Process for producing biogas by two-stage anaerobic fermentation of crop stalk or livestock excrement

A technology for crop straw and livestock and poultry manure, which is applied in the directions of fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of inoculum of crop straws being difficult to obtain, increase processing costs, and low gas production rate, and achieve the promotion of resource utilization. , Low cost input, the effect of improving gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The process for producing biogas by two-stage anaerobic fermentation of crop straw and livestock and poultry manure in the laboratory is characterized in that it includes the following steps:

[0027] (1) Ingredients

[0028] 10 grams of corn stalks, 15 grams of dry chicken manure, 15 grams of dry cow manure, 30 grams of water;

[0029] (2) Prepare and mix materials

[0030] Prepare 10 grams of corn stalks crushed to a particle size of 2 mm, 30 grams of a mixture of dry chicken manure and dry cow manure, and mix them uniformly with 30 grams of water;

[0031] (3) Acidification stage reaction

[0032] Add 70 grams of the above-mentioned mixed materials into a 500-milliliter conical flask every day, and carry out acidification reaction at a constant temperature of 25°C in a water bath, adjust the pH value between 4.6-5.0, and generate an acidification section after the residence time is 48 hours. material, start to discharge 70 g / day continuously;

[0033] (4) Acidifi...

Embodiment 2

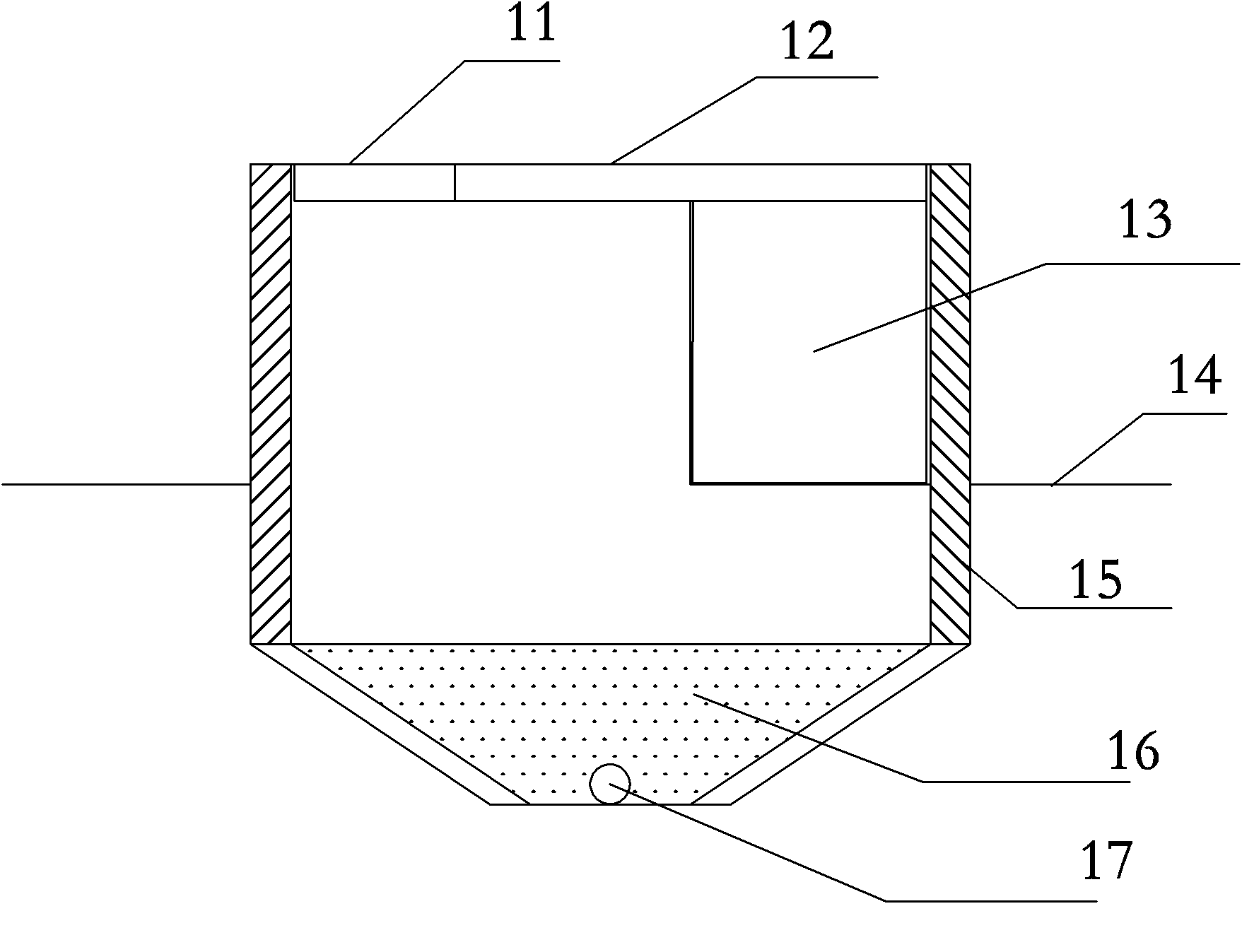

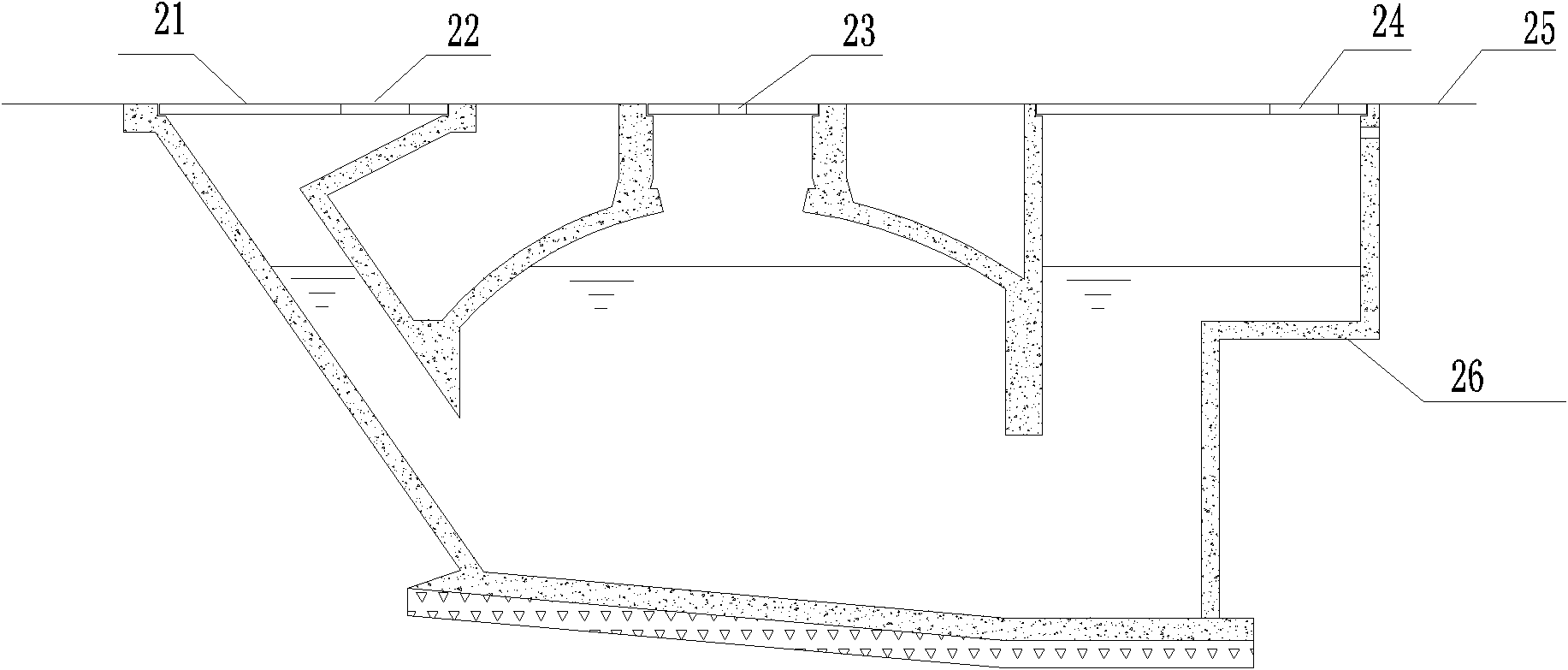

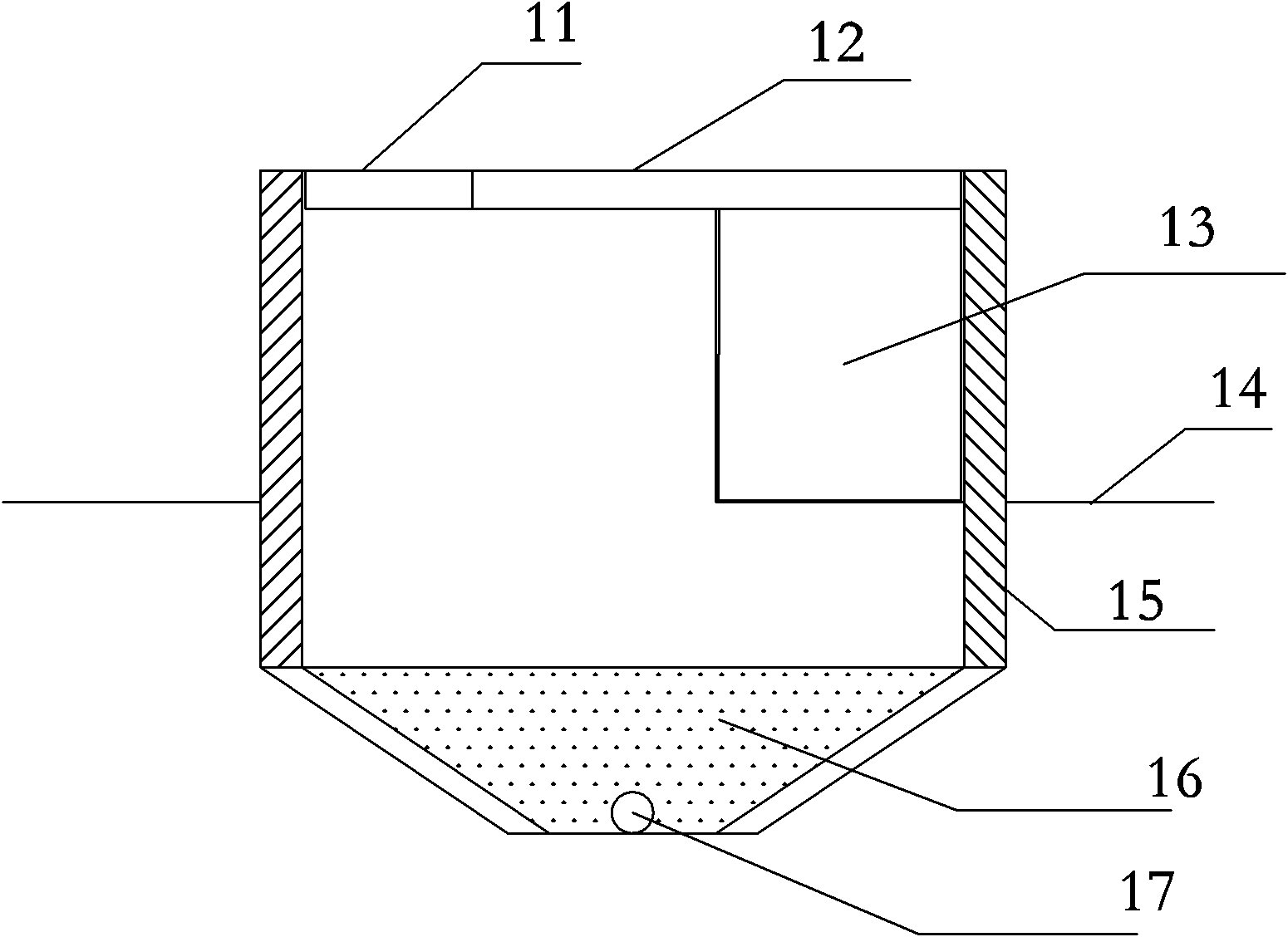

[0042] In Dajuge Village, Jixian County, Tianjin City, a two-stage anaerobic fermentation biogas production process of crop straw and livestock manure was used to treat rural organic waste. figure 1 ) and an anaerobic digester of 8 cubic meters underground (see figure 2 ), the acidification tank and the anaerobic digester are all cement structures. The lower part of the acidification tank is located below the ground level 14, and is provided with a feed inlet 11, a thermal insulation cover plate 12, and a discharge outlet 13. The tank wall 15 is a cement-sealed thermal insulation layer, and the bottom of the tank is provided with a gravel layer 16 and a drain pipe 17. The anaerobic biogas digester is constructed according to the "GB / T4750-2002 Household Biogas Digester Standard Atlas". The top of the pond is flush with the ground level 25, and has a sealing cover 21, a material inlet 22, a biogas outlet 23, and a material outlet 24. The pool body 26 is set as a cement sealin...

Embodiment 2-1

[0045] (1) Ingredients

[0046] 15 kg of corn stalks with a particle size of 10 mm, 15 kg of dry pig manure, 15 kg of dry sheep manure, and 45 kg of water

[0047] (2) Prepare and mix materials

[0048] Prepare 15 kg of corn stalks crushed to a particle size of 10 mm, 30 kg of a mixture of dry pig manure and dry sheep manure, and mix them evenly with 45 kg of water. 3 ;

[0049] (3-1) Start of acidification section

[0050] According to the above proportion of ingredients, feed the uniformly mixed material to the 4 / 5 of the volume of the acidification tank at one time, stay for 7 days, the pH of the acidification tank is stable between 4.5-6, the start-up process is completed, and start to continuously feed and discharge materials;

[0051] (3-2) Acidification stage reaction

[0052] Mix the homogeneous material at 0.15m 3 Put it into the acidification tank every day, the temperature of the acidification section is 25-30°C, and the material is discharged after a residence t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com