Method for efficiently producing marsh gas by performing moderate-temperature anaerobic dry fermentation on agricultural waste

A technology of agricultural waste and thermo-anaerobic drying is applied in the field of high-efficiency biogas production by mid-temperature anaerobic dry fermentation of agricultural waste, which can solve problems such as excessive acidification, increase gas production rate, improve system buffer performance, and practice energy saving and emission reduction. The effect of meaning and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

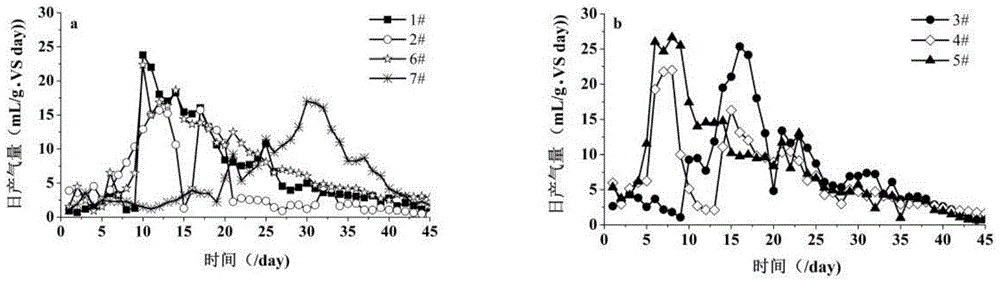

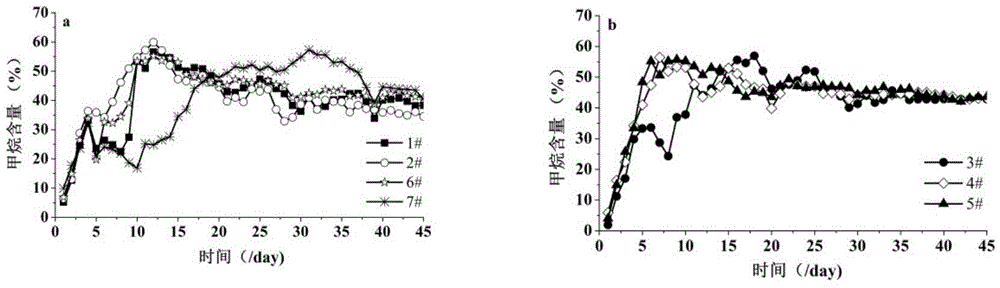

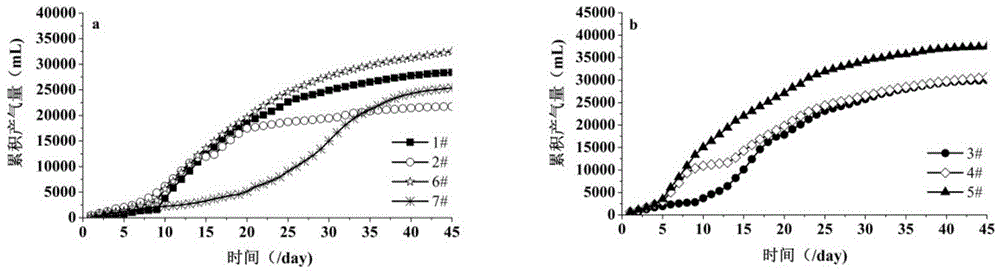

[0050] Example 1. Livestock and poultry manure, crop stalks and vegetable wastes were subjected to combined anaerobic mesothermal batch dry fermentation

[0051] 1. Anaerobic fermentation method: mix livestock and poultry manure, crop stalks and vegetable waste to obtain raw materials; put the raw materials and inoculum in a 1L anaerobic fermentation bottle, and feed nitrogen into the anaerobic fermentation bottle 5min to exhaust the air in the headspace of the reactor to ensure an anaerobic environment for the reaction. Then it was placed in a constant temperature incubator at (35±1)°C for mesophilic anaerobic batch fermentation test, with 7 treatments in total. The conditions of each treatment are shown in Table 1, and the physical and chemical properties of the raw materials are shown in Table 2. In the following 7 groups of experiments, the mass of volatile solids (volatile solid, VS) in the total mixture is 122g / L~124g / L within range.

[0052] Table 1 Conditions of 7 tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com