Cadmium sulfide coating carbon nano tube gas-sensitive material and manufacture method of gas-sensitive element

A technology of gas-sensing materials and manufacturing methods, applied in the direction of material resistance, etc., can solve the problems of rare cadmium sulfide gas-sensing materials, low cadmium sulfide carrier density, increased material instability, etc., and achieve fast response and recovery speed , the synthesis method is simple and easy, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

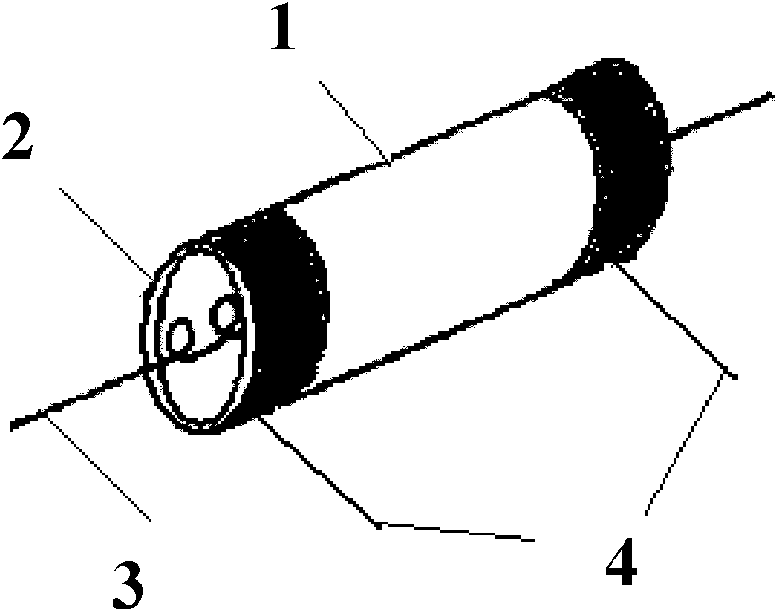

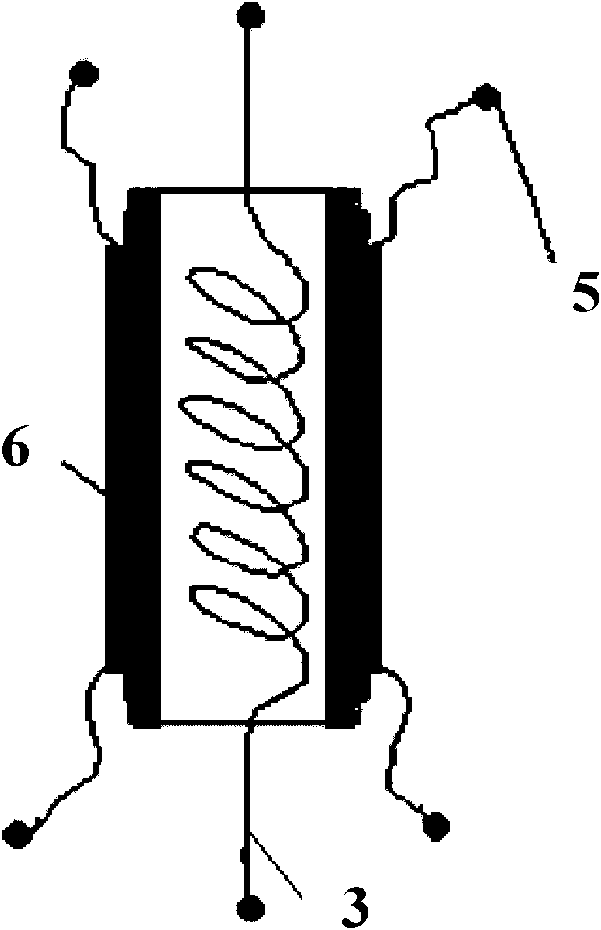

[0021] Embodiment 1: 0.1g diameter 40~60nm, multi-walled carbon nanotube of length 5~15 microns is placed in the 250mL Erlenmeyer flask that is placed the distilled water of 80-100mL, at room temperature at 100W, 40Hz ultrasonic dispersion 5- After 10 minutes, add 0.375g of thioacetamide, then ultrasonically disperse for 3~4min, then add 1.33g of cadmium acetate and ultrasonically disperse for 30min, then reflux in a water bath at 60℃~90℃ for 0.5~6 hours, cool, filter and wash thoroughly dry. The powder synthesized by this method (this powder is cadmium sulfide coated carbon nanotube gas-sensitive material) is prepared into a slurry with glycerin, and then coated on an Al alloy with a heating wire and a gold or platinum electrode. 2 o 3 On ceramic tubes, see figure 1 and figure 2 , sintering at a constant temperature of 400-500°C for 2-5 hours, then soldering, packaging, and electrical aging, that is, to obtain a side-heated gas sensor with high sensitivity to ethanol and ...

Embodiment 2

[0022]Example 2: Place 0.1 g of multi-walled carbon nanotubes with a diameter of 40-60 nm and a length of 5-15 microns in a 250-mL Erlenmeyer flask with 100 mL of distilled water, after 5-10 min of ultrasonic dispersion at 100 W and 40 Hz at room temperature , add 0.45g of thioacetamide and then ultrasonically disperse for 3~4min, then add 1.33g of cadmium acetate and ultrasonically disperse for 30min, then bathe in water at 60°C--90°C for 0.5~6 hours, cool and filter and fully wash and dry. The powder synthesized by this method (this powder is cadmium sulfide coated carbon nanotube gas-sensitive material) is prepared into a slurry with glycerin, and then coated on an Al alloy with a heating wire and a gold or platinum electrode. 2 o 3 On ceramic tubes, see figure 1 and figure 2 , sintering at a constant temperature of 400-500°C for 2-5 hours, then soldering, packaging, and electrical aging, that is, to obtain a side-heated gas sensor with high sensitivity to ethanol and go...

Embodiment 3

[0023] Example 3: 0.1 g of multi-walled carbon nanotubes with a diameter of 40 to 60 nm and a length of 5 to 15 microns are placed in a 250 mL Erlenmeyer flask with 100 mL of distilled water, and after 5-10 min of ultrasonic dispersion at 100 W and 40 Hz at room temperature , add 0.563g of thioacetamide and then ultrasonically disperse for 3~4min, then add 1.33g of cadmium acetate and ultrasonically disperse for 30min, then put in a water bath at 60°C-90°C for 0.5~6 hours, cool and filter and fully wash and dry. The powder synthesized by this method (this powder is cadmium sulfide coated carbon nanotube gas-sensitive material) is prepared into a slurry with glycerin, and then coated on an Al alloy with a heating wire and a gold or platinum electrode. 2 o 3 On ceramic tubes, see figure 1 and figure 2 , sintering at a constant temperature of 400-500°C for 2-5 hours, then soldering, packaging, and electrical aging, that is, to obtain a side-heated gas sensor with high sensitiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com