Pretreatment system and method for raw anaerobic fermentation material

An anaerobic fermentation and pretreatment technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of scum and sand settling that are difficult to remove, achieve simple and easy treatment, expand the utilization of biogas, and improve the efficiency of nutrients The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

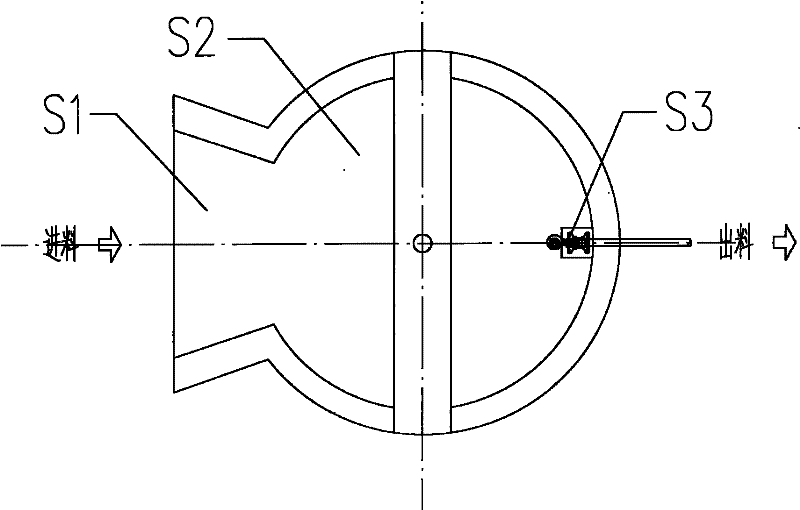

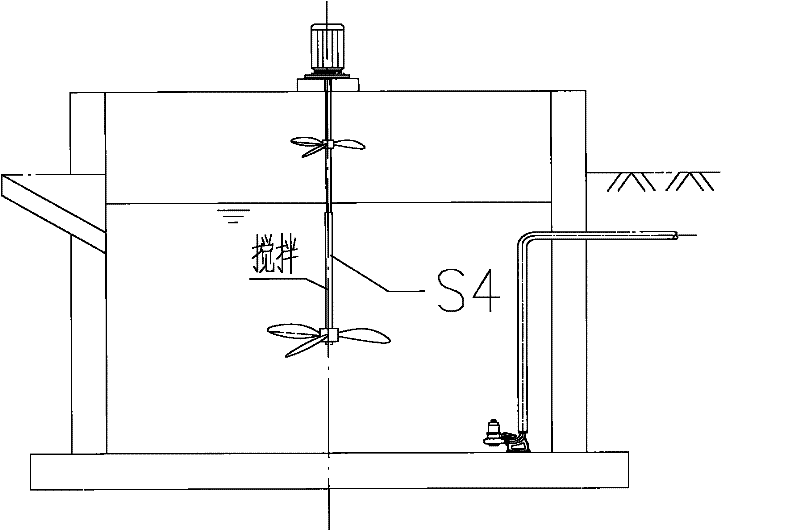

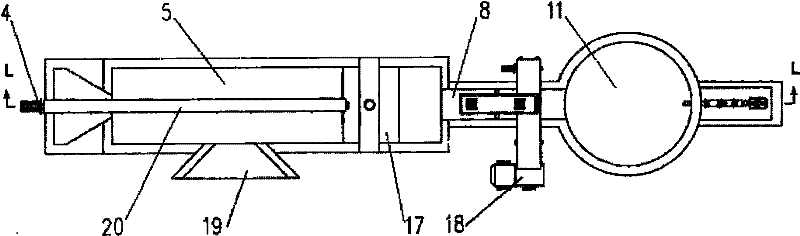

[0047] figure 2 It is a schematic structural view of the anaerobic fermentation raw material pretreatment system of the present invention, image 3 for figure 2 The section view of the anaerobic fermentation raw material pretreatment system shown along the line L-L.

[0048] Such as figure 2 As shown, the anaerobic fermentation raw material pretreatment system of the present invention includes: a pretreatment tank 5, which is equipped with anaerobic fermentation raw material, and in the pretreatment tank 5, the anaerobic fermentation raw material is diluted, stirred and settled and stratified, The anaerobic fermentation raw material is separated into the scum of the upper layer, the nutrients of the middle layer and the grit of the lower layer; the grid channel 8 is communicated with the pretreatment pool 5, and the pretreatment pool 5 is locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com