Microalloyed mold steel with high purity and preparation method thereof

A technology of microalloying and purity, which is applied in the field of high purity microalloying die steel and its preparation, can solve the problems of difficult to ensure thermal stability, high content of Mo element, long production cycle, etc., and achieve small segregation, High purity and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

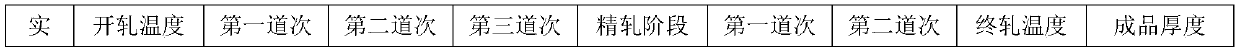

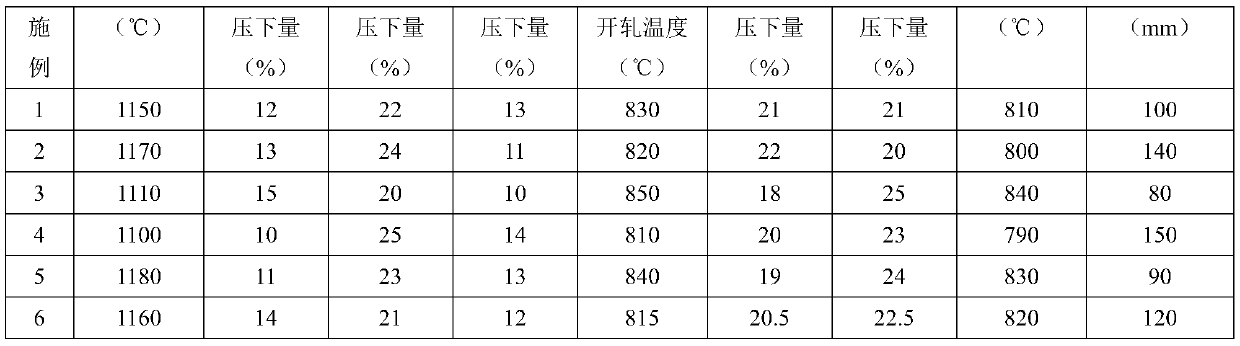

Examples

preparation example Construction

[0035] A preparation method of high-purity micro-alloyed mold steel, which is smelted by molten iron pretreatment-induction furnace smelting, poured into steel ingots, and put the steel ingots in an electroslag remelting device for secondary refining;

[0036] The electroslag remelting process has the effect of "slag washing" to remove various inclusions in the steel and good crystallization conditions, so that this kind of mold steel has good purity. The crystallization proceeds successively from bottom to top. The as-cast structure is fine, dense and uniform without white spots, porosity and shrinkage cavity, and the segregation is small. The metallographic structure and chemical composition of this product can be uniform, the surface is smooth, the sulfur content is extremely low, and the non-metallic inclusions are few and finely dispersed. The steel plate rolled by the steel ingot after electroslag remelting can greatly improve transverse plasticity and toughness, improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com