Thick copper plate for different types of circuit boards and production method for circuit board

A production method and technology of thick copper plate, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, circuit lamination, etc., can solve the problem that the expansion and shrinkage of copper plate and FR4 substrate is not easy to control, and it is impossible to arrange and combine multiple circuit boards. , increase production costs and other issues, to achieve the effect of reducing production process and production time, avoiding sheet material expansion and shrinkage, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

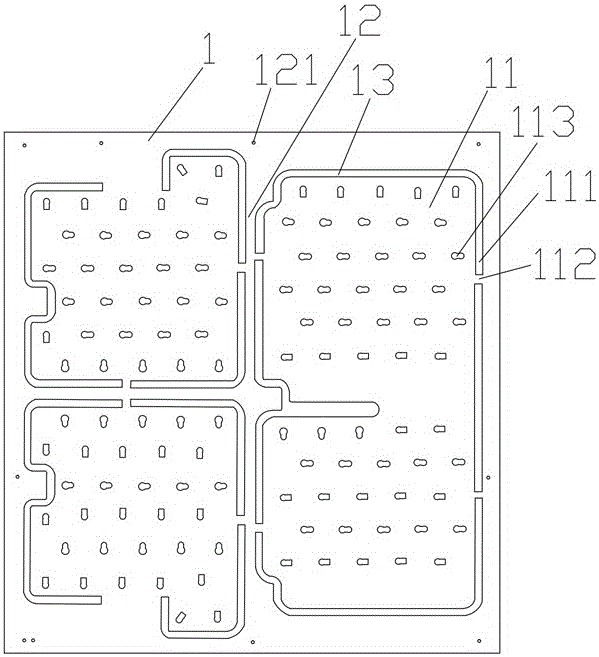

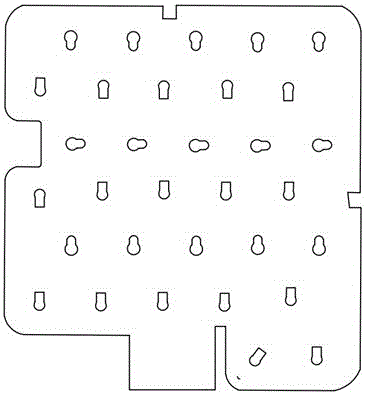

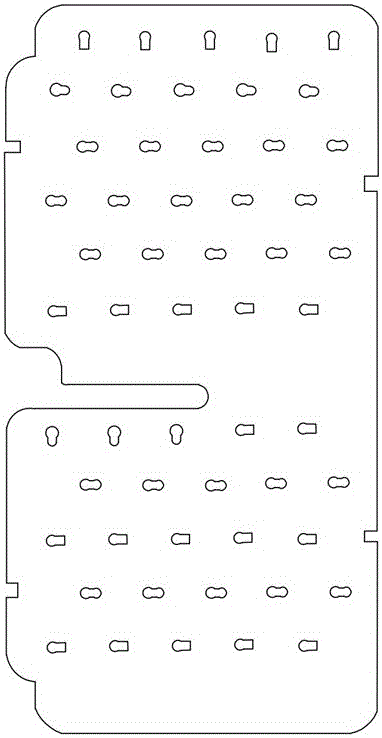

[0024] Such as figure 1 As shown, a thick copper plate of a different type of circuit board includes a thick copper plate 1 with a thickness of 1.0-1.2mm in a square structure. In order to improve the utilization rate of the thick copper plate and save production raw materials, the thick copper plate 1 is provided with a plurality of thick copper plate units 11 corresponding to different types of circuit boards and a connection area 12 connecting each thick copper plate unit, through the connection area 12 The connection makes each thick copper plate unit connected to the whole thick copper plate and has an integrated structure. The outer side of each thick copper plate unit 11 is provided with a rim 111 and a connecting position 112, and the gong edge 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com