Environment-friendly water-based antirust agent and preparation method thereof

A water-based anti-rust agent, an environmentally friendly technology, applied in the direction of metal material coating technology, etc., can solve the problems of anti-rust performance decline, environmental pollution, human harm, etc., to achieve good anti-rust performance, wide applicability, anti-rust long term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] An environment-friendly water-based antirust agent, its raw material composition and mass ratio are:

[0014] 39kg deionized water, 7kg glycerin, 25kg diglycolamine, 8kg tartaric acid, 3kg itaconic acid, 0.5kg sodium molybdate, 1kg sodium tungstate, 6kg coconut acid diethanolamide 6501, 0.5kg weight of anhydrous sodium carbonate .

[0015] Among them, the manufacturer of coconut acid diethanolamide 6501 is Guangzhou Huayu Fine Chemical Co., Ltd., with a specification of 1:1.

[0016] A production method of an environment-friendly water-based antirust agent, comprising the following steps:

[0017] A. Add water, diglycolamine, tartaric acid, and itaconic acid to the reaction kettle according to the ratio and stir until the reactants are completely dissolved;

[0018] B. Add sodium molybdate and sodium tungstate according to the ratio, heat to 65°C and stir to dissolve, then add coconut acid diethanolamide 6501, glycerin and anhydrous sodium carbonate, stir and dissolve...

Embodiment 2

[0022] An environment-friendly water-based antirust agent, its raw material composition and mass ratio are:

[0023] 52kg deionized water, 6kg glycerin, 27kg diglycolamine, 4kg tartaric acid, 4.5kg itaconic acid, 1kg sodium molybdate, 0.5kg weight of sodium tungstate, 5kg cocoic acid diethanolamide 6501, 0.7kg anhydrous carbonic acid sodium.

[0024] The production method is generally the same as in Example 1, except that in step B, it is heated to 70° C. and stirred to dissolve.

Embodiment 3

[0028] An environment-friendly water-based antirust agent, its raw material composition and mass ratio are:

[0029] 56kg deionized water, 10kg glycerin, 22kg diglycolamine, 6kg tartaric acid, 2.5kg itaconic acid, 0.6kg sodium molybdate, 0.5kg sodium tungstate, 4kg coconut acid diethanolamide 6501, 0.5kg anhydrous sodium carbonate .

[0030] The production method is generally the same as that in Example 1, except that in step B, it is heated to 80° C. and stirred to dissolve.

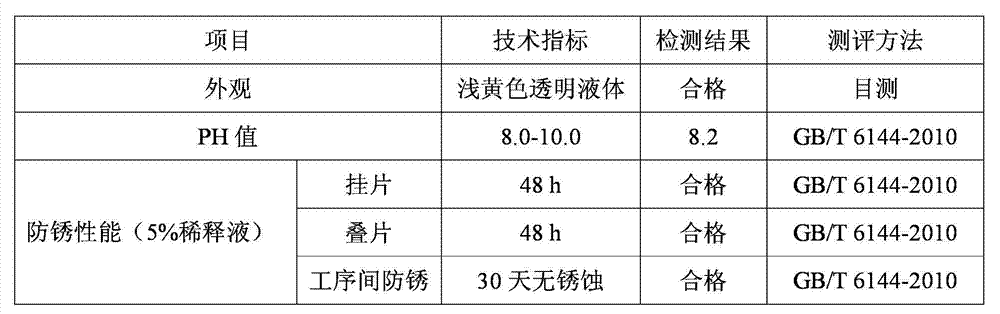

[0031] As an application example, the above-mentioned anti-rust agent is tested according to the specified standards, and the technical indicators are as follows:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com