Preparation method of cadmium vanadate nanorods

A nanorod, cadmium vanadate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., achieves the effects of low preparation temperature, large specific surface area and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

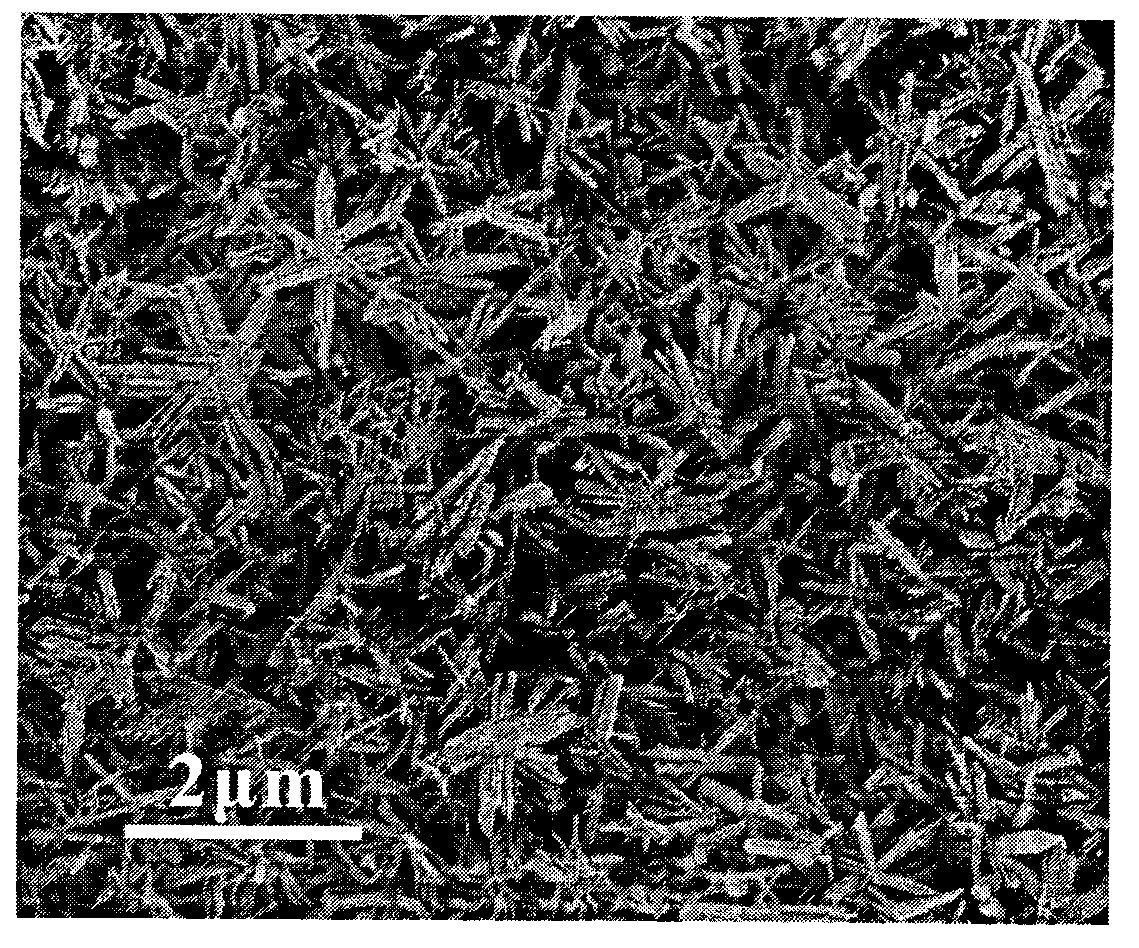

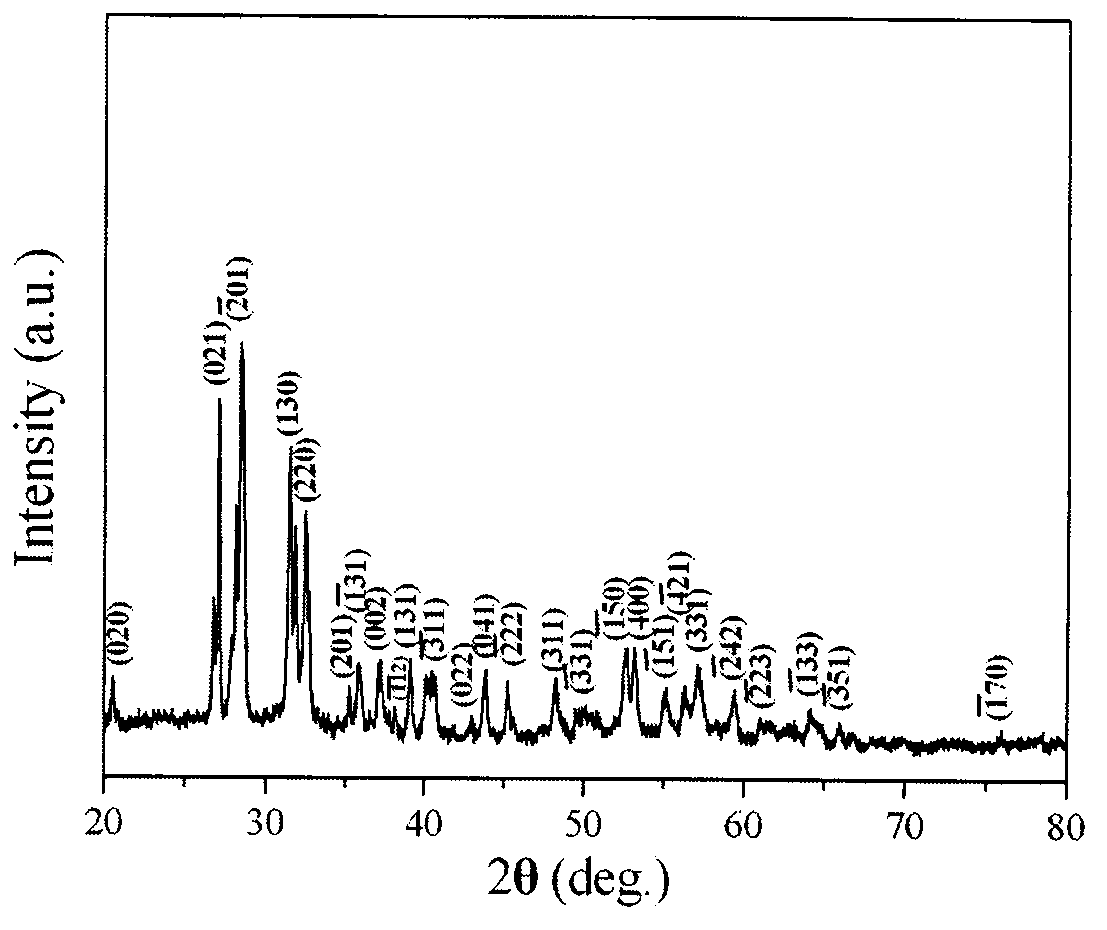

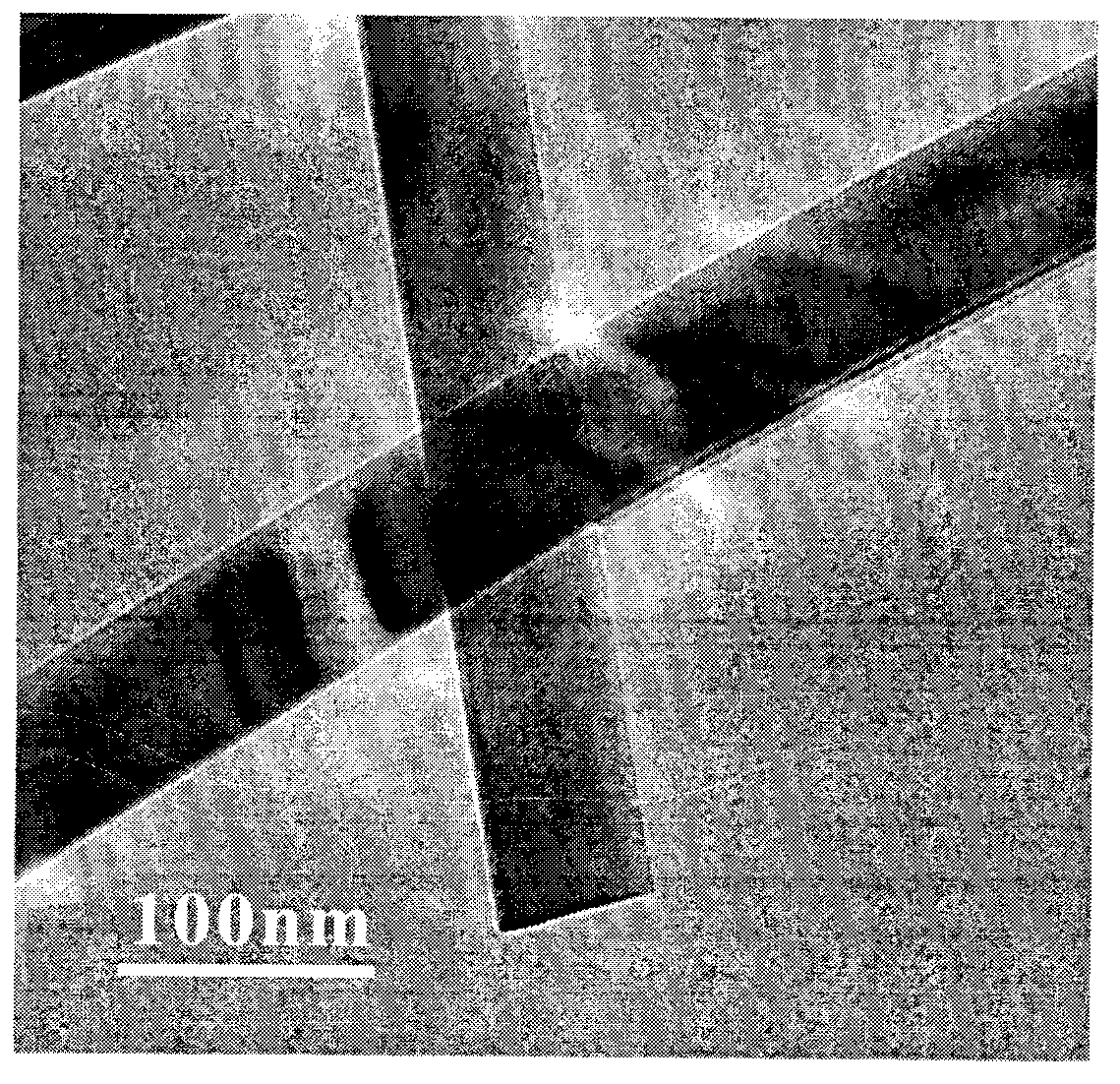

[0019] Embodiment 1: after cadmium acetate, sodium vanadate, PVP and water are evenly mixed, put into reaction container and seal, wherein the mol ratio of cadmium acetate and sodium vanadate is 1: 1, and cadmium acetate, sodium vanadate account for water solvent 10% by weight, PVP accounts for 8% by weight of water solvent. Then, the temperature was kept at 200° C. for 24 hours, and finally a cadmium vanadate nanorod fluffy white product with a length of about 2 μm and a diameter of about 70 nm was obtained.

Embodiment 2

[0020] Embodiment 2: Put cadmium acetate, sodium vanadate, PVP and water into the reaction vessel after uniform mixing and seal, wherein the mol ratio of cadmium acetate and sodium vanadate is 1: 1, cadmium acetate, sodium vanadate account for water solvent 7% by weight, PVP accounts for 6% by weight of water solvent. Then, the temperature was kept at 200° C. for 12 hours, and finally a cadmium vanadate nanorod fluffy white product with a length of about 2 μm and a diameter of about 70 nm was obtained.

Embodiment 3

[0021] Embodiment 3: after cadmium acetate, sodium vanadate, PVP and water are evenly mixed, put into reaction container and seal, wherein the mol ratio of cadmium acetate and sodium vanadate is 1: 1, and cadmium acetate, sodium vanadate account for water solvent 7% by weight, PVP accounts for 4% by weight of water solvent. Then, the temperature was kept at 180° C. for 12 hours, and finally a cadmium vanadate nanorod fluffy white product with a length of about 2 μm and a diameter of about 70 nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com