A kind of multilayer pcb board manufacturing method and multilayer pcb board

A technology of PCB board and manufacturing method, which is applied in the field of electronic devices, can solve problems such as low production efficiency, expansion and contraction of inner layer boards, and increased difficulty of alignment, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

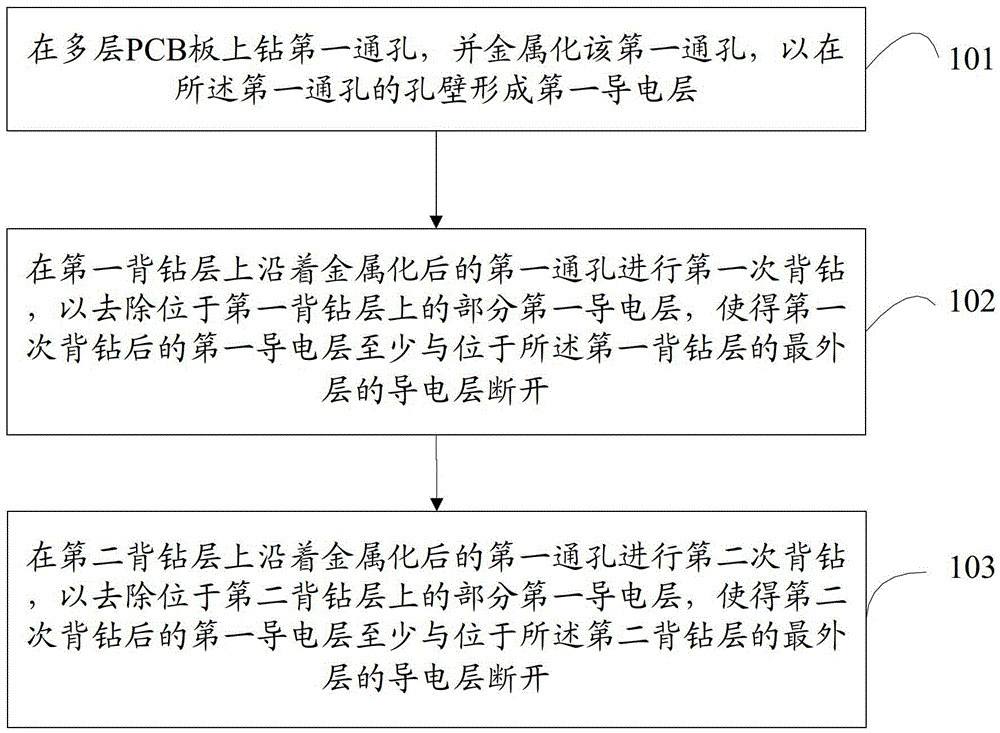

[0016] like figure 1 Shown, a kind of manufacturing method of multilayer PCB board comprises:

[0017] 101. Drill a first through hole on a multilayer PCB, and metallize the first through hole, so as to form a first conductive layer on a hole wall of the first through hole. Wherein, the multi-layer PCB board includes at least a first back-drilling layer and a second back-drilling layer with a conductive layer on the outermost layer, and at least two back-drilling layers arranged between the first back-drilling layer and the second back-drilling layer A stack of circuit layers, the first through hole runs through the first back-drilling layer, the stack and the second back-drilling layer.

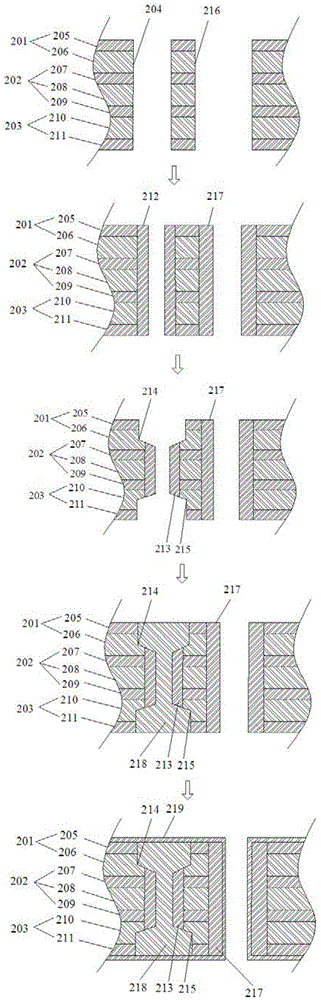

[0018] like figure 2 As shown, the multi-layer PCB board includes a first back-drilling layer 201 , a second back-drilling layer 203 and a laminated layer 202 disposed between the first back-drilling layer 201 and the second back-drilling layer 203 . Wherein, the first backdrilling layer...

Embodiment 2

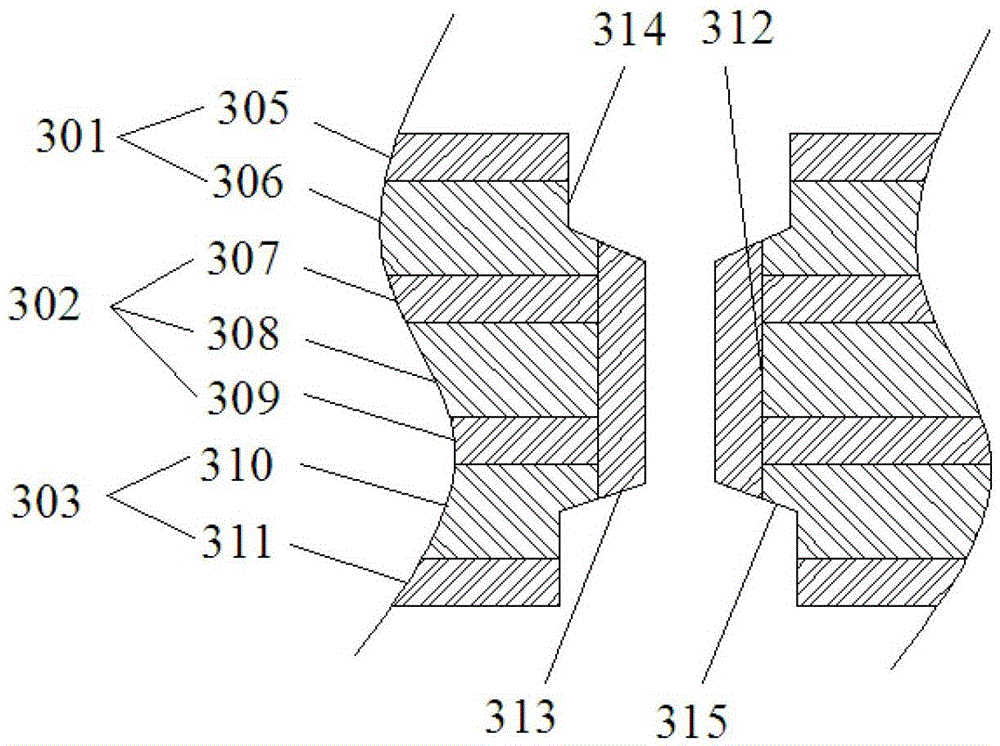

[0032] like image 3As shown, a multilayer PCB board includes a first back drill layer 301 with at least one outer conductive layer, a second back drill layer 303 with at least one outer conductive layer and a A laminated layer 302 having at least two circuit layers between the drill layer and the second back-drill layer. Wherein, the first backdrilling layer 301 includes a first insulating layer 306 and a first metal layer 305 disposed on the first insulating layer 306; The second metal layer 307 and the third metal layer 309 disposed on the lower surface of the second insulating layer 308; the second backdrilling layer 303 includes a third insulating layer 310 and a fourth metal layer 311 disposed on the lower surface of the third insulating layer 310 . The first back-drilled layer 301 is provided with a first back-drilled hole 314 , and the second back-drilled layer 303 is provided with a second back-drilled hole 315 opposite to the first back-drilled hole 314 . The lami...

Embodiment 3

[0035] like Figure 4 As shown, a multilayer PCB board includes a first back drill layer 401 with at least one outer conductive layer, a second back drill layer 403 with at least one outer conductive layer and a A laminated layer 402 having at least two circuit layers between the drill layer and the second back-drill layer. Wherein, the first backdrilling layer 401 includes a first insulating layer 406 and a first metal layer 405 disposed on the first insulating layer 406; The second metal layer 407 and the third metal layer 409 disposed on the lower surface of the second insulating layer 408; the second backdrilling layer 403 includes a third insulating layer 410 and a fourth metal layer 411 disposed on the lower surface of the third insulating layer 410 . The first back-drilling layer 401 is provided with a first back-drilling hole 414 , and the second back-drilling layer 403 is provided with a second back-drilling hole 415 opposite to the first back-drilling hole 414 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com