Tantalum titanate cadmium sulphide platinum-carried laminated composite catalyst and its preparation method

A platinum catalyst and cadmium sulfide technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor air oxidation resistance, intensified photocorrosion, and limited applications, etc. Improved photocorrosion ability, increased crystallinity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

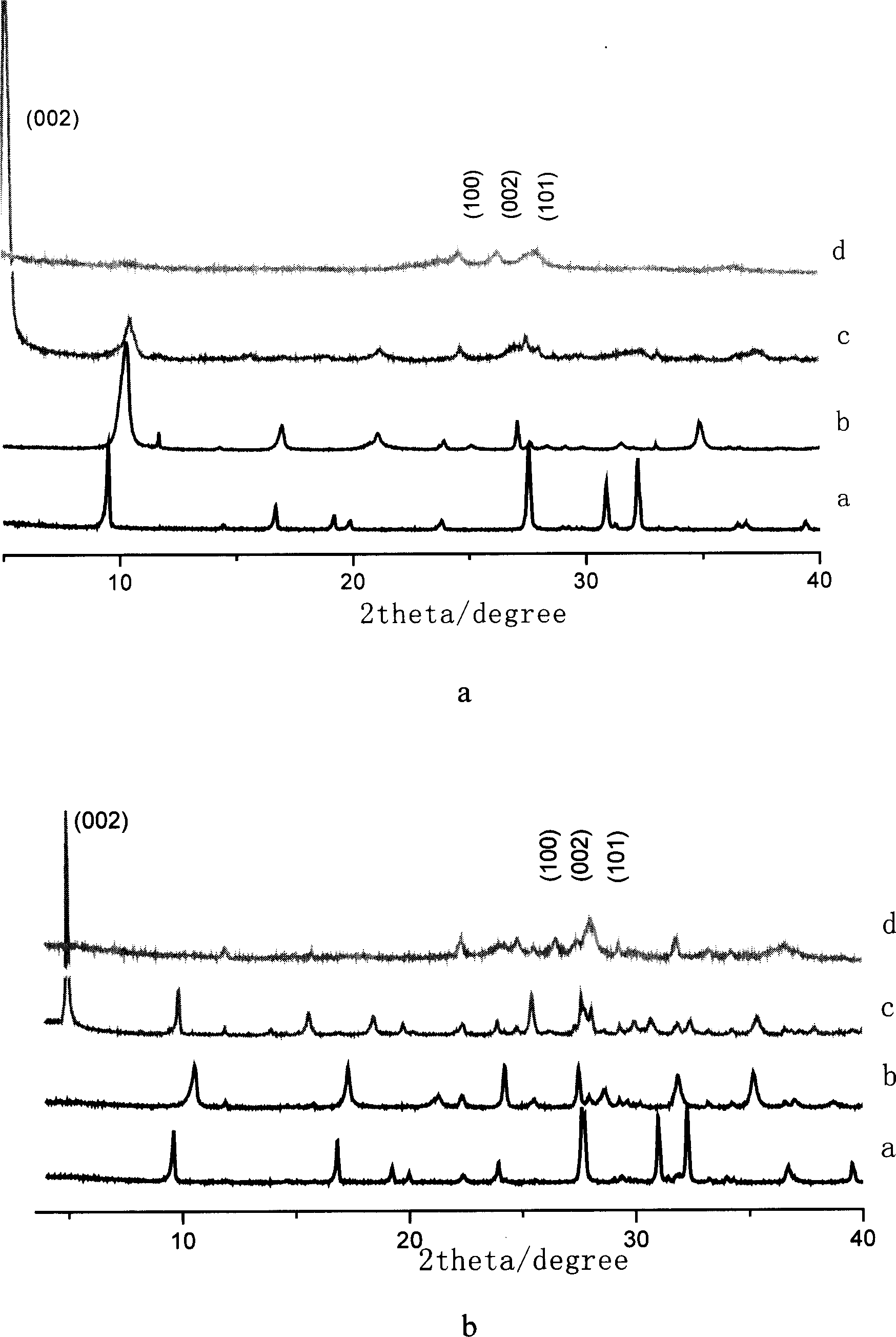

[0049] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mixed according to the stoichiometric ratio, wherein an excess of K is added 2 CO 3 , whose molar weight is 10%, calcined at 700°C for 1 hour, ground for 1-2 hours and then calcined at 1000°C for 12 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0050] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 2mol / L, stir at room temperature for 2 days, wash the product with deionized water after ion exchange, until the pH of the washing residue is 5, and dry it at 80°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

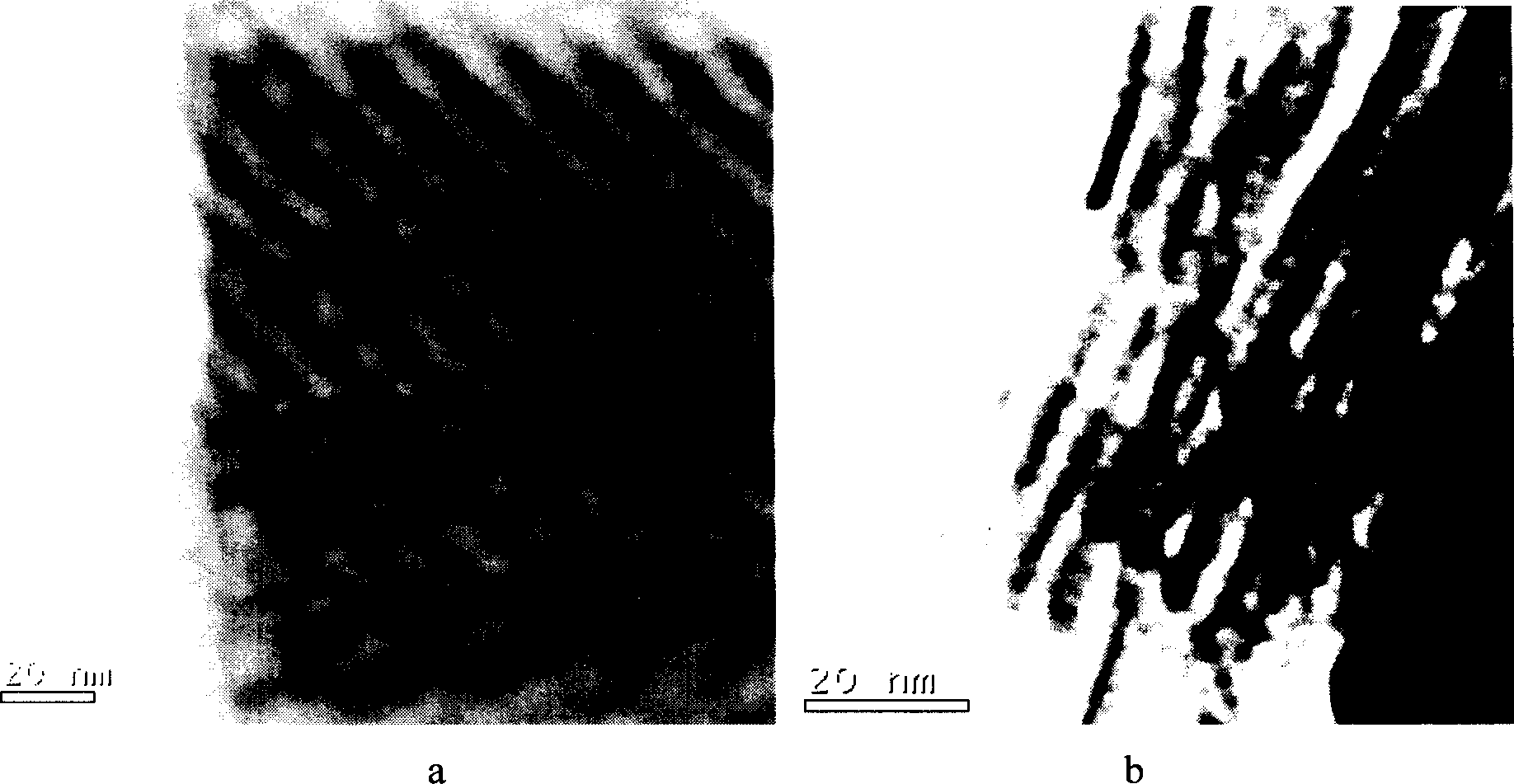

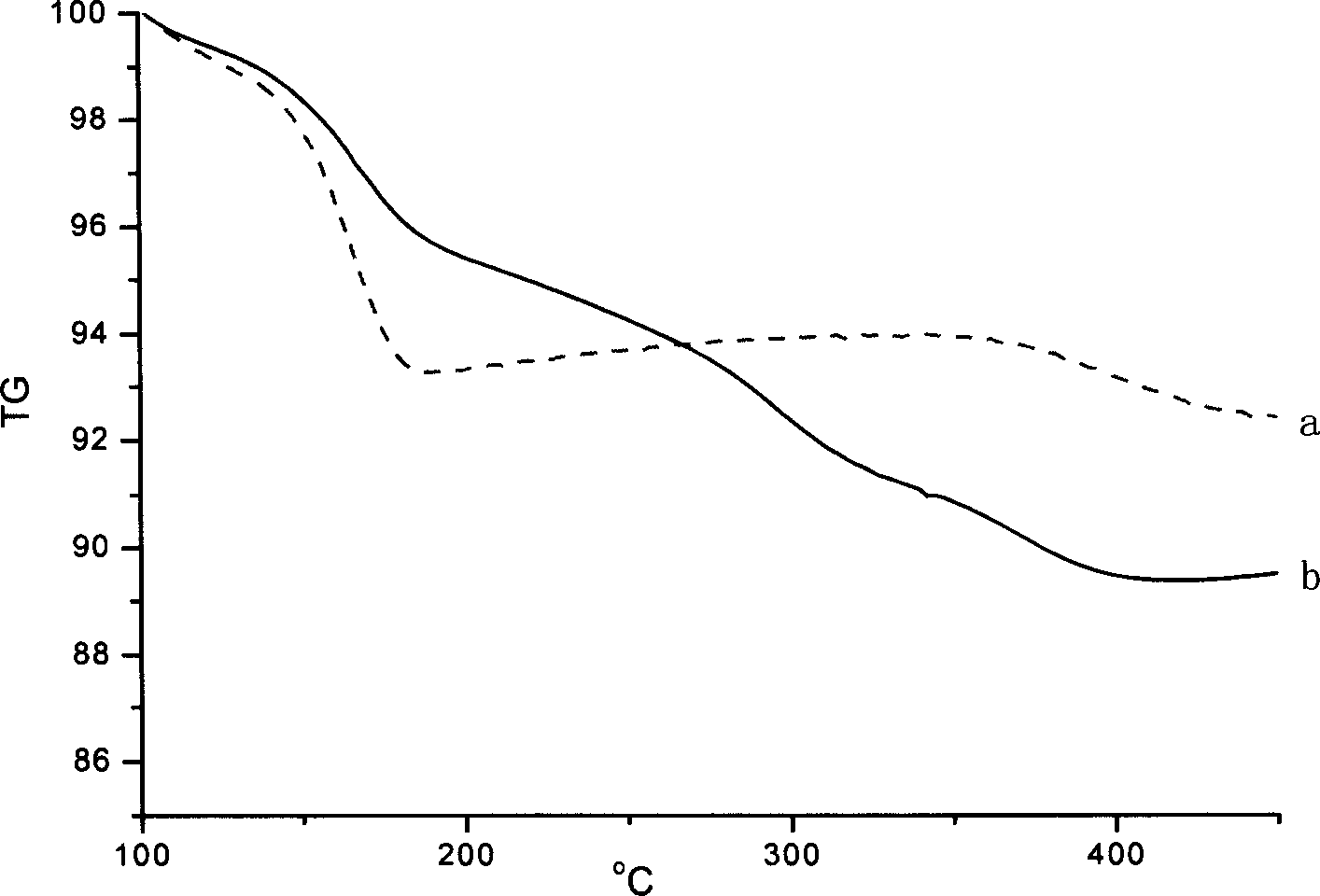

[0051] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml of propylamine aqueous solution, volume ratio 1:1, reflux and stir at 40°C for 2 days to obtain propylamine pillars of layered matrix; place 5g of propylamine pillars of layered matrix in 250ml saturated cadmium acetate solution, 50°C Stir at -80...

Embodiment 2

[0055] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mix according to the stoichiometric ratio, wherein an excess of potassium carbonate K is added 2 CO 3 , whose molar weight is 15%, calcined at 800°C for 1 hour, ground for 1 hour and then calcined at 1100°C for 24 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0056] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 4mol / L, stir at room temperature for 2 days, wash the obtained product with deionized water after ion exchange, until the pH of the washing residue is 6, and dry at 90°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

[0057] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml of propylamine aqueous solution, volume ratio 1:1, reflux and stir at 50°C for 2 days to obtain propylamine pillars of layered matrix; place 5g of propylamine pillars of layered matrix in 250ml saturated cadmium acetate soluti...

Embodiment 3

[0061] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mixed according to the stoichiometric ratio, wherein an excess of K is added 2 CO 3 , whose molar weight is 25%, calcined at 900°C for 2 hours, ground for 2 hours and then calcined at 1150°C for 24 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0062] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 5mol / L, stir at room temperature for 3 days, wash the product with deionized water after ion exchange, until the pH of the washing residue is 7, and dry at 100°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

[0063] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml propylamine aqueous solution, volume ratio 1: 1, reflux and stir at 60°C for 3 days to obtain the propylamine pillars of the layered matrix; place 5g of the propylamine pillars of the layered matrix in 250ml saturated cadmium acetate solution, 70°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com