Double-chamber anaerobic methane secondary fermentation device

A secondary fermentation, dual-chamber technology, used in gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of low construction efficiency, scattered buildings, poor thermal insulation effect, etc., to achieve convenient management and maintenance, reduce Project cost and effect of prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

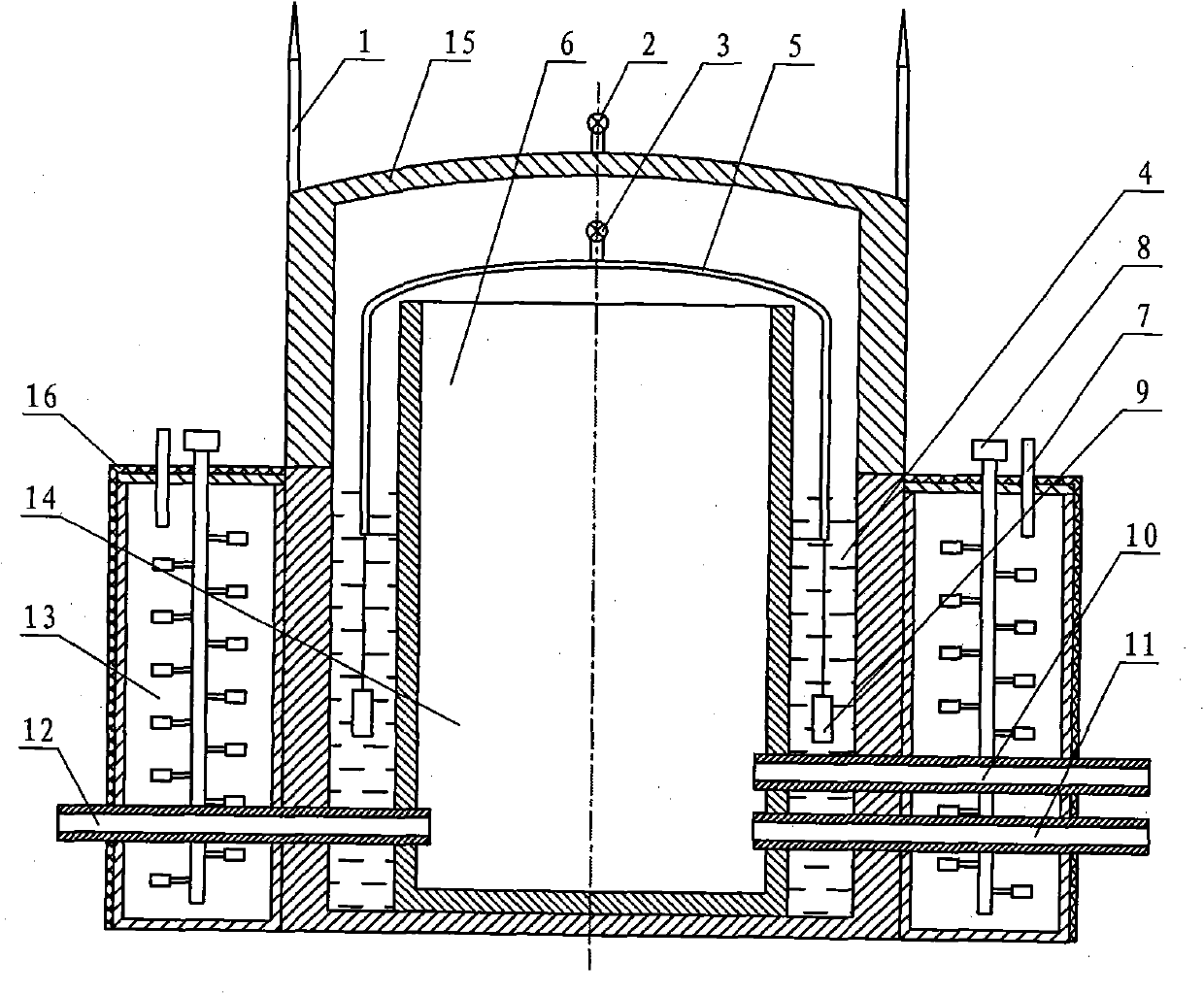

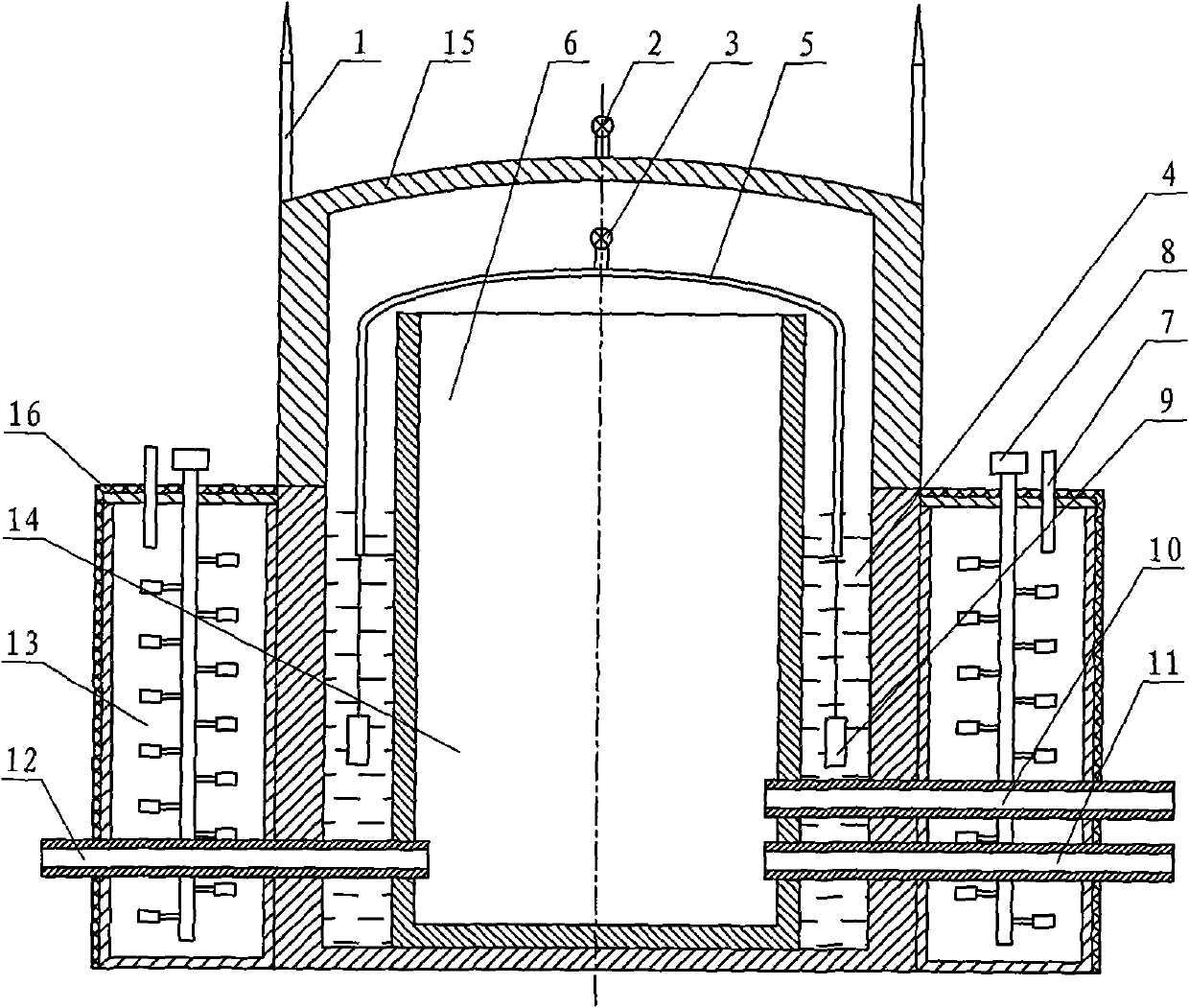

[0017] As shown in the figure: a dual-chamber anaerobic biogas secondary fermentation device is composed of a primary fermentation chamber and a secondary fermentation chamber. The primary fermentation chamber 13 is provided with a feed inlet 7 and an agitator 8 is installed inside. The exterior of the secondary fermentation chamber 14 is equipped with a shell 15, which can be used as a biogas slurry storage room, which reduces the construction footprint of the biogas slurry storage tank. There is a water layer 4 between the shell and the secondary fermentation chamber. The fermentation room is covered with a gas storage hood 5, and the bottom of the gas storage hood is equipped with a counterweight 9, which is placed in water, so that the air supply pressure can be balanced and the gas can be sent to the gas point without any power, so that the storage An air storage chamber 6 is formed on the upper part of the air cover, and a safety valve 3 is installed on the air storage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com