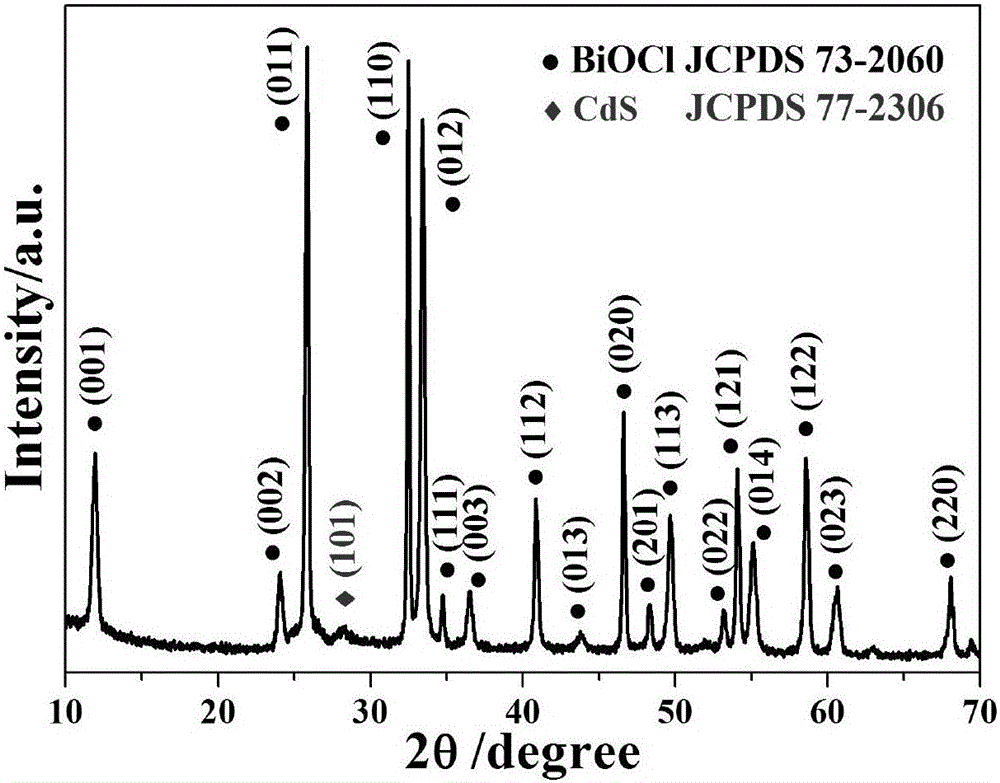

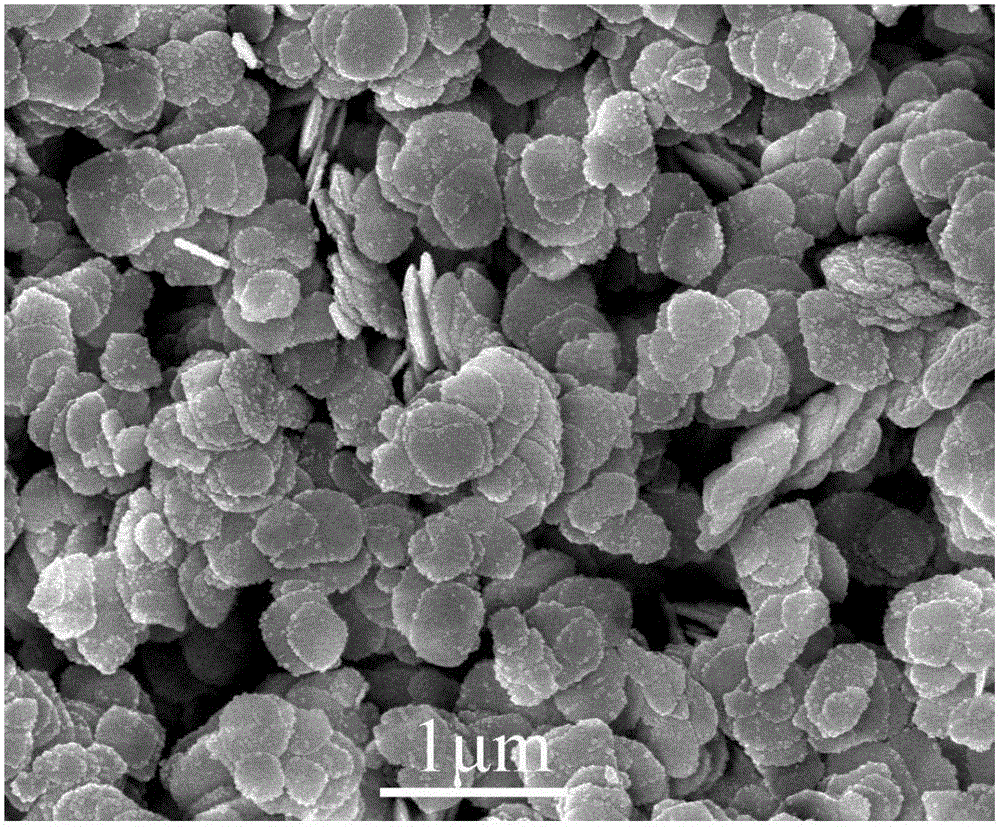

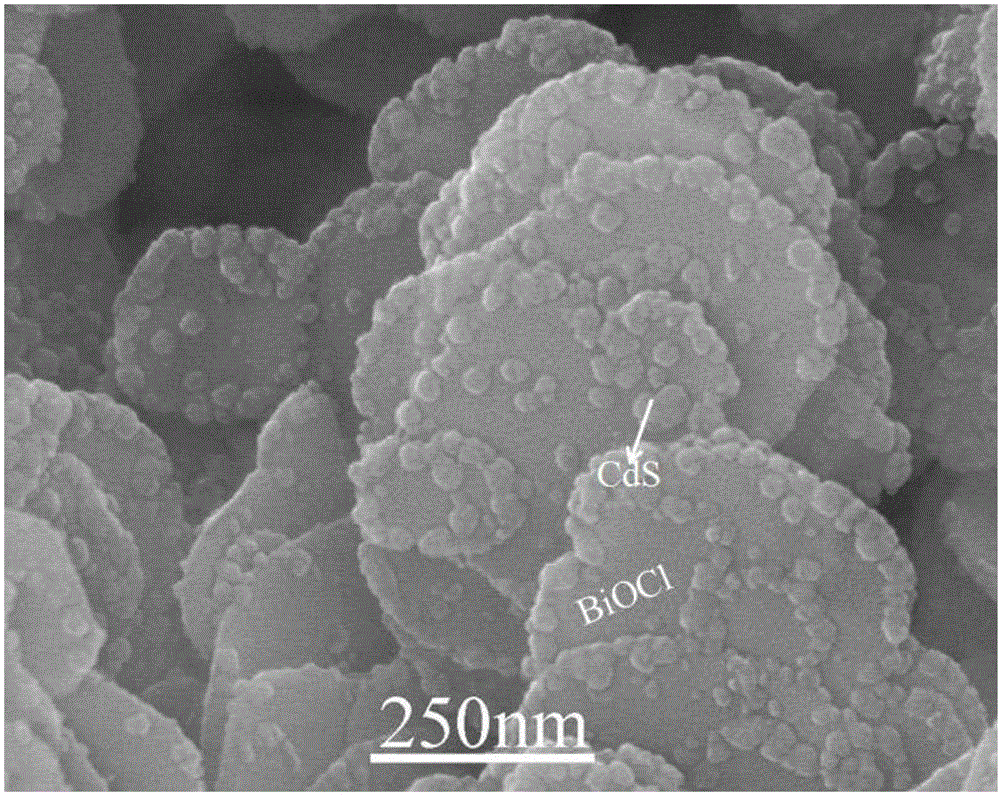

Flaky CdS/BiOCl composite nanometer material and preparation method thereof

A composite nanomaterial and sheet-like technology is applied in the field of composite photocatalyst preparation, which can solve the problems of photocatalyst photocorrosion and unstable CdS, and achieve the effects of low cost and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The flaky CdS / BiOCl composite nanomaterial of the present invention is prepared by microwave-assisted chemical synthesis technology, and its specific process is as follows:

[0025] (1) Weigh 1mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 (0), add 10mL ethanol, stir and dissolve to obtain bismuth nitrate solution, take by weighing 2mmol sodium chloride (NaCl), add 50mL deionized water, stir and dissolve to obtain sodium chloride solution;

[0026] (2) Mix the above two solutions, stir them magnetically for 15 minutes, place the reaction mixture in a household microwave oven, set the low heat to heat for 20 minutes, naturally cool to room temperature, filter, wash, and dry to obtain BiOCl nanopowder;

[0027] (3) Weigh 0.2g BiOCl, add to 30mL containing 0.6mmol cadmium acetate (Cd(CH 3 COO) 2 2H 2 O) in an aqueous solution, ultrasonically disperse for 15 minutes to obtain dispersion A;

[0028] (4) Weigh 1.0 mmol thiourea, add 30 mL deionized water, and dissolve to obtai...

Embodiment 2

[0035] The flaky CdS / BiOCl composite nanomaterial of the present invention is prepared by microwave-assisted chemical synthesis technology, and its specific process is as follows:

[0036] (1) Weigh 1mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 (0), add 10mL ethanol, stir and dissolve to obtain bismuth nitrate solution, take by weighing 2mmol sodium chloride (NaCl), add 50mL deionized water, stir and dissolve to obtain sodium chloride solution;

[0037] (2) Mix the above two solutions, stir them magnetically for 20 minutes, place the reaction mixture in a household microwave oven, set the low heat to heat for 20 minutes, cool naturally to room temperature, filter, wash, and dry to obtain BiOCl nanopowder;

[0038] (3) Weigh 0.2g BiOCl, add to 30mL containing 1.0mmol cadmium acetate (Cd(CH 3 COO) 2 2H 2 O) in an aqueous solution, ultrasonically disperse for 20 minutes to obtain dispersion A;

[0039] (4) Weigh 1.2mmol thiourea, add 30mL deionized water, and dissolve to obtain ...

Embodiment 3

[0044] The flaky CdS / BiOCl composite nanomaterial of the present invention is prepared by microwave-assisted chemical synthesis technology, and its specific process is as follows:

[0045] (1) Weigh 1mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 (0), add 10mL ethanol, stir and dissolve to obtain bismuth nitrate solution, take by weighing 2mmol sodium chloride (NaCl), add 50mL deionized water, stir and dissolve to obtain sodium chloride solution;

[0046] (2) Mix the above two solutions, stir them magnetically for 20 minutes, place the reaction mixture in a household microwave oven, set the low heat to heat for 20 minutes, naturally cool to room temperature, suction filter, wash, and dry to obtain BiOCl nanopowder;

[0047] (3) Weigh 0.2g BiOCl, add to 30mL containing 1.4mmol cadmium acetate (Cd(CH 3 COO) 2 2H 2 O) in an aqueous solution, ultrasonically disperse for 20 minutes to obtain dispersion A;

[0048] (4) Weigh 1.5mmol thiourea, add 30mL deionized water, and dissolve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com