Monocrystalline silicon etching solution and application method thereof

A single crystal silicon texturing and texturing liquid technology, applied in chemical instruments and methods, crystal growth, final product manufacturing, etc. The effect of increasing nucleation density and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

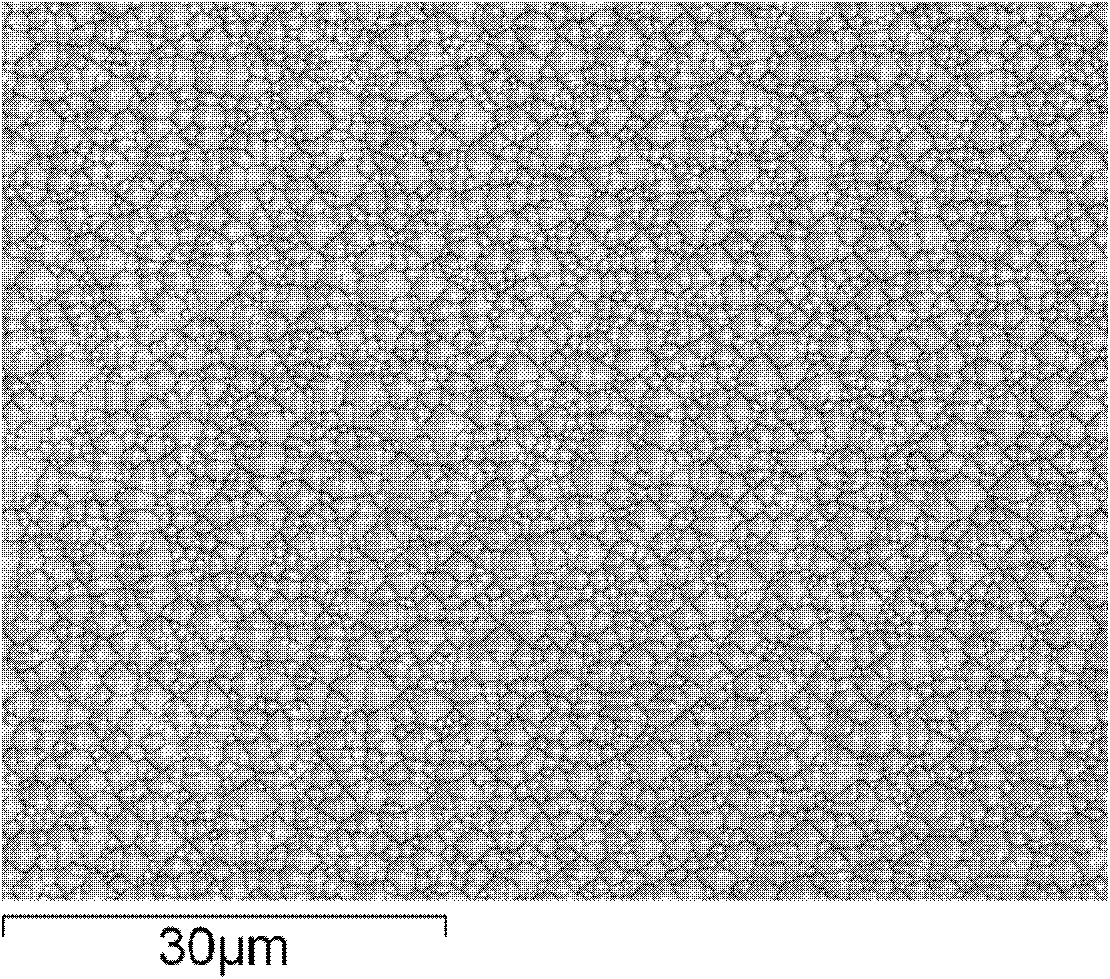

[0023] Embodiment 1: as figure 1 As shown, the monocrystalline silicon texturing solution of the present invention mainly consists of an inorganic alkaline etching solution, a surfactant and alcohols, wherein the inorganic alkaline etching solution is a 2% NaOH aqueous solution by mass percentage, and the surfactant Is the dispersant MF (its molecular formula is C 23 h 18 o 6 S 2 Na 2 ) and naphthalenesulfonic acid formaldehyde condensate, the mass ratio of the dispersant MF and naphthalenesulfonic acid formaldehyde condensate is 5:1, the content of the mixture is 0.3% of the quality of the alkaline corrosion solution, and the alcohols are ethylene glycol Alcohol, the content is 4% of the mass of alkaline corrosion solution.

[0024] When in use, keep the temperature of the texturing solution at 75-85°C, and the corrosion time for 10-20 minutes. The thinning of one side of the silicon wafer is about 3-8 μm.

Embodiment 2

[0025] Embodiment 2: The monocrystalline silicon texturizing liquid of the present invention is mainly composed of inorganic alkaline etching liquid, surfactant and alcohols, wherein the inorganic alkaline etching liquid is 0.4% KOH aqueous solution by mass percentage, and the surface active The agent is dispersant MF (its molecular formula is C 23 h 18 o 6 S 2 Na 2 ) and naphthalenesulfonic acid formaldehyde condensate, the mass ratio of the dispersant MF and naphthalenesulfonic acid formaldehyde condensate is 3:1, the content of the mixture is 0.02% of the alkaline corrosion liquid quality, and the alcohols are isopropyl Alcohol, the content is 0.1% of the mass of alkaline corrosion solution.

[0026] When in use, keep the temperature of the texturing solution at 75-85°C, and the corrosion time for 10-15 minutes. The thinning of one side of the silicon wafer is about 3-8 μm.

Embodiment 3

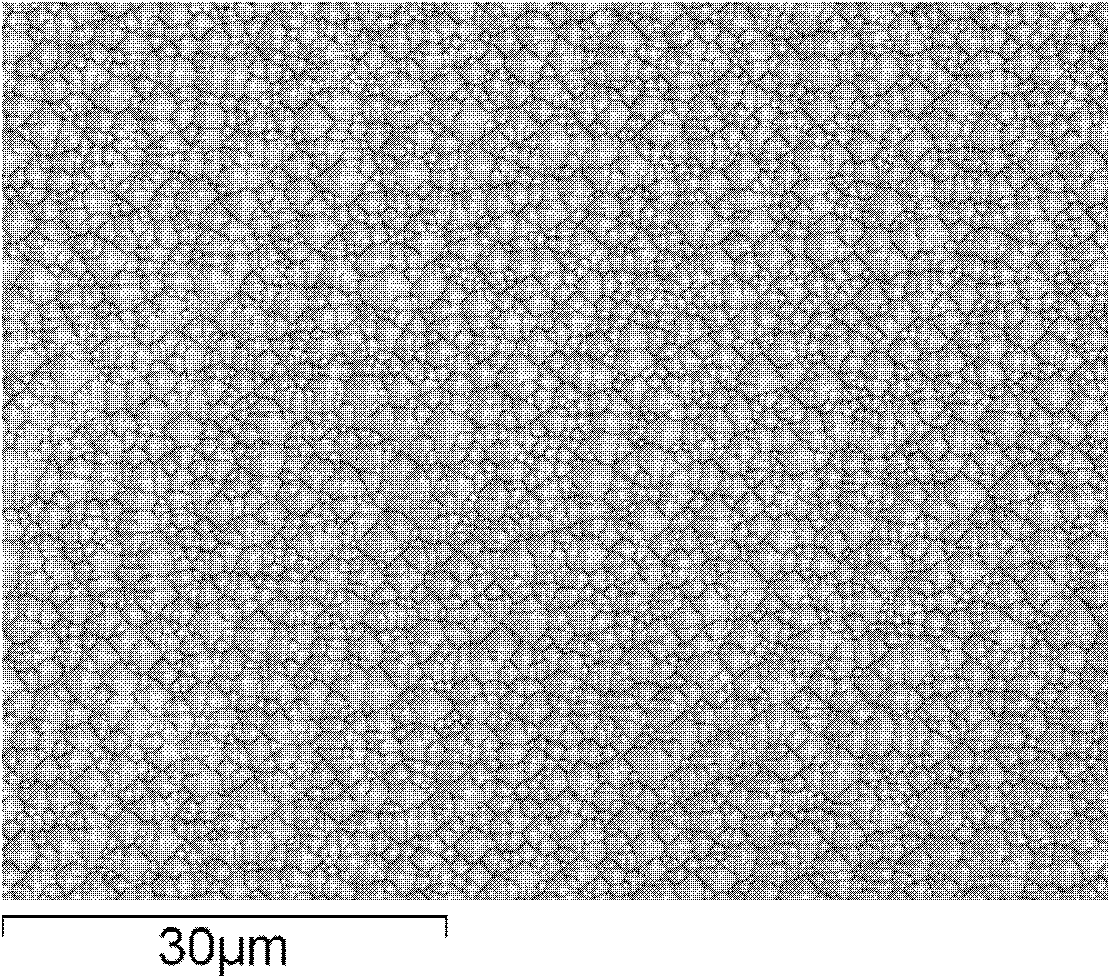

[0027] Embodiment 3: The monocrystalline silicon texturing liquid of the present invention mainly consists of inorganic alkaline etching liquid, surfactant and alcohols, wherein the inorganic alkaline etching liquid is 4.5% by mass percentage of NaOH and NaOH 2 SiO 3 The mixed aqueous solution, the surfactant is a dispersant MF (its molecular formula is C 23 h 18 o 6 S 2 Na 2 ) and naphthalenesulfonic acid formaldehyde condensate, the mass ratio of the dispersant MF and naphthalenesulfonic acid formaldehyde condensate is 4:1, the mixture content is 0.6% of the alkaline corrosion liquid quality, the alcohols are ethanol, The content is 8% of the mass of alkaline corrosion solution.

[0028] When in use, keep the temperature of the texturing solution at 75-85°C, and the corrosion time for 10-15 minutes. The thinning of one side of the silicon wafer is about 3-8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com