Easy-to-clean sanitary ceramic glaze, sanitary ceramic and preparation method

A sanitary ceramics and cleaning technology, which is applied in the glaze of sanitary ceramics and sanitary ceramics and preparation fields, can solve the problems of unsatisfactory antibacterial effect and high production cost, and achieve improved flatness and gloss, high smoothness and compactness, and wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Correspondingly, the present invention also provides a preparation method of sanitary ceramic products, comprising the following steps:

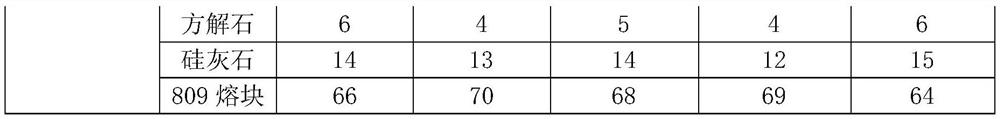

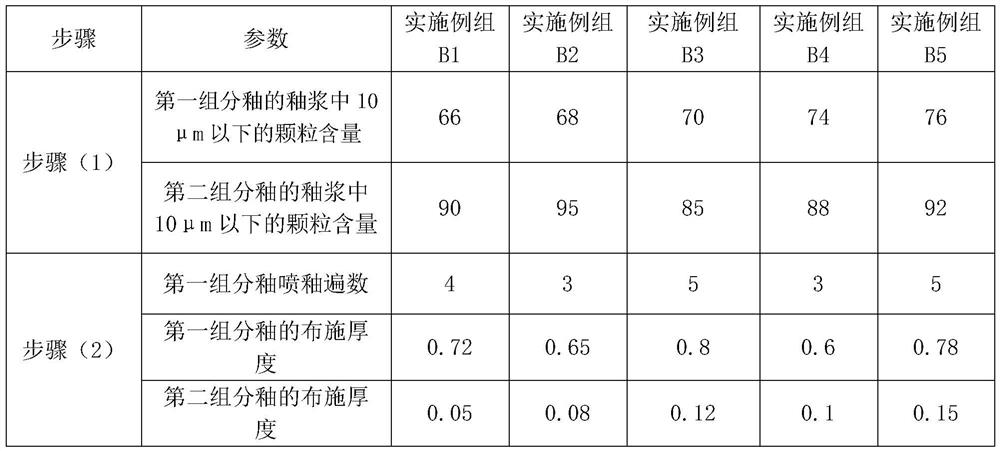

[0048] (1) The first component glaze and the second component glaze of the glaze of the above-mentioned easy-to-clean sanitary ceramics are respectively made into glaze slurry. The content of particles is 66-76%; the content of particles below 10 μm in the glaze slurry of the second component glaze is 85-95%;

[0049] (2) Adopt the method of spraying glaze, first spray the first component glaze on the surface of the forming body for 3-5 times, and then spread the second component glaze on the surface of the first component glaze;

[0050] (3) After drying, it is fired in a kiln.

[0051] The preparation method is simple, the raw materials are easy to obtain, and the popularization is strong. In the method of the present invention, the glaze slurry fineness of the first component glaze and the second component glaze is limited, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com