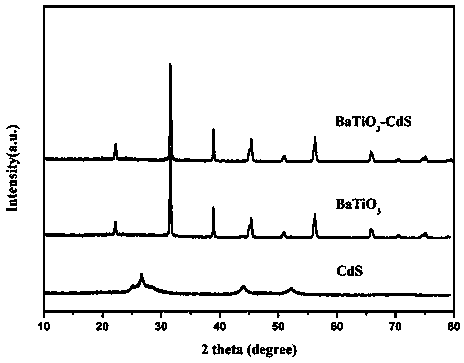

BaTiO3-CdS nanometer composite photocatalyst and preparation method thereof

A nano-composite, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., to reduce the recombination rate, improve the photocatalytic activity, and improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 BaTiO 3 Precursor preparation

[0031] Measure 5 mL of ethanol and 8.508 g of tetrabutyl titanate, add 5 mL of deionized water under continuous magnetic stirring to obtain solution A, prepare 10 mL of 3.75 M barium hydroxide solution B, add 4 mL of ammonia water, then slowly add solution B to solution A, and react for 30 min in an oil bath at 80°C to prepare BaTiO 3 Precursor C.

Embodiment 2

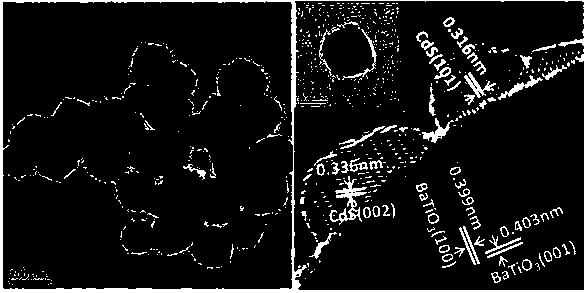

[0032] Example 2 BaTiO 3 Preparation of nanospheres

[0033] Add the solution C prepared in Example 1 into a polytetrafluoroethylene reactor, add deionized water to 60% of the volume of the reactor, and stir magnetically until the mixture is evenly dispersed. After reacting at 200°C for 24 hours, the obtained product was naturally cooled to room temperature, washed several times with deionized water and ethanol respectively, the precipitate was collected by centrifugation, and dried in vacuum to obtain BaTiO 3 nanospheres.

Embodiment 3

[0034] Example 3 BaTiO 3 - Preparation of CdS composites

[0035] With the BaTiO obtained in embodiment 2 3 The nanospheres were ultrasonically dispersed in deionized water, and 148 mg of cadmium acetate dihydrate was added to disperse evenly, followed by the addition of 80 mg of thiourea, and the reaction was carried out in an oil bath at 80°C for 30 min. The solid product was collected by suction filtration, washed several times with deionized water and ethanol respectively, and dried in vacuum to obtain the BaTiO 3 -CdS composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com