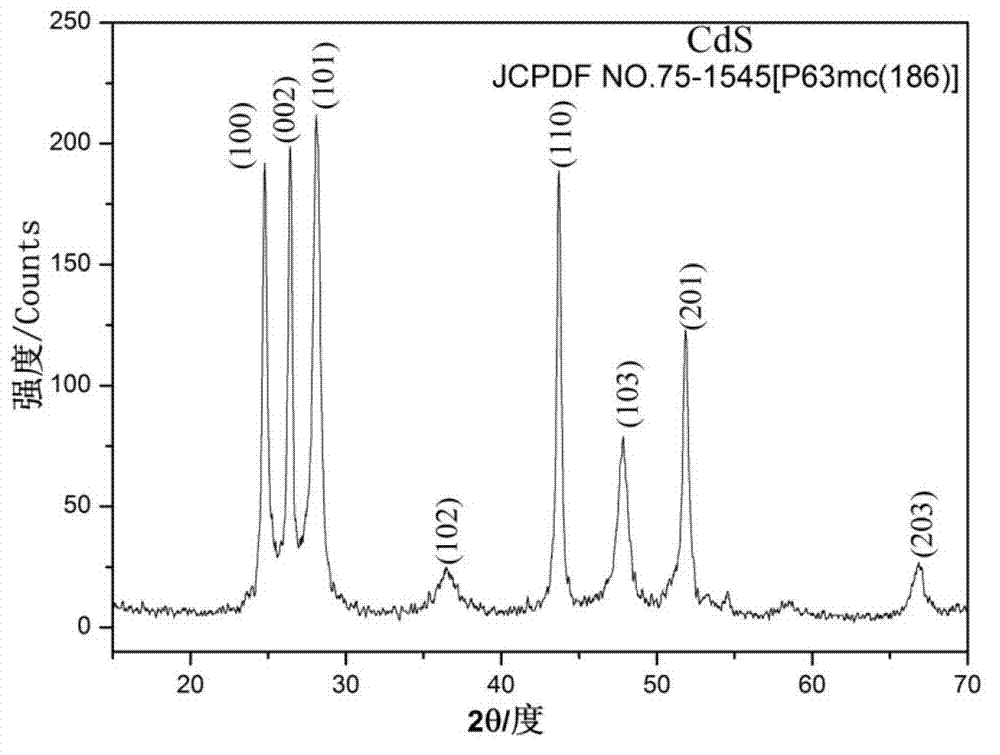

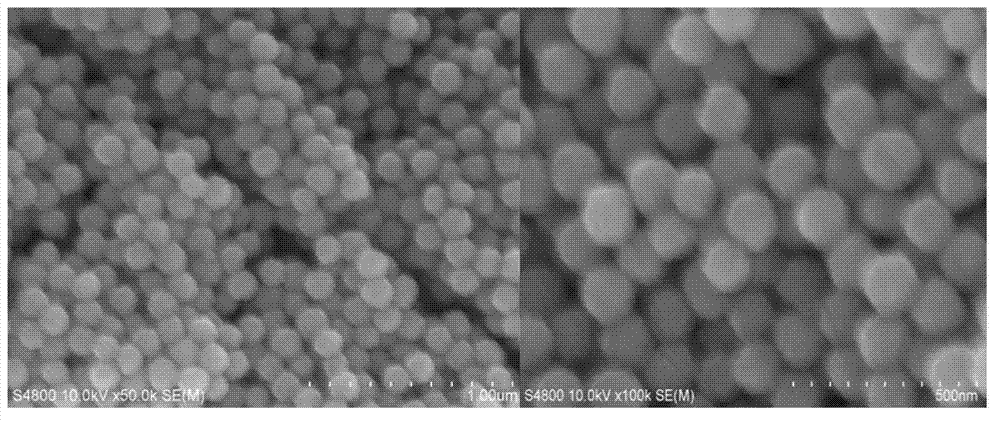

Method for preparing monodisperse cadmium sulfide nanospheres

A technology of nanospheres and cadmium sulfide, applied in cadmium sulfide, nanotechnology, nanotechnology, etc., can solve the problems of low raw material utilization, poor repeatability, and high equipment requirements, and achieve short preparation cycle, high repeatability, and required temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) The analytically pure cadmium acetate dihydrate (C 4 h 6 CdO 4 2H 2 O) added to deionized water, and kept stirring, configured as Cd 2+ A transparent solution A with a concentration of 0.2mol / L;

[0023] 2) The analytically pure thiourea (CH 4 N 2 S) added to deionized water, and kept stirring, configured as S 2- A transparent solution B with a concentration of 0.6mol / L;

[0024] 3) Slowly add an equal volume of solution B to solution A under strong stirring, and then ultrasonically disperse to obtain solution C;

[0025] 4) Prepare PVP solution D with a concentration of 0.1mol / L, and mix solution C and solution D at a volume ratio of 100:3 to obtain solution E;

[0026] 5) Pipette the solution E into a Teflon-lined hydrothermal reaction kettle, and control the filling degree at 40%; seal the hydrothermal kettle and put it into the MDS-6 temperature-pressure dual-control microwave hydrothermal reactor The preparation reaction is carried out in the temperatur...

Embodiment 2

[0031] 1) The analytically pure cadmium acetate dihydrate (C 4 h 6 CdO 4 2H 2 O) added to deionized water, and kept stirring, configured as Cd 2+ A transparent solution A with a concentration of 0.4mol / L;

[0032] 2) The analytically pure thiourea (CH 4 N 2 S) added to deionized water, and kept stirring, configured as S 2- A transparent solution B with a concentration of 0.8mol / L;

[0033] 3) Slowly add an equal volume of solution B to solution A under strong stirring, and then ultrasonically disperse to obtain solution C;

[0034] 4) Prepare PVP solution D with a concentration of 0.2mol / L, and mix solution C and solution D at a volume ratio of 100:5 to obtain solution E;

[0035] 5) Pipette the solution E into a Teflon-lined hydrothermal reaction kettle, and control the filling degree at 60%; seal the hydrothermal kettle and put it into the MDS-6 temperature-pressure dual-control microwave hydrothermal reactor The preparation reaction is carried out in the temperatur...

Embodiment 3

[0038] 1) The analytically pure cadmium acetate dihydrate (C 4 h 6 CdO 4 2H 2 O) added to deionized water, and kept stirring, configured as Cd 2+ A transparent solution A with a concentration of 0.6mol / L;

[0039] 2) The analytically pure thiourea (CH 4 N 2 S) added to deionized water, and kept stirring, configured as S 2- A transparent solution B with a concentration of 0.9mol / L;

[0040] 3) Slowly add an equal volume of solution B to solution A under strong stirring, and then ultrasonically disperse to obtain solution C;

[0041] 4) Prepare PVP solution D with a concentration of 0.3mol / L, mix solution C and solution D at a volume ratio of 100:7 to obtain solution E;

[0042] 5) Pipette the solution E into a Teflon-lined hydrothermal reaction kettle, and control the filling degree at 70%; seal the hydrothermal kettle and put it into the MDS-6 temperature-pressure dual-control microwave hydrothermal reactor The preparation reaction is carried out in the temperature co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com