Wooden ground heating floor with heating function

A floor and wooden technology, applied in heating methods, lighting and heating equipment, household appliances, etc., can solve the problem of inability to control the heating temperature well, insufficient connection strength of adjacent floors, long distance between the floor and the floor heating pipe, etc. problems, to achieve the effect of enhancing installation stability and service life, good heating effect, and enhanced heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0018] Example.

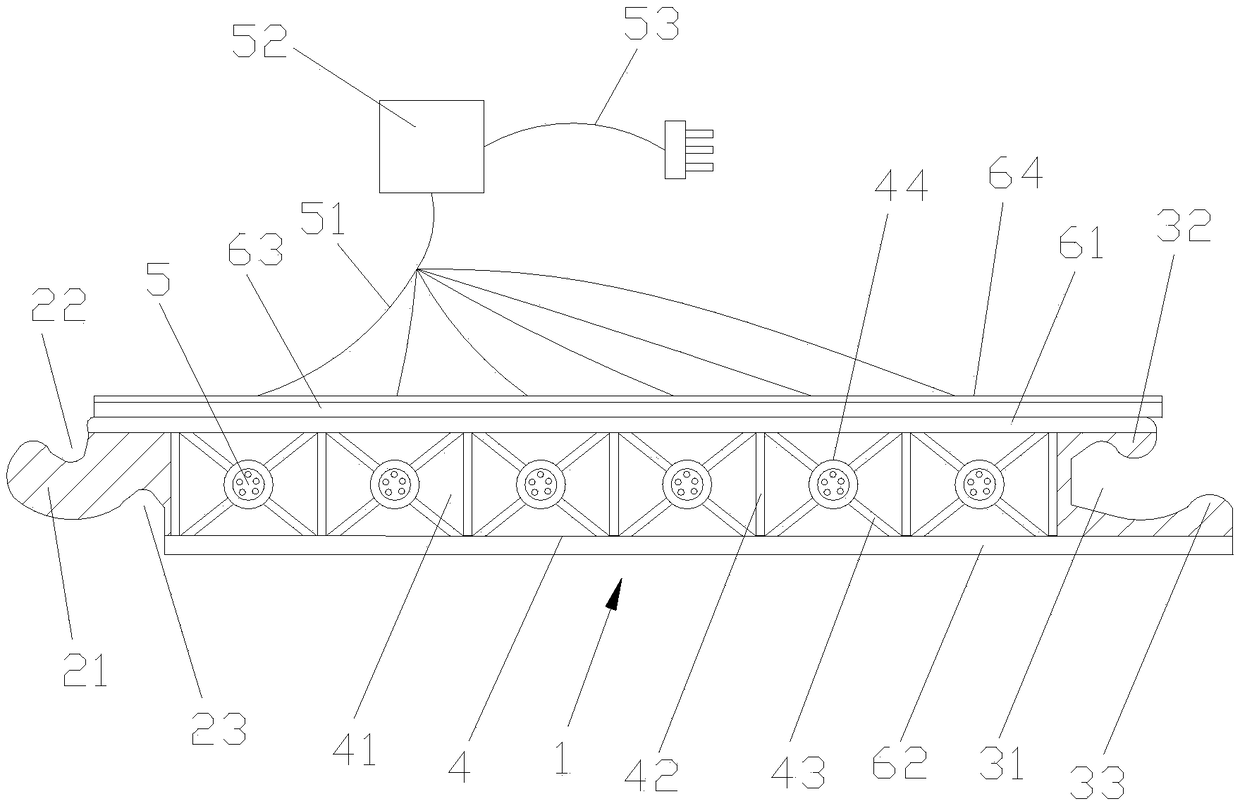

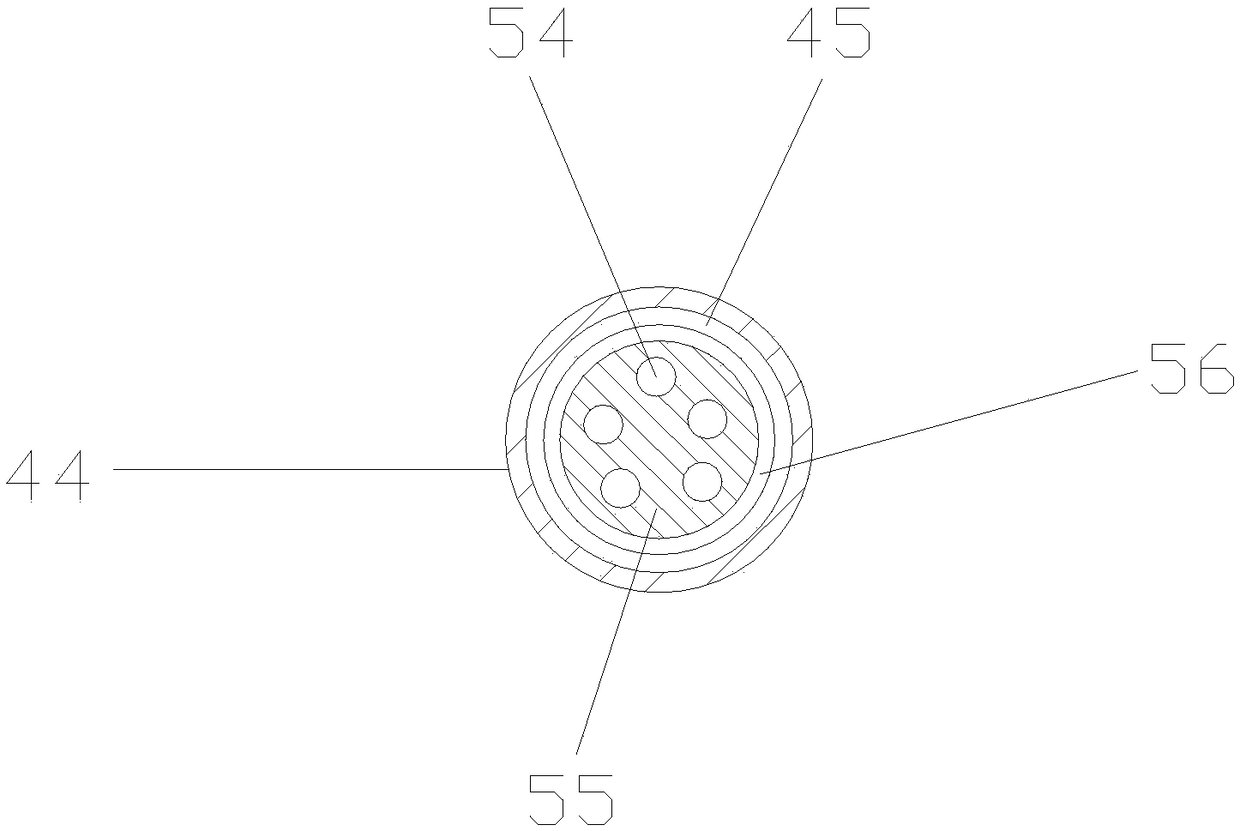

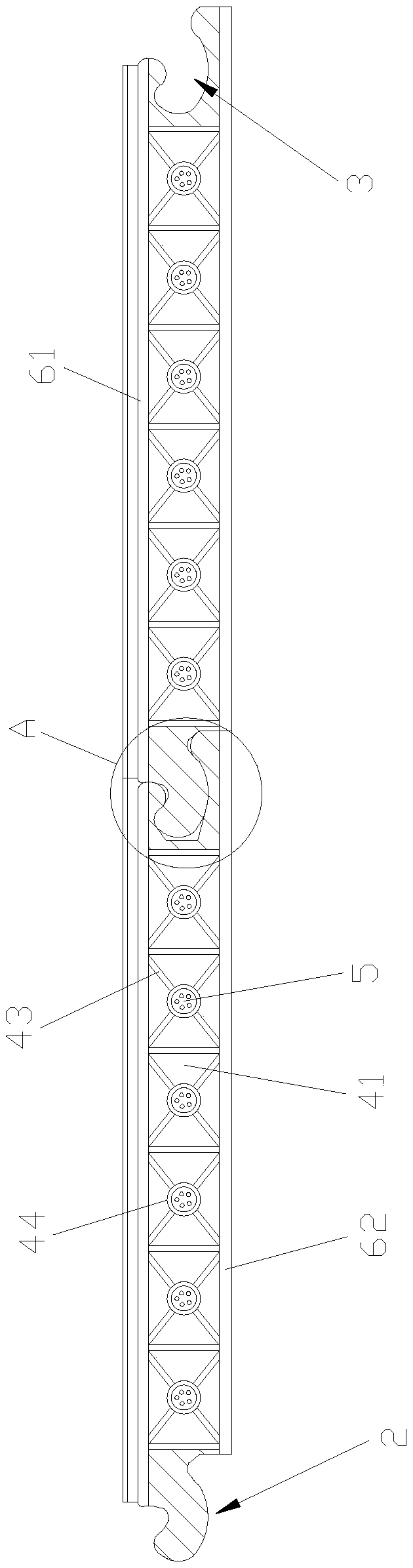

[0019] Such as Figure 1-4 As shown, a wooden floor heating with heating function includes a floor body 1, and two ends of the floor body 1 are respectively provided with a matching tongue 2 and a tongue groove 3, and the tongue 2 includes a connection extending outward Tongue 21, the upper end of connecting tongue 21 is provided with first groove 22, and the lower end of connecting groove 31 is provided with second groove 23; The upper end is provided with a first locking projection 32 matching the first groove 22, and the lower end of the connecting groove 31 is provided with a second locking projection 33 matching the second groove 23; A heating layer 4 is arranged inside, and a hollow groove 41 is arranged in the heating layer 4. A plurality of vertical isolation ribs 42 are arranged in the hollow groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com