Method for preparing BiOI/WO3 composite heterojunction photocatalyst

A composite photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low catalytic activity and achieve good dispersion, complete crystallization, and regular morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1B

[0020] Example 1BiOI / WO 3 Preparation of nanorods

[0021] Measure 2mmol of sodium tungstate and add it to a beaker containing 25ml of deionized water, adjust the pH value of the mixed solution to 1 with concentrated nitric acid with a mass fraction of about 65%, stir it magnetically, and then hydrothermally react at 180°C for 24 hours , the precipitate obtained by centrifuging and washing with water, and drying at 60°C to obtain tungsten oxide; take the prepared tungsten oxide and dissolve it in deionized water, ultrasonically disperse it, and add equimolar potassium iodide and bismuth nitrate under the condition of stirring to control the concentration of bismuth nitrate and bismuth nitrate The molar ratios of tungsten oxide are 0.25, 0.5, 1.0, 1.5 and 2.0 respectively. After stirring and mixing evenly, the obtained yellow product is washed with deionized water and ethanol, filtered, and dried in a constant temperature drying oven at 60°C.

Embodiment 2B

[0022] Example 2BiOI / WO 3 Characterization and Analysis of Heterojunction Composite Photocatalysts

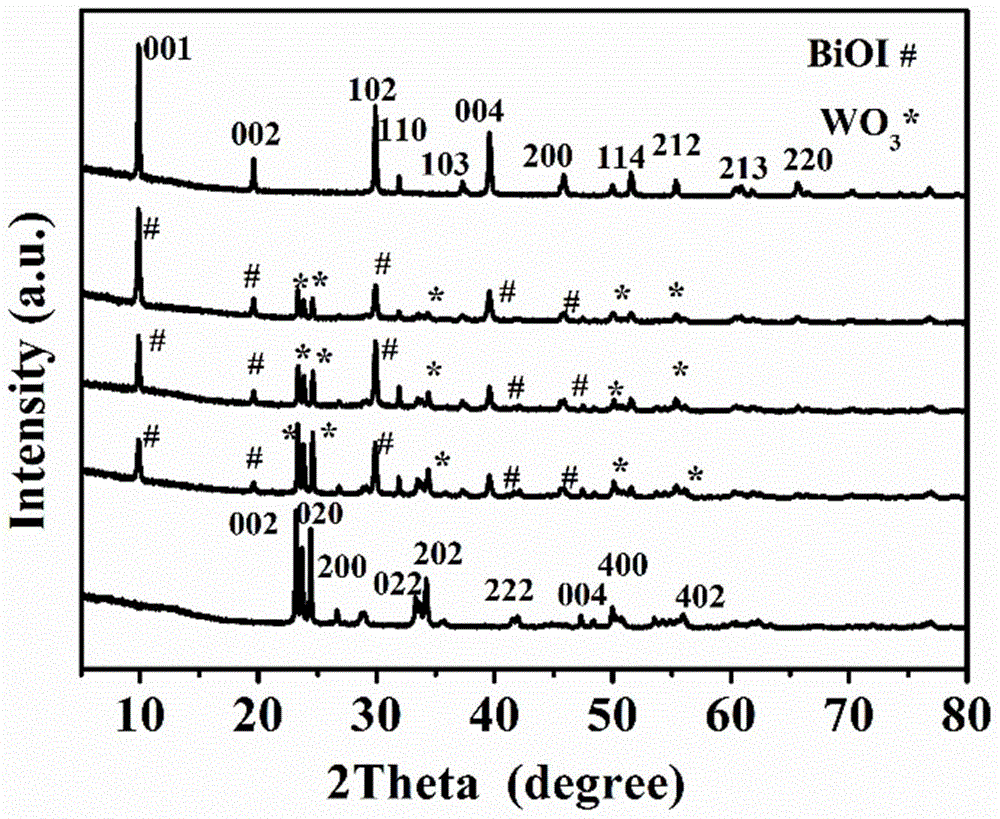

[0023] like figure 1 As shown, it can be seen from the figure that the composite sample has both BiOI and WO 3 The characteristic peaks indicate that we have successfully prepared BiOI / WO 3 Heterojunction composite photocatalysts.

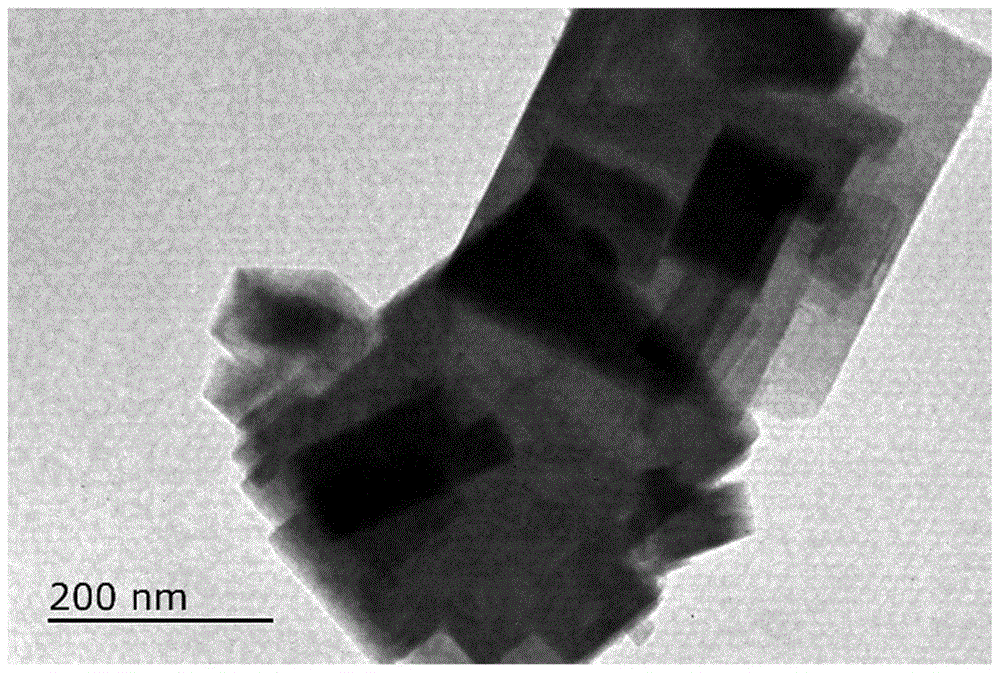

[0024] like image 3 As shown, it can be seen that bismuth oxyiodide particles loaded on pure WO 3 the surface of the nanosheets.

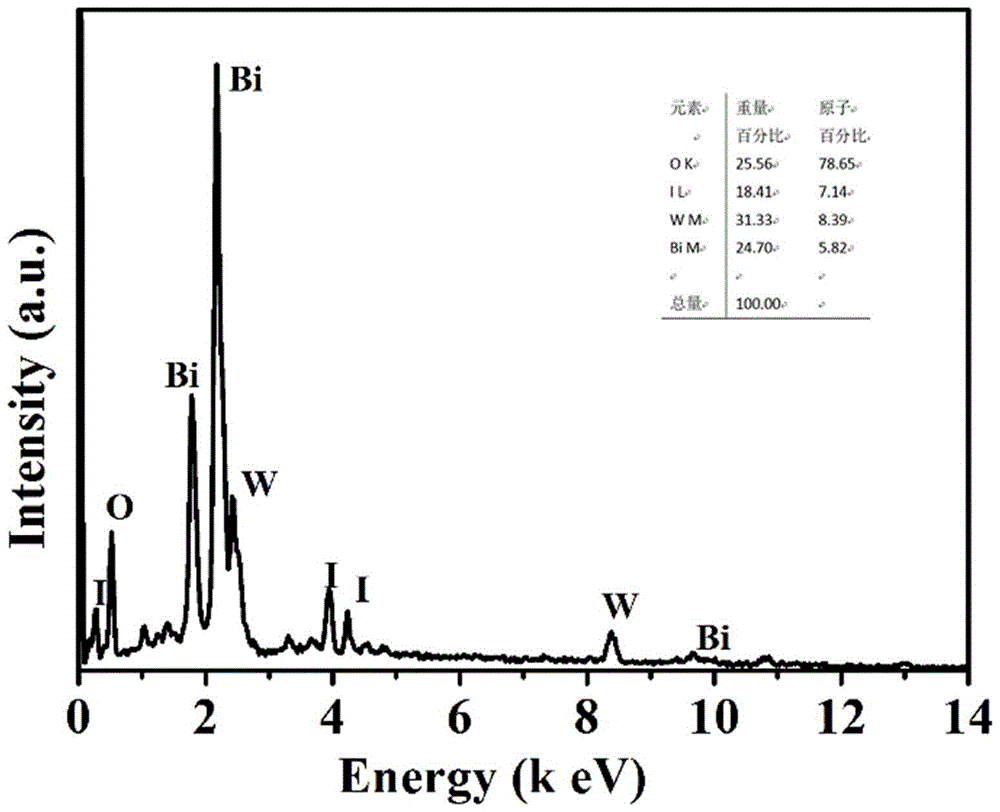

[0025] like figure 2 As shown, the spectrum shows the presence of Bi, O, I, W, O elements.

[0026] like Figure 5 As shown in the figure, it can be clearly seen that after four cycles of experiments, the photocatalytic performance of the catalyst did not decrease significantly.

Embodiment 3B

[0027] Example 3BiOI / WO 3 Visible light catalytic activity experiments of heterojunction composite photocatalysts

[0028] (1) Prepare a rhodamine B solution with a concentration of 10 mg / L, and place the prepared solution in a dark place.

[0029] (2) Weigh BiOI / WO 3 Heterojunction composite photocatalyst 100mg (when bismuth nitrate and WO 3 The molar ratio is 0.25:1, 0.5:1, 1.0:1, 1.5:1, 2.0:1, and the obtained samples are recorded as BW-0.25, BW-0.5, BW-1.0, BW-1.5, BW-2.0) , respectively placed in the photocatalytic reactor, add 100mL of the target degradation solution prepared in step (1), and stir magnetically for 30 minutes. After the composite photocatalyst is dispersed evenly, turn on the water source and the light source to conduct the photocatalytic degradation experiment.

[0030] (3) Absorb the photocatalytic degradation liquid in the reactor every 20 minutes, and use it for the measurement of the ultraviolet-visible absorbance after centrifugation.

[0031] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com