A kind of carbon dots/carbon nitride/titanium dioxide composite material and its preparation method and application

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve problems such as ineffective effects, achieve enhanced migration, enhanced photocatalytic activity, and improved photocatalytic hydrogen production active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

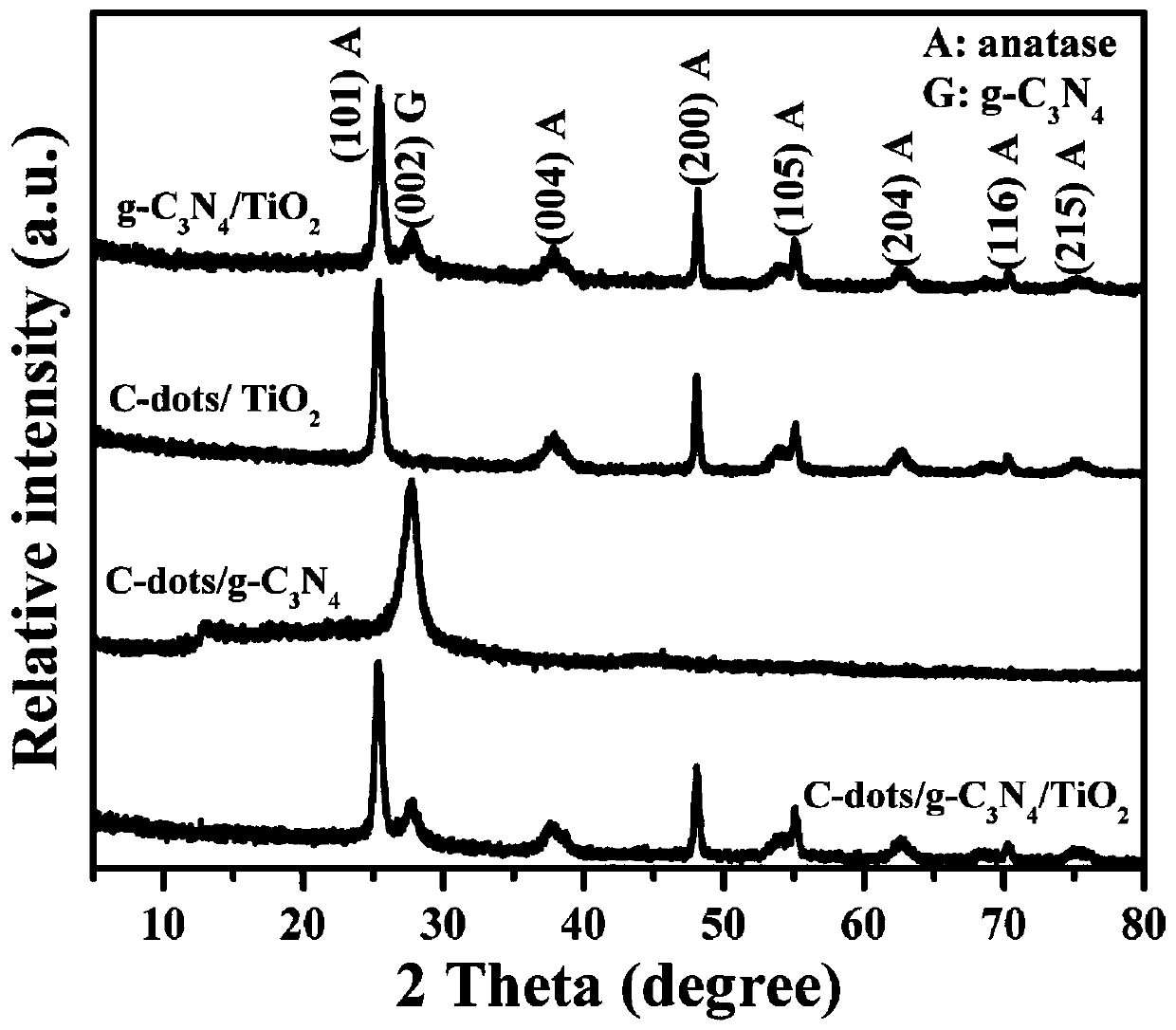

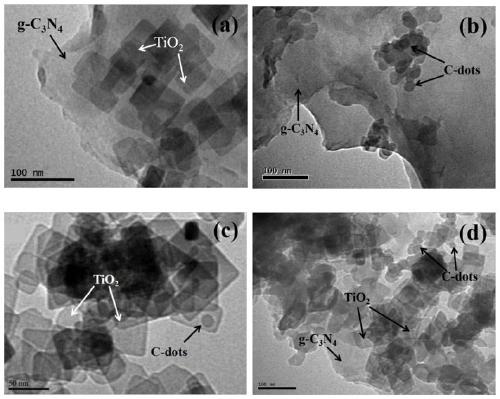

[0029] A carbon dot / carbon nitride / titanium dioxide (C-dots / g-C 3 N 4 / TiO 2 ) The preparation method of composite material, comprises the steps:

[0030] (1) Titanium dioxide (TiO 2 ) Preparation of nanosheets: First, add 25ml tetrabutyltitanate (TBT) and 3ml hydrofluoric acid into a polytetrafluoroethylene reactor, stir and mix evenly, place the reactor in an oven and heat to 180°C, The holding time is 24 hours. After the reaction, the reactor is cooled to room temperature, and then the product obtained is washed with 1M sodium hydroxide to neutrality, then washed with water and ethanol three times, and finally the product is dried to obtain titanium dioxide (TiO 2 )Nanosheets;

[0031] (2) Preparation of carbon nitride (g-C 3 N 4 ): First, weigh 1.2g of urea and 2.5g of melamine in a molar ratio of 1:1, grind and mix them evenly in a mortar, then transfer the mixture into a semi-closed crucible, and heat it in a muffle furnace to 550°C for Calcining, the holding time...

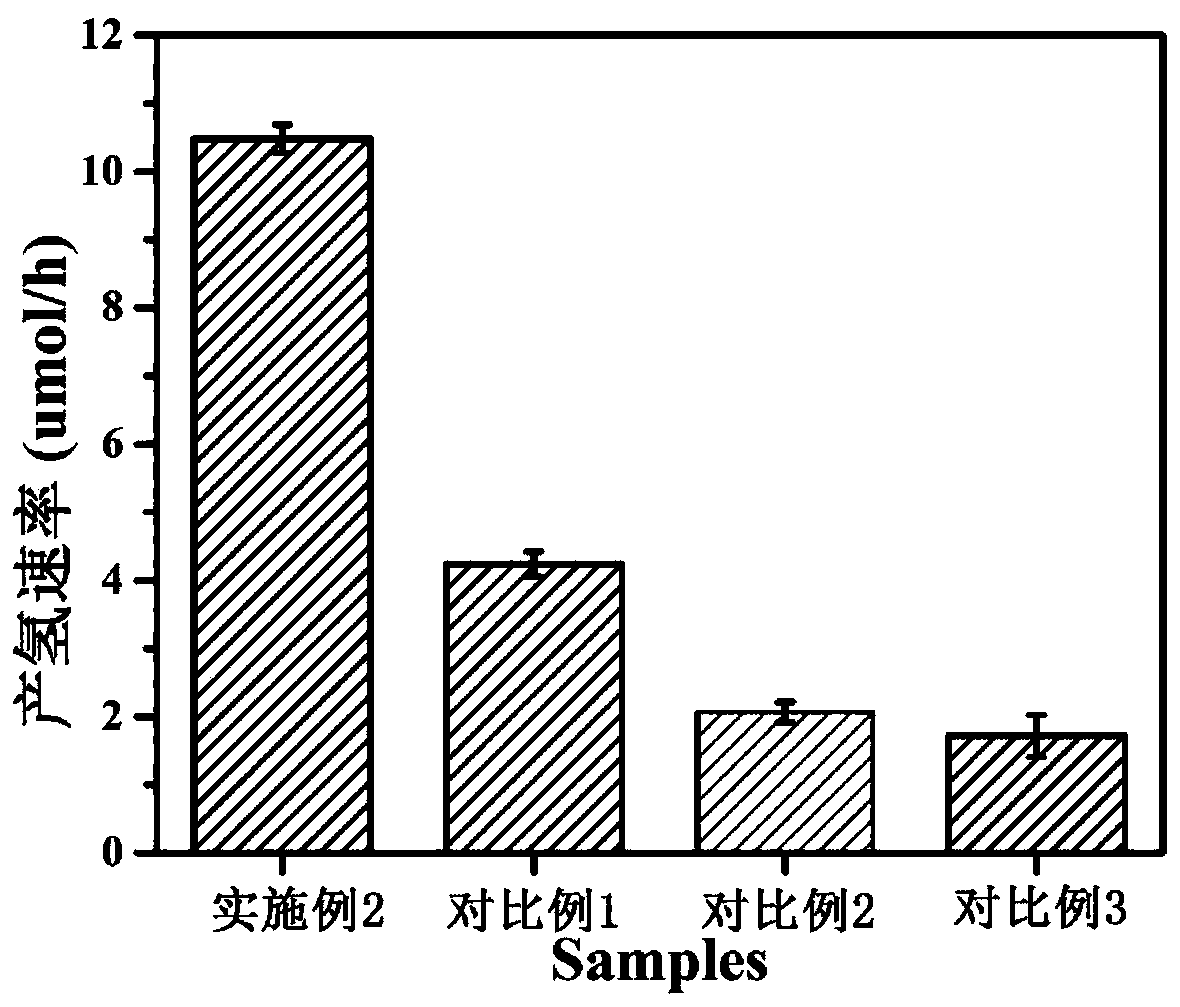

Embodiment 2

[0035] A carbon dot / carbon nitride / titanium dioxide (C-dots / g-C 3 N 4 / TiO 2 ) The preparation method of composite material, comprises the steps:

[0036] (1) Titanium dioxide (TiO 2 ) Preparation of nanosheets: First, add 25ml tetrabutyltitanate (TBT) and 3ml hydrofluoric acid into a polytetrafluoroethylene reactor, stir and mix evenly, place the reactor in an oven and heat to 180°C, The holding time is 24 hours. After the reaction, the reactor is cooled to room temperature, and then the product obtained is washed with 1M sodium hydroxide to neutrality, then washed with water and ethanol three times, and finally the product is dried to obtain titanium dioxide (TiO 2 )Nanosheets;

[0037] (2) Preparation of carbon nitride (g-C 3 N 4 ): First, weigh 1.2g of urea and 2.5g of melamine in a molar ratio of 1:1, grind and mix them evenly in a mortar, then transfer the mixture into a semi-closed crucible, and heat it in a muffle furnace to 550°C for Calcining, the holding time...

Embodiment 3

[0041] A carbon dot / carbon nitride / titanium dioxide (C-dots / g-C 3 N 4 / TiO 2 ) The preparation method of composite material, comprises the steps:

[0042] (1) Titanium dioxide (TiO 2 ) Preparation of nanosheets: First, add 25ml tetrabutyltitanate (TBT) and 3ml hydrofluoric acid into a polytetrafluoroethylene reactor, stir and mix evenly, place the reactor in an oven and heat to 180°C, The holding time is 24 hours. After the reaction, the reactor is cooled to room temperature, and then the product obtained is washed with 1M sodium hydroxide to neutrality, then washed with water and ethanol three times, and finally the product is dried to obtain titanium dioxide (TiO 2 )Nanosheets;

[0043] (2) Preparation of carbon nitride (g-C 3 N 4 ): First, weigh 1.2g of urea and 2.5g of melamine in a molar ratio of 1:1, grind and mix them evenly in a mortar, then transfer the mixture into a semi-closed crucible, and heat it in a muffle furnace to 550°C for Calcining, the holding time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com