Preparation method for 1D/2D vertical Cds/MoS2 catalyst used for hydrogen production

A technology of catalysts and mixtures, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve problems that are not conducive to photogenerated electron transport active sites, and achieve multiple reactive active sites, Promotes the separation of photogenerated electrons and holes and improves efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

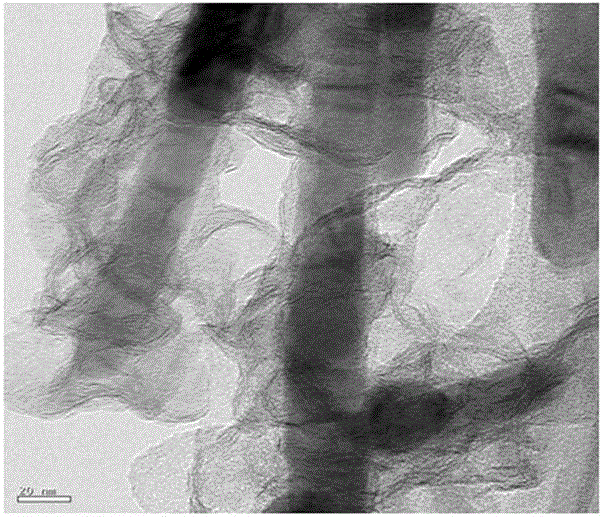

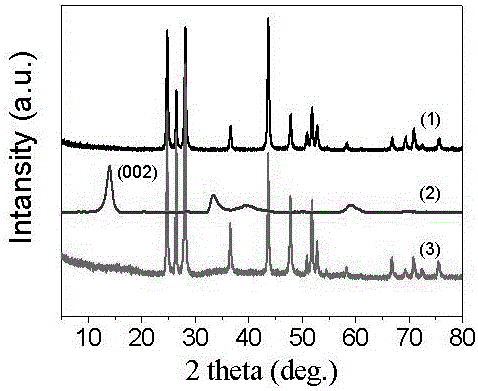

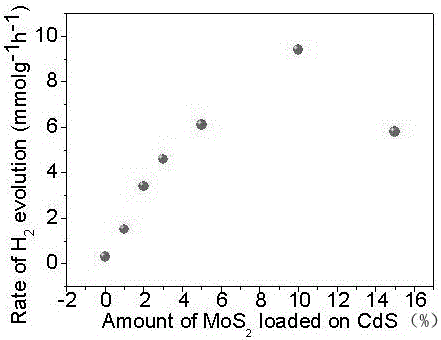

[0027] The 1D / 2D vertical CdS / MoS of this embodiment 2 The preparation method of hydrogen production catalyst, the steps are as follows:

[0028] (1) Dissolve 69 mg (0.3 mmol) of cadmium acetate and 16 mg (0.5 mmol) of sulfur powder in 10 mL of ethylenediamine and mix to obtain a yellow mixture A. The concentration of cadmium acetate is 0.03 mol / L, and the concentration of sulfur powder The concentration is 0.05 mol / L;

[0029] (2) Put the yellow mixture A in a hydrothermal reaction kettle and heat it at 180°C for 5 hours to obtain sample B;

[0030] (3) Sample B was naturally cooled to room temperature, centrifuged, washed twice with ethanol, and dried at 60°C for 12 hours to obtain CdS nanowires;

[0031] (4) Dissolve 46 mg (0.19 mmol) sodium molybdate and 94 mg (1.23 mmol) thiourea (Mo / S molar ratio is 1:6.5) in 20 mL, 0.05 mol / L glucose solution and mix Uniformly, mixture C is obtained;

[0032] (5) Add 0.27 g of CdS nanowires prepared in step (3) to the mixture C in ste...

Embodiment 2

[0035] The 1D / 2D vertical CdS / MoS of this embodiment 2 The preparation method of hydrogen production catalyst, the steps are as follows:

[0036] (1) Dissolve 138 mg (0.6 mmol) of cadmium acetate and 32 mg (1.0 mmol) of sulfur powder in 20 mL of ethylenediamine and mix to obtain a yellow mixture A. The concentration of cadmium acetate is 0.03 mol / L, and the concentration of sulfur powder The concentration is 0.05 mol / L;

[0037] (2) Put the yellow mixture A in a hydrothermal reactor and heat it at 220°C for 3 hours to obtain sample B;

[0038] (3) Sample B was naturally cooled to room temperature, centrifuged, washed twice with ethanol, and dried at 80°C for 10 hours to obtain CdS nanowires;

[0039] (4) Dissolve 46 mg (0.19 mmol) sodium molybdate and 92 mg (1.23 mmol) thioacetamide (the molar ratio of Mo / S is 1:6.5) in 20 mL, 0.05 mol / L glucose solution and mixed uniformly to obtain mixture C;

[0040] (5) Add 2.97 g of CdS nanowires prepared in step (3) to the mixture C ...

Embodiment 3

[0043] The 1D / 2D vertical CdS / MoS of this embodiment 2 The preparation method of hydrogen production catalyst, the steps are as follows:

[0044] (1) Dissolve 207 mg (0.9 mmol) of cadmium acetate and 48 mg (1.5 mmol) of sulfur powder in 30 mL of ethylenediamine and mix to obtain a yellow mixture A. The concentration of cadmium acetate is 0.03 mol / L, and the concentration of sulfur powder The concentration is 0.05 mol / L;

[0045] (2) Put the yellow mixture A in a hydrothermal reactor and heat it at 200°C for 4 hours to obtain sample B;

[0046] (3) Sample B was naturally cooled to room temperature, centrifuged, washed twice with ethanol, and dried at 70°C for 11 hours to obtain CdS nanowires;

[0047] (4) Dissolve 37 mg (0.19 mmol) ammonium molybdate and 94 mg (1.23 mmol) thiourea (Mo / S molar ratio is 1:6.5) in 20 mL, 0.05 mol / L glucose solution and mix Uniformly, mixture C is obtained;

[0048] (5) Add 1.47 g of CdS nanowires prepared in step (3) to the mixture C in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com