Constant-temperature biogas tank with sewage source heat pump

A sewage source heat pump and biogas digester technology, applied in water/sludge/sewage treatment, heat recovery system, climate sustainability, etc., can solve environmental damage and other problems, achieve the effect of increasing gas production rate and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

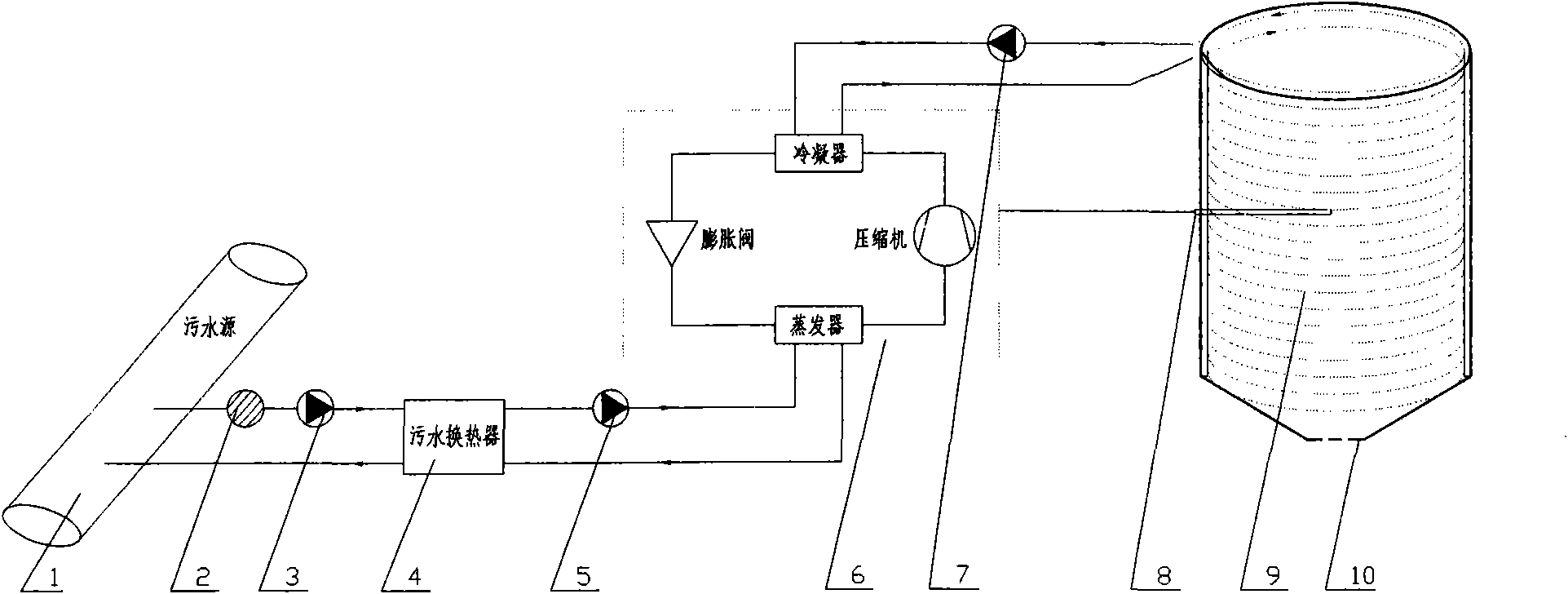

[0012] The present invention includes: sewage source 1, automatic filter 2, sewage circulating pump 3, sewage heat exchanger 4, circulating water pump 5, sewage source heat pump unit 6, circulating water pump 7, temperature sensor 8, heating coil 9 and biogas digester 10. Such as figure 1 As shown, the sewage source 1 can be industrial waste water, domestic sewage and other pipelines or other forms of sewage, and the temperature of the sewage is generally above 15°C, or even higher. A water intake pipe and a return water pipe are arranged in the sewage source 1, and a loop is formed by a fully automatic filter 2, a sewage circulation pump 3 and a sewage heat exchanger 4. The function of the fully automatic filter 2 is to perform primary filtration on the sewage, remove larger impurities and blockages, and perform backwashing and anti-clogging treatment, so as to provide guarantee for the long-term stable supply of the sewage source 1 . The sewage circulation pump 3 provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com