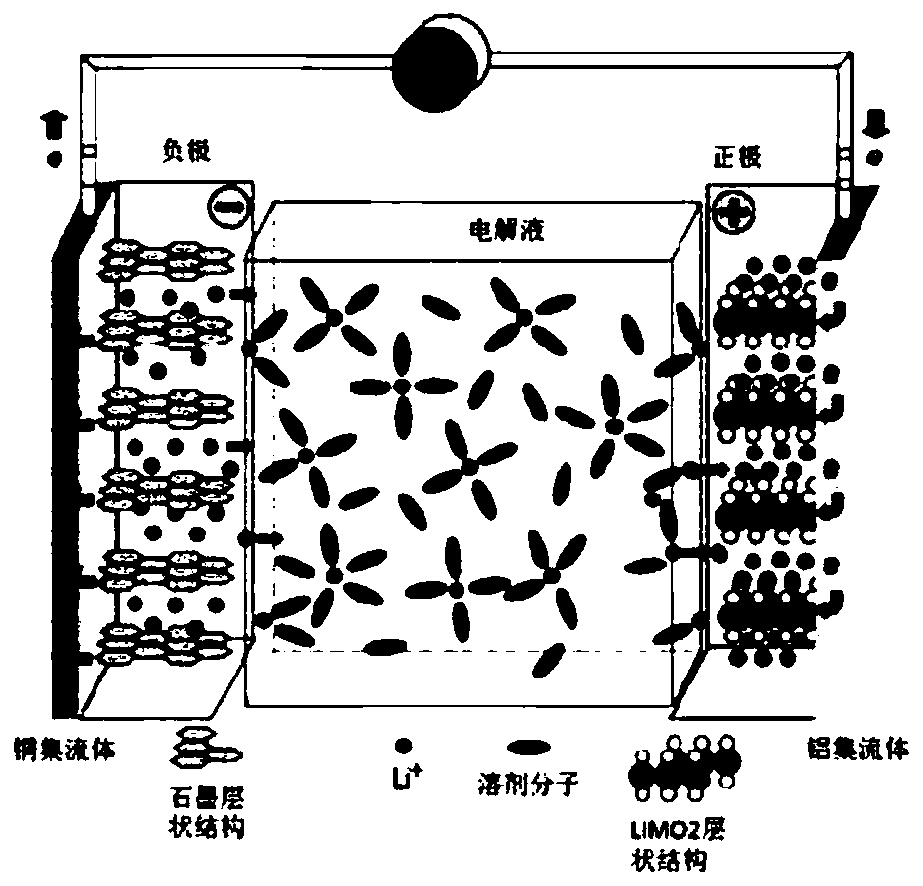

Lithium ion battery positive electrode material and preparation method

A technology for lithium-ion batteries and positive electrode materials, applied in the field of materials, can solve the problems of increased impedance of positive electrode materials, collapse of layered structure, crystal cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

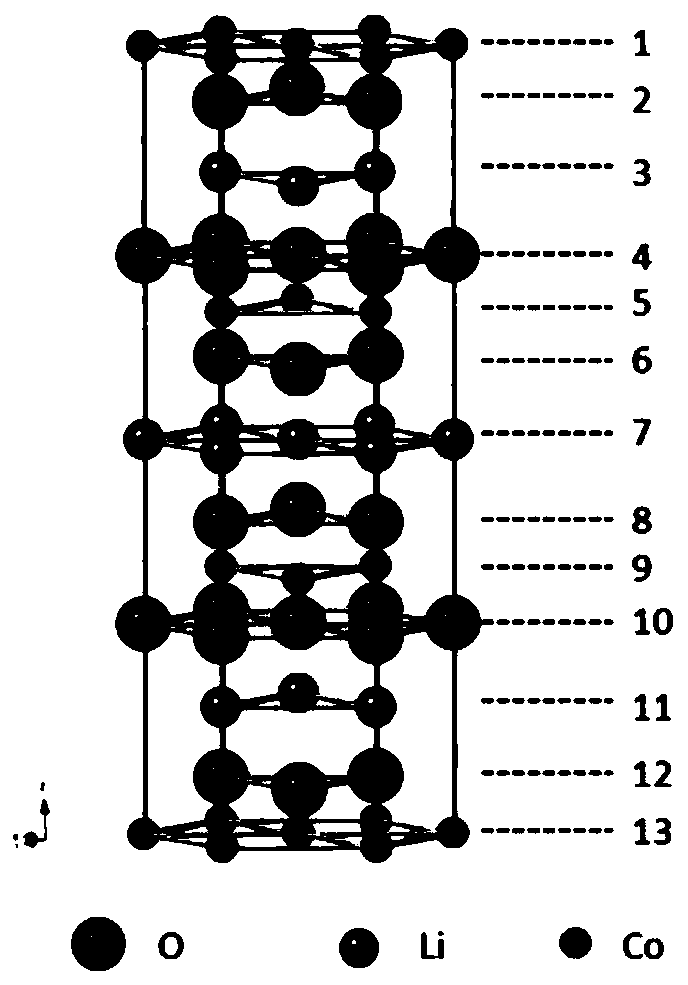

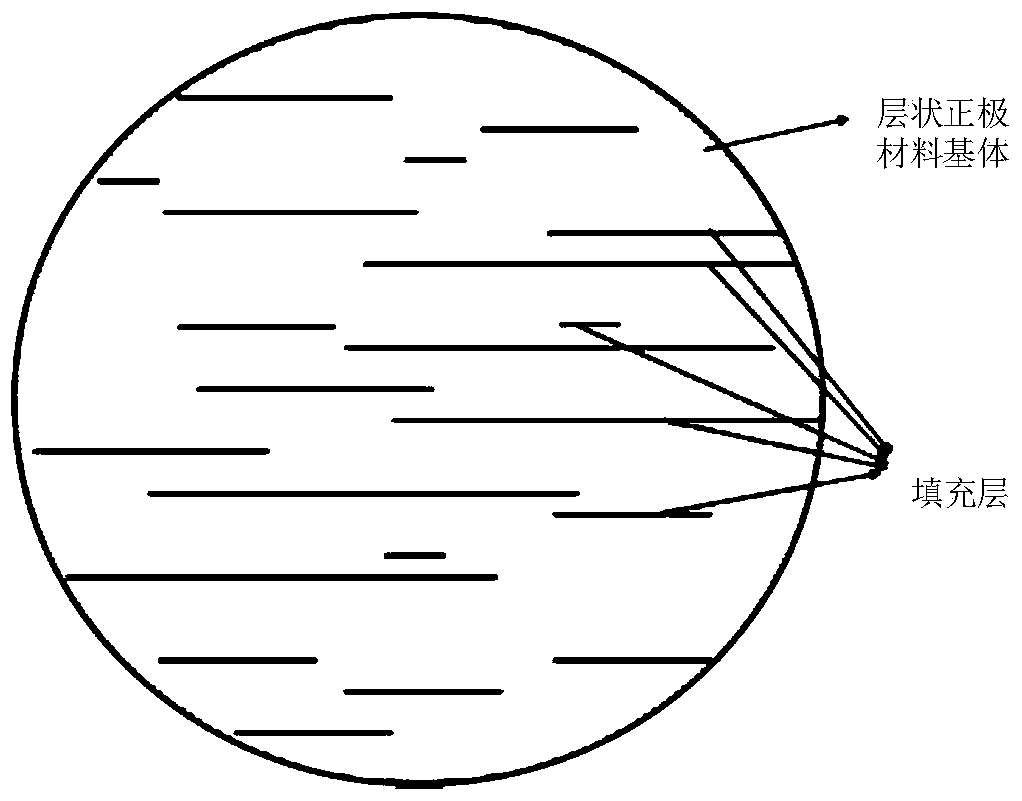

[0082] A lithium cobalt oxide positive electrode material with a filling layer, made of MgF 2 Constitute the filling layer, the matrix of the lithium cobalt oxide layered positive electrode material is LiCo 0.99 al 0.01o 2 , its preparation method comprises the following steps:

[0083] Co doped with 1% Al molar content 3 o 4 The precursor and lithium carbonate are mixed evenly in a molar ratio of Li:Co=1.05, placed in a muffle furnace at 1050°C, the sintering time is 12h, and the cooling rate is controlled at 10°C / min. After cooling to room temperature, the sintered product is pulverized , to obtain lithium cobalt oxide matrix material LiCo 0.99 Al 0.01 o 2 ;

[0084] Mix the lithium cobaltate base material and magnesium fluoride uniformly according to the molar ratio of 100:0.5, place it in a muffle furnace and sinter at 900°C for 6 hours, and then pulverize the sintered product to obtain cobaltate with a filled layer Lithium cathode material 0.05MgF 2 ·LiCo 0.99 ...

Embodiment 2

[0091] A high-nickel ternary cathode material with a filled layer, made of AlF 3 Constitute the filling layer, the matrix of the lithium cobalt oxide layered positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , its preparation method comprises the following steps:

[0092] Nickel sulfate, cobalt sulfate, manganese sulfate are uniformly mixed according to the molar ratio of Ni: Co: Mn=0.8: 0.1: 0.1 to obtain a mixed solution A of 1.0mol / L, and the concentration is taken by weighing 20% sodium hydroxide solution and removed Each 200g of deionized water was mixed uniformly to obtain 5mol / L mixed solution B; 100g concentrated ammonia water and 150g deionized water with a concentration of 20% were weighed and stirred uniformly to obtain 3.8mol / L mixed solution C. Weigh 300g, 400g, and 100g of the above mixed solution A, mixed solution B, and mixed solution C respectively, add 1300g of pure water to the reactor, and add mixed solution A, mixed solution B, and mixed solu...

Embodiment 3

[0097] A lithium-rich manganese-based positive electrode material with a filled layer consisting of TiO 2 Constitute the filling layer, and the matrix of the lithium-rich manganese-based layered positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , its preparation method comprises the following steps:

[0098] Nickel sulfate, cobalt sulfate, and manganese sulfate were uniformly mixed according to the molar ratio of Ni:Co:Mn=0.21:0.12:0.67, dissolved in deionized water to obtain a mixed solution with a total concentration of metal elements of 2mol / L, and the concentration was weighed as Slowly add 0.2mol / L sodium carbonate solution into the mixed solution, stirring while adding, control the reaction pH value = 11, the reaction temperature is 60°C, and the reaction time is 40h. After the reaction is completed, the slurry is suction filtered 1. After washing, dry at 120°C for 24 hours, and then sinter at 500°C for 5 hours in an air atmosphere to obtain a nickel-cobalt-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com