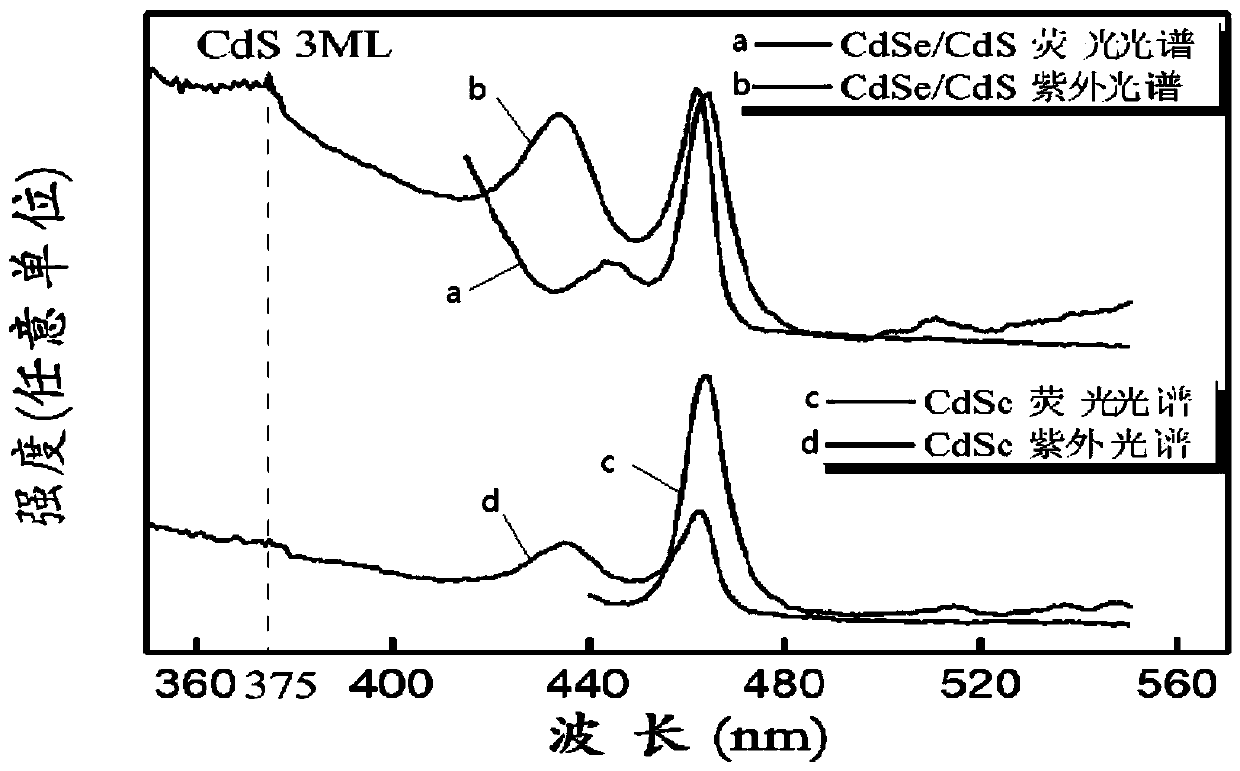

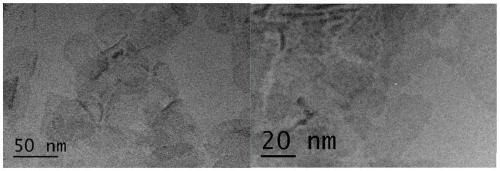

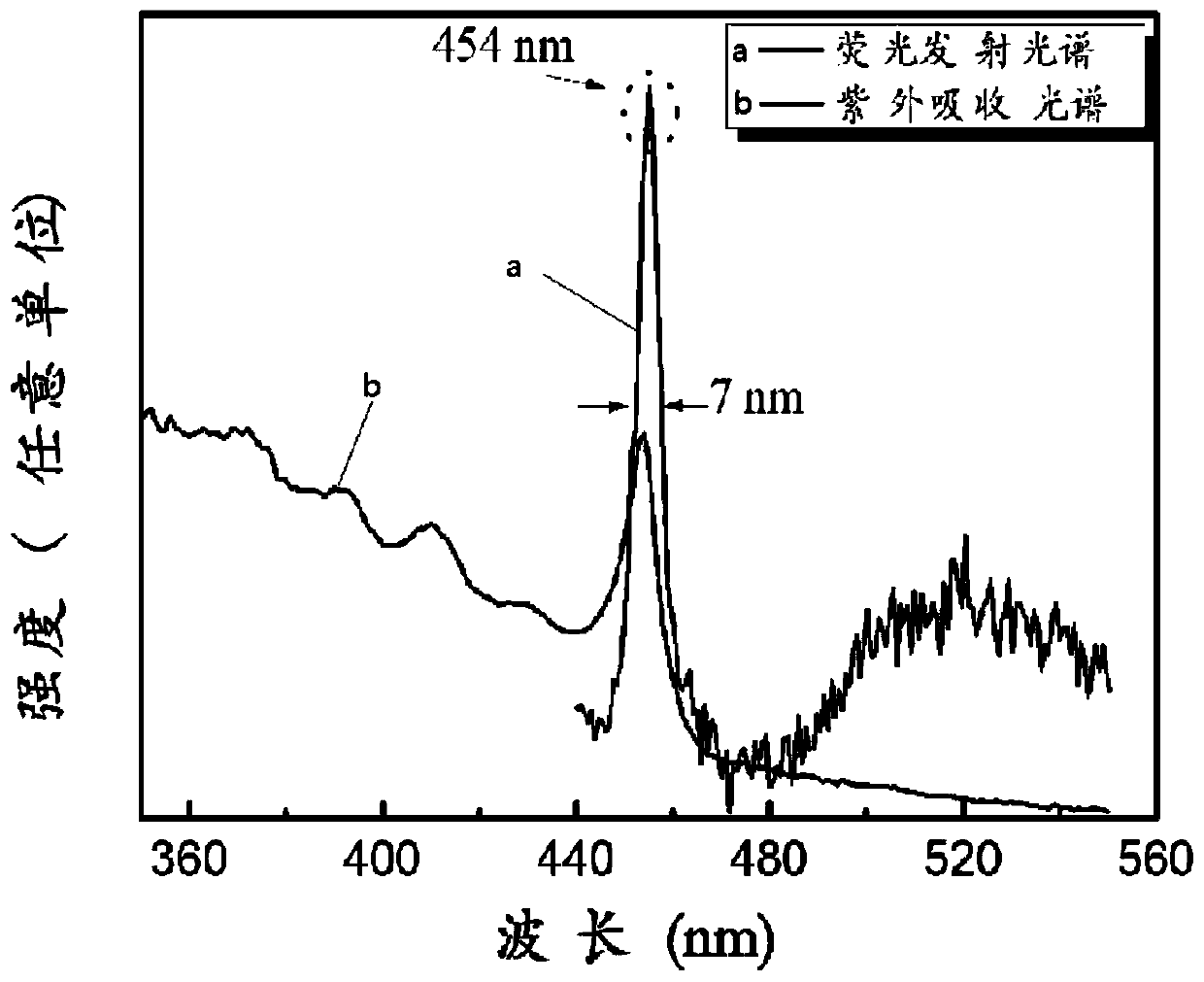

Preparation method of blue-light sphalerite CdSe/CdS nuclear crown structure nano sheet

A technology of nanosheets and sphalerite, applied in the field of nanomaterials for photoelectric display lighting, can solve the problems of CdSe/CdS core-cap structure nanosheet solution impurity, long reaction time, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment describes the synthesis method of sphalerite CdSe nanosheets disclosed in Chen Dongdong's doctoral thesis (Chemical Synthesis and Crystal Structure Characterization of Two-Dimensional Semiconductor Solution Nanocrystals), as a comparison of the method of the present invention.

[0021] 1. Preparation of core sphalerite CdSe nanosheets

[0022] The cadmium acetate dihydrate of 0.5mmol and the stearic acid (or oleic acid) of 0.3mmol and the ODE of 15ml are mixed in the three-necked flask of 25ml, after room temperature is led to argon and stirred for ten minutes, the temperature is raised to 230°C. After incubating at 230°C for 5 minutes, inject 2.5ml of Se-ODE into the flask, the temperature is still set at 230°C, use the absorption spectrum to track the reaction, and stop the reaction if necessary;

[0023] 2. Preparation of capping precursor

[0024] a) Stir 1.5mmol of Se powder and 15ml of ODE in a 25ml three-necked flask with argon gas in the mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com