Titanium dioxide ultraviolet light photocatalyst supported by nickel carbonate and preparation method thereof

A technology of titanium dioxide and photocatalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the cost of raw materials, scarcity, and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

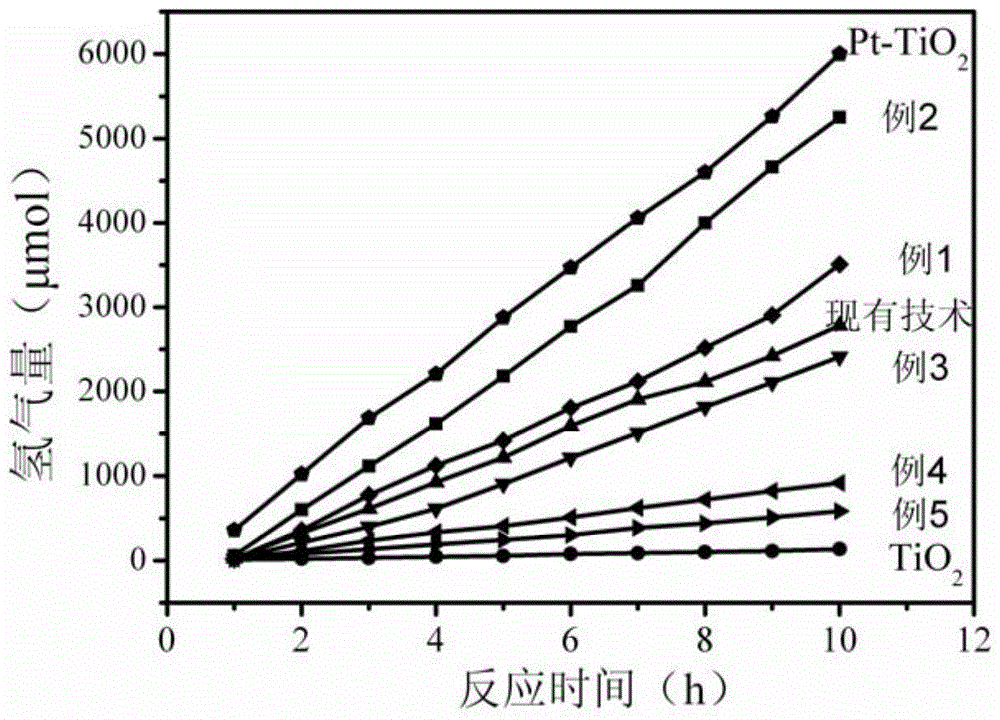

Embodiment 1

[0023] A preparation method of titanium dioxide ultraviolet light photocatalyst supported by nickel carbonate, comprising the following steps:

[0024] 1) Take by weighing 1g of titanium dioxide, 0.2g of sodium carbonate and 0.002g of nickel nitrate according to the above weight fraction ratio, and set aside;

[0025] 2) dissolving the sodium carbonate obtained in step 1) in water to obtain an aqueous sodium carbonate solution with a molar concentration of 0.1 to 1.0 mmol / L;

[0026] 3) dispersing titanium dioxide into the aqueous sodium carbonate solution obtained in step 2) to obtain a suspension;

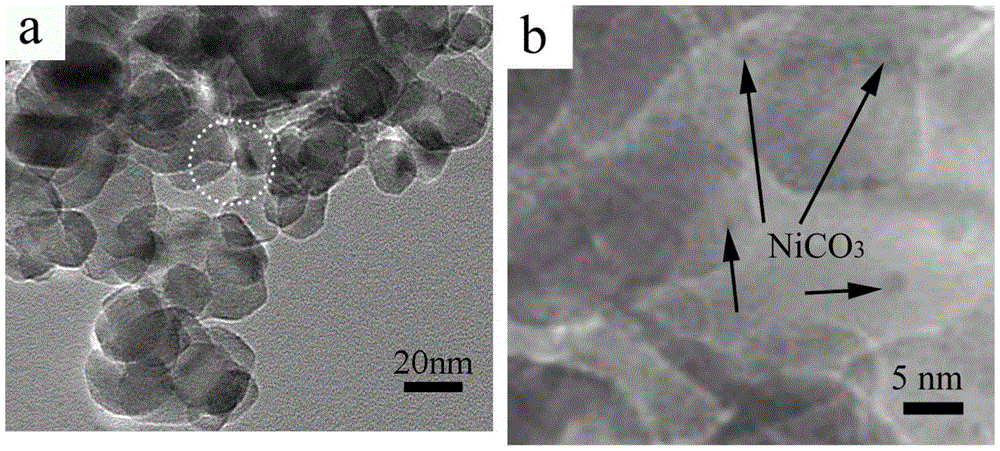

[0027] 4) Slowly add nickel nitrate to the suspension obtained in step 3), stir evenly, wash and stand still, filter with filter paper, and vacuum dry at a temperature of 60-100°C for 4-8 hours to obtain titanium dioxide supported by nickel carbonate An ultraviolet light photocatalyst; wherein, the nickel carbonate is supported on the surface of titanium dioxide, and the weight ...

Embodiment 2

[0029] The preparation method of this embodiment and embodiment 1 is basically the same, the difference is:

[0030] Nickel carbonate-supported titanium dioxide ultraviolet light photocatalyst 2, said photocatalyst comprises 1 part of titanium dioxide, 0.5 part of potassium carbonate, and 0.01 part of nickel sulfate in terms of the weight ratio of raw materials. Nickel carbonate accounts for 0.9% by weight of the photocatalyst.

Embodiment 3

[0032] The preparation method of this embodiment and embodiment 1 is basically the same, the difference is:

[0033] Nickel carbonate-supported titanium dioxide ultraviolet photocatalyst 3, the photocatalyst includes 1 part of titanium dioxide, 0.3 part of sodium carbonate, and 0.015 part of nickel nitrate in terms of the weight ratio of raw materials. Nickel carbonate accounts for 1.5% by weight of the photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com