Luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot and preparation method thereof

A technology of cadmium sulfide and quantum dots, applied in cadmium sulfide, chemical instruments and methods, luminescent materials, etc., can solve the problems of harsh conditions, phase separation, difficult to scale up production, etc., achieve mild reaction conditions, overcome phase separation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

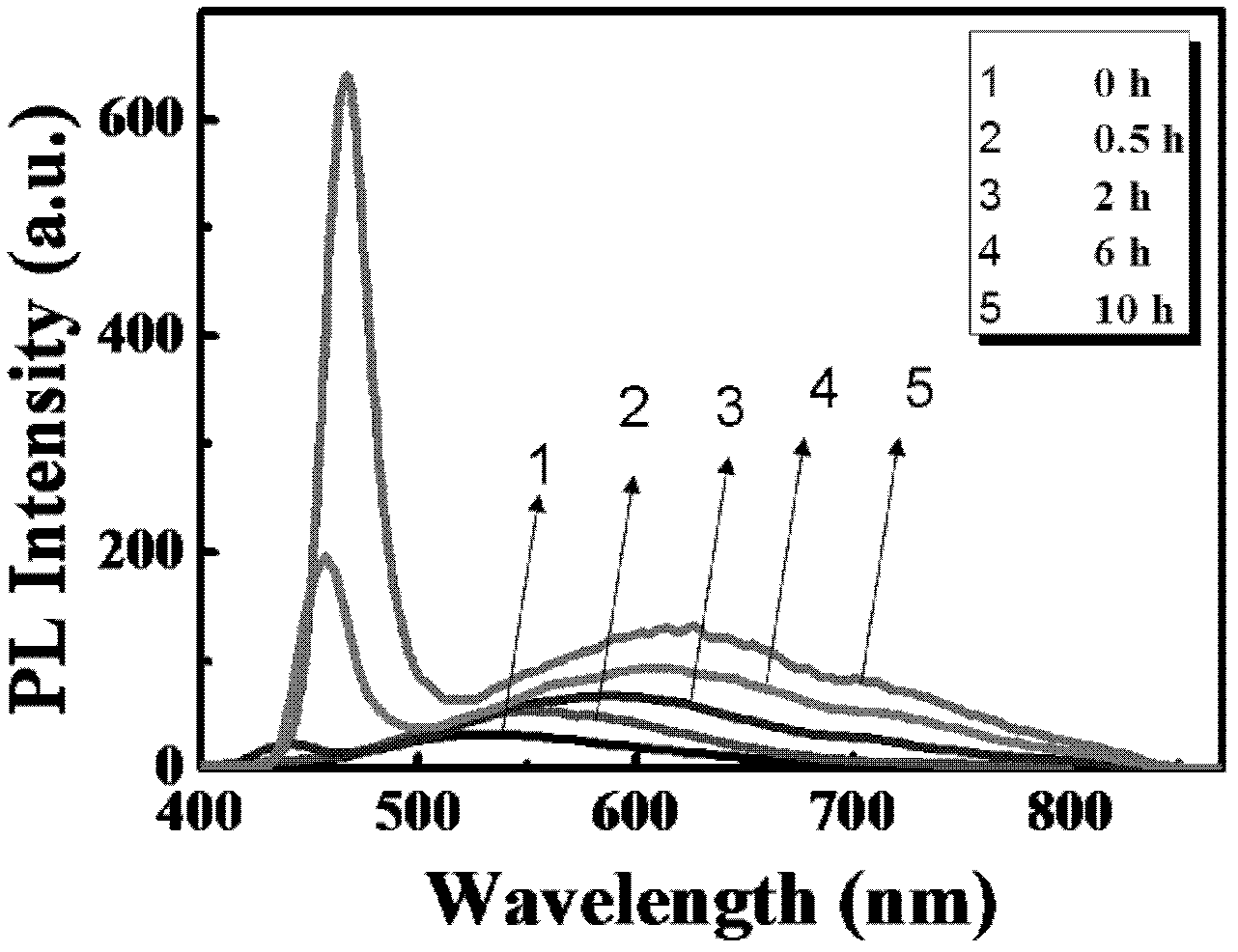

[0029] Weigh 0.005g of sodium sulfide and fully dissolve it with a small amount of deionized water. Weigh 0.053g of cadmium acetate and add it to 80mL N, N-dimethylformamide (DMF), stir magnetically, and after fully dissolving, add the sulfur source dropwise to the cadmium source; transfer the above precursor mixed solution In the alloy steel hydrothermal kettle of 100mL polytetrafluoroethylene substrate, put into oven and carry out solvothermal reaction 0 hour under 90 ℃, obtain the yellow transparent sol that contains the cadmium sulfide semiconductor quantum dot that does not have ligand wrapping, and this sol has The typical exciton absorption peak is weaker yellowish under UV light. The obtained solution is centrifuged to remove the precipitate, the supernatant is separated, the filtrate is collected, and dried to obtain the cadmium sulfide semiconductor quantum dot powder.

Embodiment 2

[0031] Weigh 0.005g of sodium sulfide and fully dissolve it with a small amount of deionized water. Weigh 0.053g of cadmium acetate and add it to 80mL N, N-dimethylformamide (DMF), stir magnetically, and after fully dissolving, add the sulfur source dropwise to the cadmium source; transfer the above precursor mixed solution Put it into an alloy steel hydrothermal kettle with a polytetrafluoroethylene substrate of 100mL, put it into an oven at 90°C and carry out solvothermal reaction for 0.5 hour, and obtain a yellow transparent sol containing cadmium sulfide semiconductor quantum dots without ligand wrapping. The sol has The typical exciton absorption peak shows strong yellow light under ultraviolet light. The obtained solution is centrifuged to remove the precipitate, the supernatant is separated, the filtrate is collected, and dried to obtain the cadmium sulfide semiconductor quantum dot powder.

Embodiment 3

[0033] Weigh 0.005g of sodium sulfide and fully dissolve it with a small amount of deionized water. Weigh 0.053g of cadmium acetate and add it to 80mL N, N-dimethylformamide (DMF), stir magnetically, and after fully dissolving, add the sulfur source dropwise to the cadmium source; transfer the above precursor mixed solution Put it into an alloy steel hydrothermal kettle with a polytetrafluoroethylene substrate of 100mL, put it into an oven at 90°C and carry out solvothermal reaction for 2 hours, and obtain a yellow transparent sol containing cadmium sulfide semiconductor quantum dots without ligand wrapping. The sol has The typical exciton absorption peak is a strong orange-yellow under UV light. The obtained solution is centrifuged to remove the precipitate, the supernatant is separated, the filtrate is collected, and dried to obtain the cadmium sulfide semiconductor quantum dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com