Method for preparing CdS/MIL-53(Fe) visible-light-induced photocatalyst

A catalyst, visible light technology, applied in the field of photocatalytic material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of this embodiment are as follows:

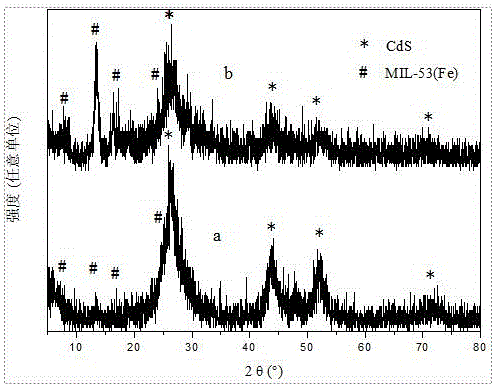

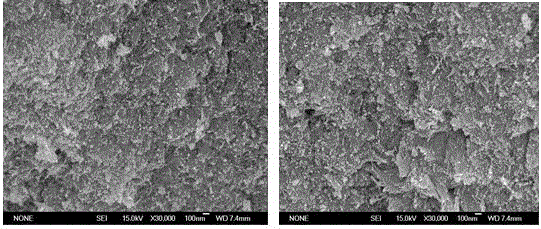

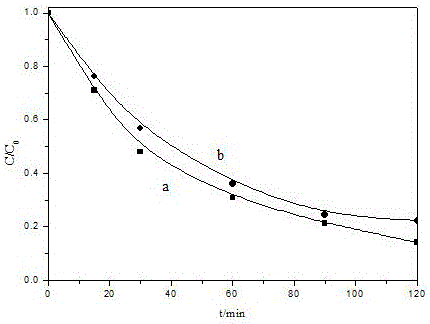

[0035] In this embodiment, the preparation method of CdS / MIL-53(Fe) visible light catalyst is to use ferric chloride, terephthalic acid and N,N-dimethylformamide as raw materials, and adopt the solvothermal method Preparation of MIL-53 (Fe) material; then using the obtained MIL-53 (Fe) and cadmium acetate, thioacetamide, polyvinylpyrrolidone and ethylene glycol as raw materials, the solvothermal method was used to prepare CdS / MIL-53 (Fe ) composite material. Its technological process is: weigh the FeCl of 10 mmol 3 ·6H 2 O and 10 mmol of terephthalic acid were dissolved in 50 mL of N,N-dimethylformamide reagent, and stirred continuously at room temperature to fully dissolve ferric chloride and terephthalic acid; the resulting mixture was Move it into a 100 mL reaction kettle, put the reaction kettle in an oven at 150°C, and react for 12 hours; after cooling to room temperature, centrifuge, wash with double disti...

Embodiment 2

[0039] The concrete steps of this embodiment are as follows:

[0040] In this embodiment, the preparation method of CdS / MIL-53(Fe) visible light catalyst is to use ferric chloride, terephthalic acid and N,N-dimethylformamide as raw materials, and adopt the solvothermal method Preparation of MIL-53 (Fe) material; then using the obtained MIL-53 (Fe) and cadmium acetate, thioacetamide, polyvinylpyrrolidone and ethylene glycol as raw materials, the solvothermal method was used to prepare CdS / MIL-53 (Fe ) composite material. Its technological process is: weigh the FeCl of 10 mmol 3 ·6H 2 O and 10 mmol of terephthalic acid were dissolved in 50 mL of N,N-dimethylformamide reagent, and stirred continuously at room temperature to fully dissolve ferric chloride and terephthalic acid; the resulting mixture was Move it into a 100 mL reaction kettle, put the reaction kettle in an oven at 150°C, and react for 12 hours; after cooling to room temperature, centrifuge, wash with double disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com