of negative electrode, and inability to obtain charge and discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

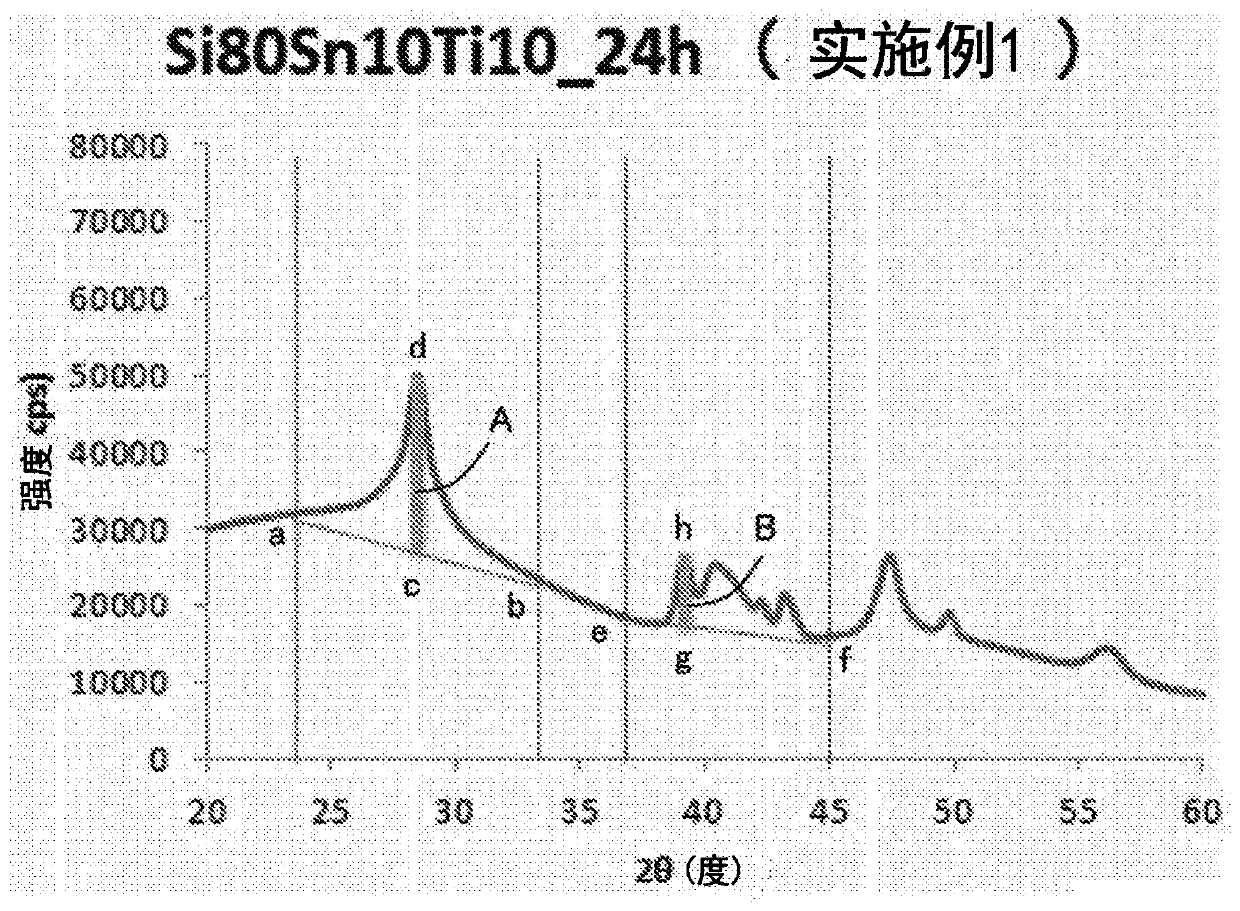

[0168] [Manufacture of silicon-containing alloy]

[0169] Fabrication of silicon-containing alloys (Si 80 sn 10 Ti 10) (the unit is mass%, the same below). Specifically, using a planetary ball mill device P-6 manufactured by Fritschd Company in Germany, zirconia grinding balls and alloy raw material powder were put into a zirconia grinding pot, and alloyed (alloying treatment) at 600 rpm for 24 hours. ), followed by pulverization at 400 rpm for 1 hour. It should be noted that the average particle diameter of the obtained silicon-containing alloy (negative electrode active material) powder was 0.3 μm.

[0170] [Production of Negative Electrode]

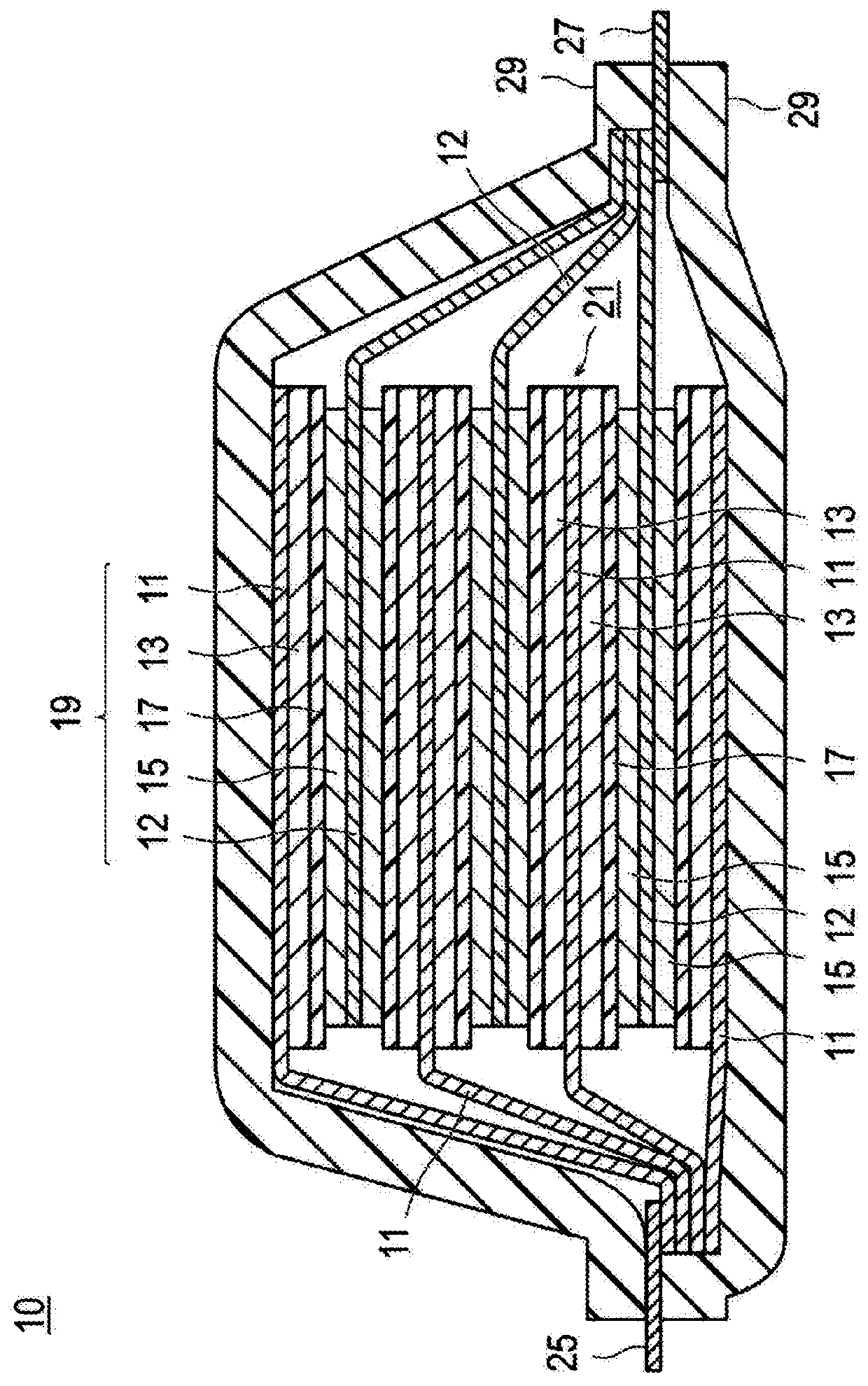

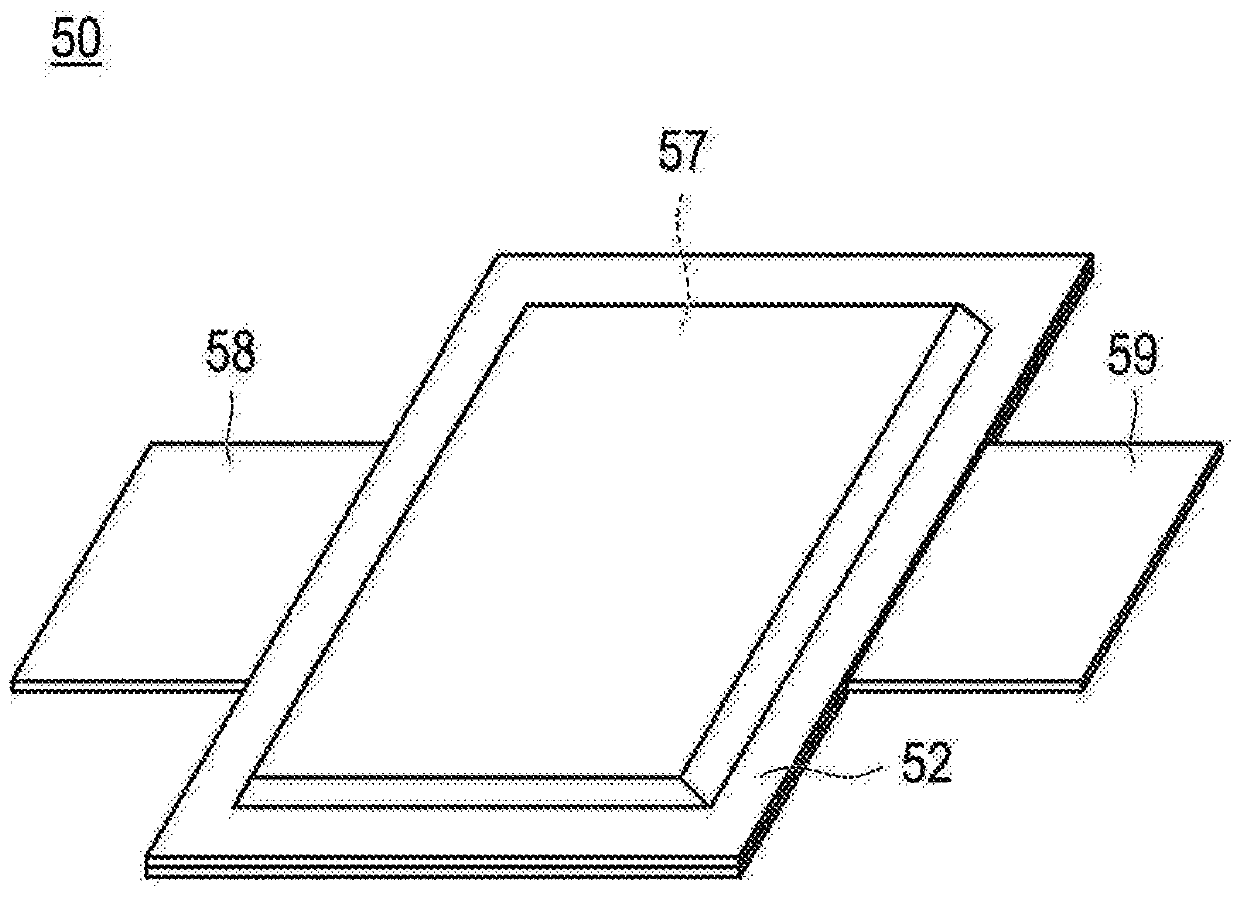

[0171] The above-produced silicon-containing alloy (Si 80 sn 10 Ti 10 ) 80 parts by mass, 5 parts by mass of acetylene black as a conductive additive, and 15 parts by mass of polyamideimide as a binder were mixed and dispersed in N-methylpyrrolidone to obtain a negative electrode slurry. Next, the obtained negative electrode s...

Embodiment 2

[0176] Change the composition of silicon-containing alloys to Si 70 sn 15 Ti 15 , except that, a negative electrode active material, a negative electrode, and a lithium ion secondary battery (coin battery) were produced in the same manner as in Example 1 above. It should be noted that the average particle diameter of the obtained silicon-containing alloy (negative electrode active material) powder was 0.3 μm.

Embodiment 3

[0178] Change the composition of silicon-containing alloys to Si 59 sn 22 Ti 19 , Change the time of alloying treatment when making silicon-containing alloy to 25 hours, except that, utilize the same method as above-mentioned Example 1, make negative electrode active material, negative electrode and lithium ion secondary battery (coin battery). It should be noted that the average particle diameter of the obtained silicon-containing alloy (negative electrode active material) powder was 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com