Method for preparing novel sheet special for tobacco by replacing wood pulp fibers with cotton fibers

A wood pulp fiber and cotton fiber technology, applied in the field of tobacco, can solve the problems of easy-to-agglomerate products, discontinuous production, low filling value, etc., and achieve the effects of easy melting, improved sensory quality, and great cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pulverize the tobacco leaves into tobacco powder, the mesh size is greater than 100 mesh;

[0030] Uniformly mix the mixture of 100g smoke powder and 5g xanthan gum and konjac gum, wherein the mass ratio of xanthan gum and konjac gum is 1:1 to obtain the first mixture;

[0031] Take 2g of cotton fiber, 20g of water, 0.2g of polyethylene glycol 200, 30g of propylene glycol, and a mixture of propylene glycol, wherein the mass ratio of propylene glycol to glycerin is 1:1, heat it to 50°C in a reaction kettle, stir and mix evenly at high speed , decompose and disperse to obtain the second mixture;

[0032] Adding the second mixture into a homogeneous reactor and mixing it with the first mixture uniformly to obtain a mixed material;

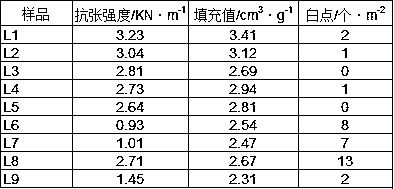

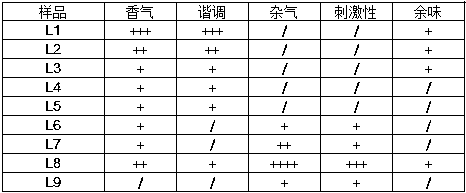

[0033] The mixed material is formed by a roller press, dried and cut into shreds, and prepared into a heat-not-burn tobacco product marked as L1. The physical properties are measured and made into an electric heating low-temperature cigarette ...

Embodiment 2

[0035] Pulverize the tobacco leaves into tobacco powder, the mesh size is greater than 100 mesh;

[0036] Uniformly mix 100g smoke powder with 5g konjac gum and sodium polyacrylate to obtain the first mixture;

[0037] Take 1.5g of cotton fiber, 0.15g of polyethylene glycol 200, 20g of water, 40g of the same amount of glycerol and ethylene glycol, heat them to 40°C in a reaction kettle, stir and mix evenly at a high speed, decompose and disperse to obtain the second mixture ;

[0038] Adding the second mixture into a homogeneous reactor and mixing it with the first mixture uniformly to obtain a mixed material;

[0039] The mixed material is formed by a roller press, dried and cut into shreds to prepare a heat-not-burn tobacco product marked as L2. Its physical properties are measured and made into an electric heating low-temperature cigarette for sensory smoking.

Embodiment 3

[0041] Pulverize the tobacco leaves into tobacco powder, the mesh size is greater than 100 mesh;

[0042] Uniformly mix 100g smoke powder and 5g chitin to obtain the first mixture;

[0043] Take 1g of cotton fiber, 0.1g of polyethylene glycol 400, 20g of water, and 40g of sorbitol in a reaction kettle and heat to 45°C, stir and mix evenly at high speed, dissolve and disperse to obtain the second mixture;

[0044] Adding the second mixture into a homogeneous reactor and mixing it with the first mixture uniformly to obtain a mixed material;

[0045] The mixed material is formed by a roller press, dried and cut into shreds, and prepared into a heat-not-burn tobacco product marked as L3. Its physical properties are measured and made into an electric heating low-temperature cigarette for sensory smoking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com