A kind of preparation method of polybutene alloy material

A technology of polybutene alloy and butene, applied in the production of bulk chemicals, etc., to achieve the effect of improving equipment utilization and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

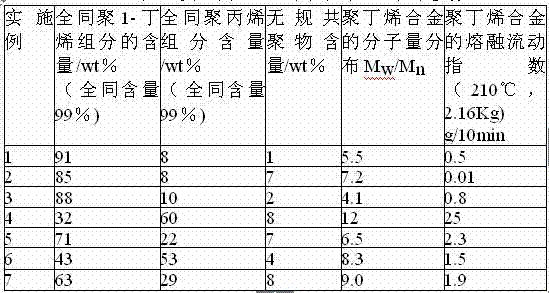

Examples

Embodiment 1

[0057] The first olefin tank of the present invention is opened to obtain the alloy product in the polypropylene kettle. In the reactor; the reactor for preparing polybutene alloy material by continuous process is a pilot plant with a production capacity of 25kg / h, consisting of three reactors in series, the first two are with mechanical stirring device and temperature control clamp Set of stainless steel pressure-resistant reactors, the latter is a gas-phase fluidized bed reactor. Co-catalyst triethylaluminum (5% by mass in hexane solution), external electron donor diisopropyldimethoxysilane (3% by mass in hexane solution), Ti-containing main catalyst (5% by mass) % Liquid paraffin mixture), liquid propylene, and hydrogen continuously enter the first reactor at a fixed rate to perform liquid phase bulk polymerization of propylene. At the same time, the materials in the first reactor flow out into the second reactor at a certain rate to continue the bulk polymerization of prop...

Embodiment 2

[0062] Using the same continuous polymerization reaction device and operating process as in Example 1, the co-catalyst was changed to triisobutyl aluminum (5% by mass in hexane solution), and the external electron donor was changed to methylcyclohexyldimethoxysilane (3% by mass in hexane solution), Ti-containing main catalyst (5% by mass of liquid paraffin mixture), liquid propylene, and hydrogen enter the first reactor continuously at a fixed rate for liquid phase bulk polymerization of propylene.

[0063] The molar ratio of Al element of triisobutyl aluminum to Ti element in the main catalyst is 80:1, and the molar ratio of Al element of triethylaluminum to external electron donor methylcyclohexyldimethoxysilane is 8: 1. Other conditions are the same as in Example 1.

[0064] The polymer product is free-flowing granular or spherical fine powder particles. The properties of the obtained polymer alloy are shown in Table 1.

Embodiment 3

[0066] Using the same continuous polymerization reaction device and operation process as in Example 1, the co-catalyst triethylaluminum (5% by mass in hexane solution), the external electron donor diisopropyldimethoxysilane (3% by mass) Hexane solution), Ti-containing main catalyst (5% by mass liquid paraffin mixture), liquid propylene, and hydrogen continuously enter the first reactor at a fixed rate to perform liquid phase bulk polymerization of propylene.

[0067] The molar ratio of Ti element to butene-1 in the main catalyst is 1×10 -6 :1, the molar ratio of Al in triethylaluminum to Ti in the main catalyst is 100:1, and the molar ratio of Al in triethylaluminum to the external electron donor diisopropyldimethoxysilane is 10:1, control the flow rate of monomer butene-1 entering the third tank so that the ratio of flow rate to propylene is 5:1.

[0068] The polymer product is free-flowing granular or spherical fine powder particles. The properties of the obtained polymer alloy a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com