Production method for preparing resistant rice starch

A technology of resistant starch and rice starch, applied in protein food processing, food science, protein food ingredients, etc., can solve problems such as lack of mature technology, and achieve the effect of increasing farmers' income, improving life, and reducing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The production method for preparing rice resistant starch of the present invention comprises the steps of gelatinizing rice starch, debranching, crystallizing, and extracting, and finally drying the extracted rice resistant starch to obtain rice resistant starch , wherein the amylose content in the rice starch is increased by debranching the gelatinized rice starch, the process parameters of the debranching process are: control the gelatinized rice starch concentration at 20% to 50%, debranching The enzyme addition amount is 12-25U / g, the debranching temperature is controlled at 45-55°C, and the debranching time is 12-20 hours; after the debranching treatment is completed, crystallize at 2-12°C, and then extract rice resistant starch , Dry at 50-70°C.

Embodiment 2

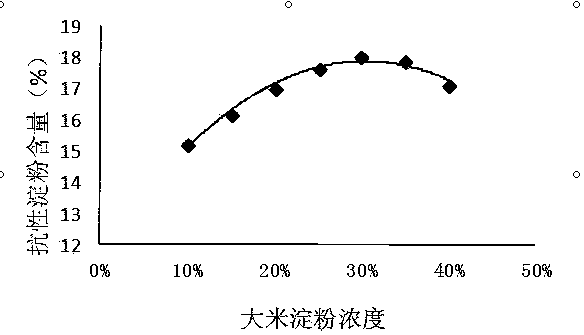

[0037] The production method of rice resistant starch of this embodiment is different from that of Example 1 in that: the gelatinization process of rice starch is controlled at 30% to 40% of the rice starch concentration, and is controlled under a neutral pH value. The gelatinization temperature is 130-150°C, the gelatinization and autoclaving time is controlled at 10-40 minutes, then cooled to 45-55°C, the pH value is adjusted to 4-5, and the moisture reaches 60%-70% by flash evaporation, and then Perform detachment.

Embodiment 3

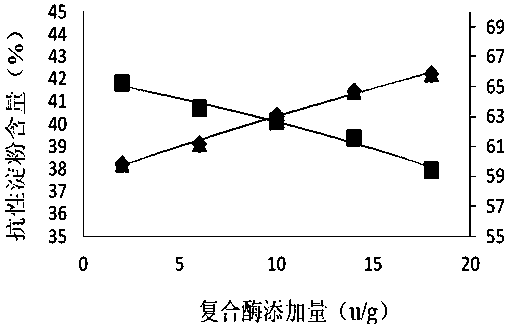

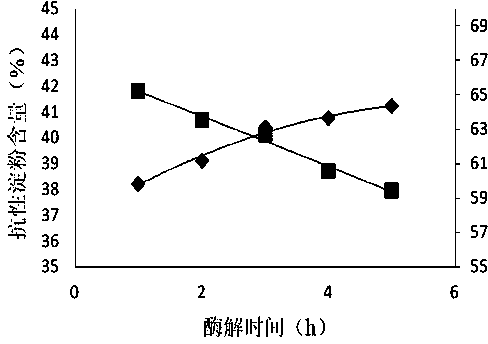

[0039] The difference between the production method of rice resistant starch in this example and Example 1 or Example 2 is that the extraction process of rice resistant starch uses the synergistic effect of β-amylase and glucoamylase to prepare a compound enzyme, so that The content of the resistant starch reaches 40%, and the yield reaches 60%, wherein the addition amount of the compound enzyme is 5-55U / g, and the enzymolysis time is 2-4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com