Novel vertical flexible covering film anaerobic fermentation device

An anaerobic fermentation and flexible technology, applied in biochemical instruments, waste fuels, biochemical equipment and methods, etc., can solve the problems of high equipment airtightness and compressive strength, high operation and maintenance costs, unfavorable biogas generation, etc. Achieve the effect of solving the problem of microbial loss, environmental benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

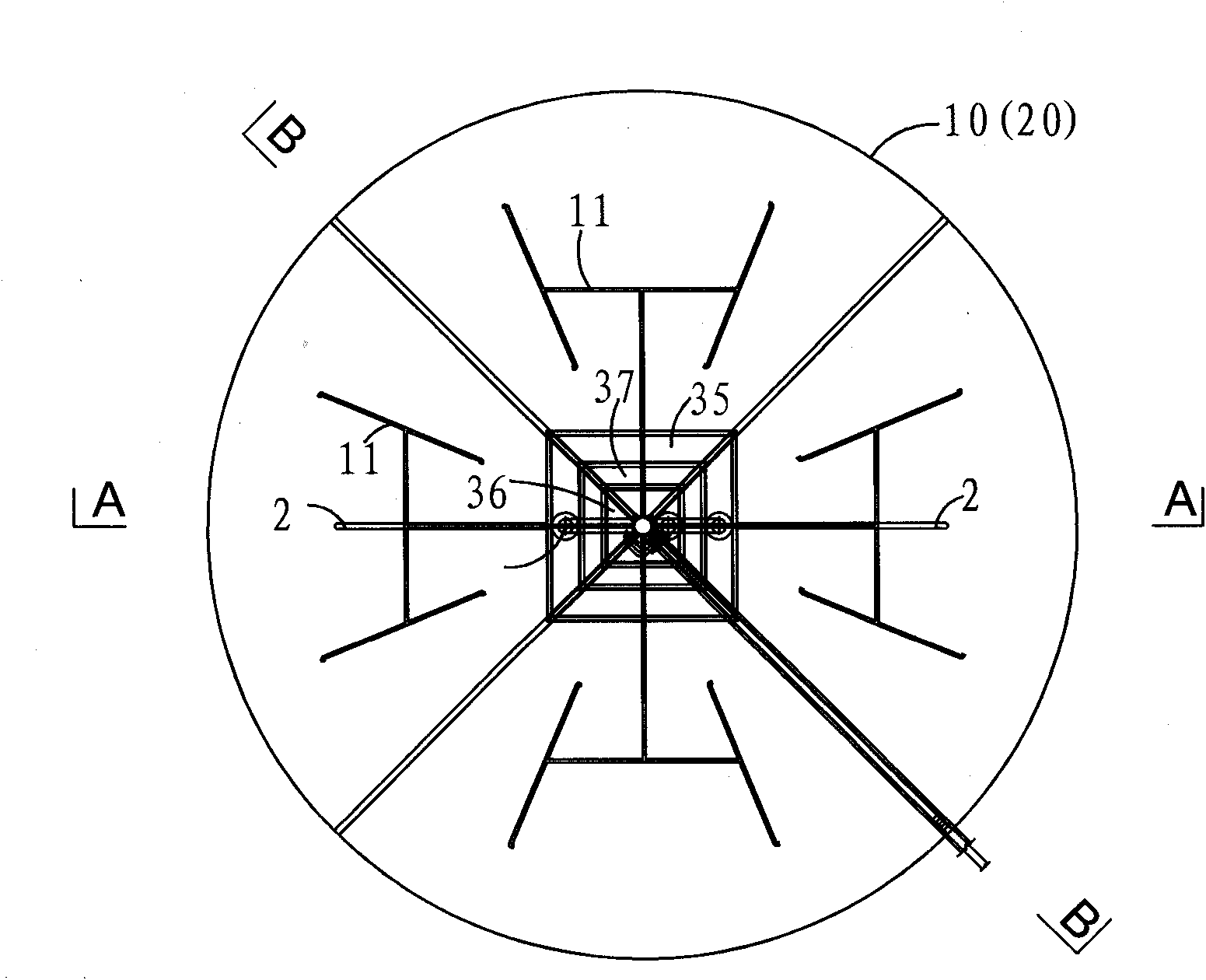

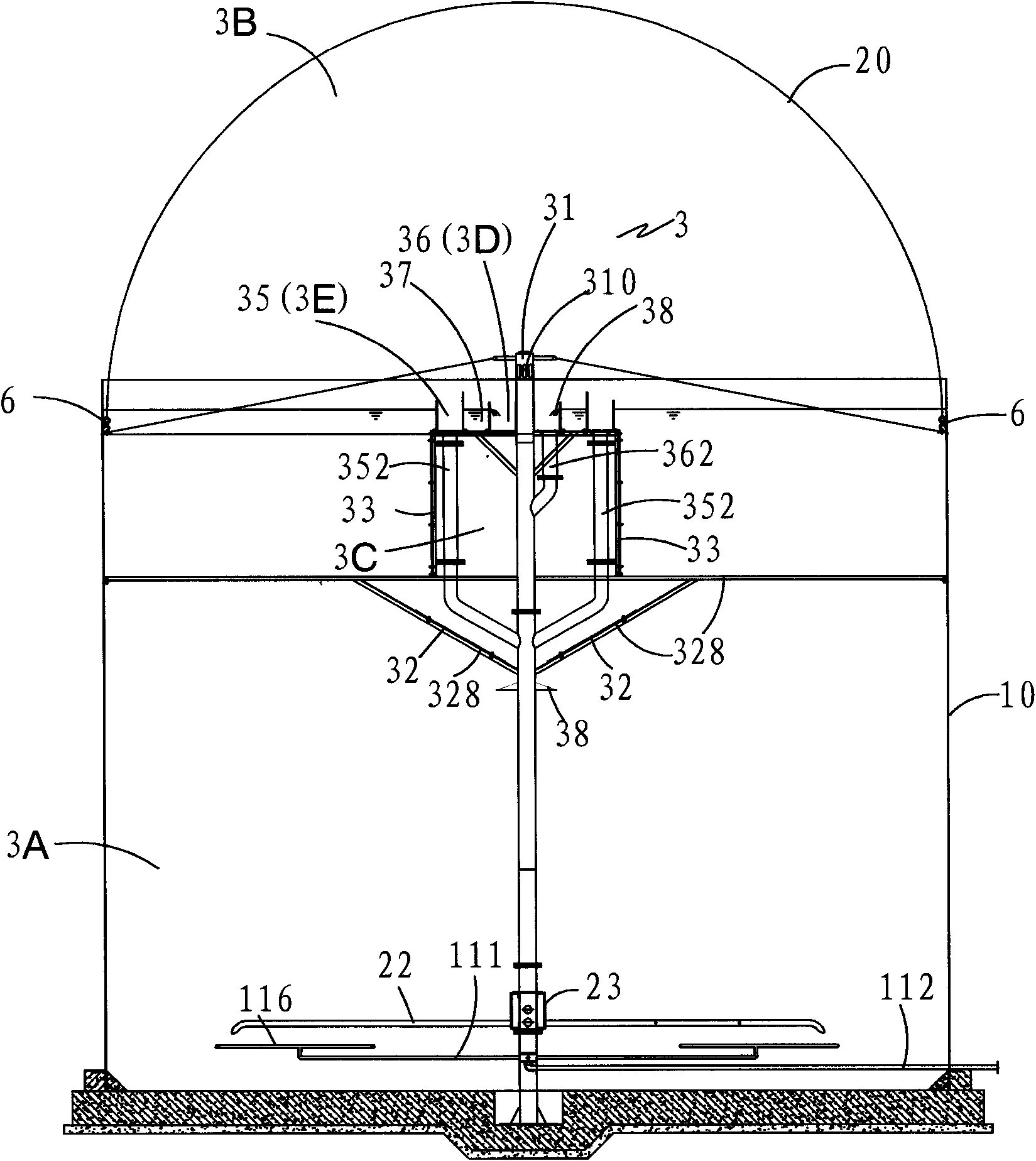

[0026] see Figure 1 to Figure 7 As shown, the novel vertical flexible film-covered anaerobic fermentation device of the present invention comprises an anaerobic fermentation reactor 10 and a flexible covering 20 fixed on the anaerobic fermentation reactor, and the anaerobic fermentation reactor 10 is automatically A biogas stirring device 1, a multi-point self-rotating water distribution device 2, and a four-phase separator 3 are arranged from bottom to top.

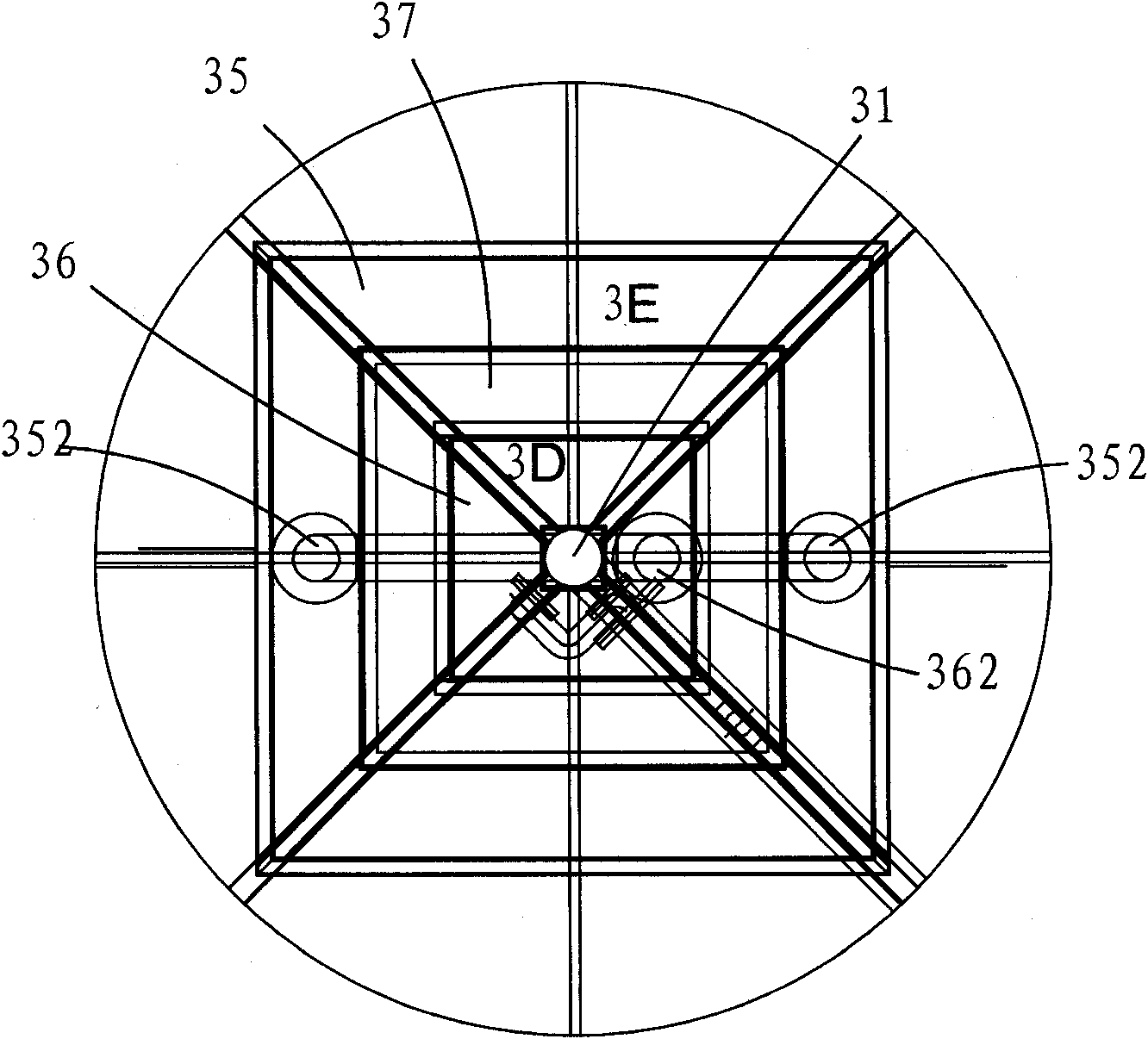

[0027] Again Figure 1 to Figure 3 As shown, the four-phase separator 3 includes a central column 31 that can support the four-phase separator, and a reaction zone 3A, a gas collection zone 3B, a settling zone 3C, A water discharge zone 3D and a slag discharge zone 3E, the reaction zone 3A, the settling zone 3C, the water discharge zone 3D and the slag discharge zone 3E are all located below the liquid level, and the reaction zone 3A is at the bottom of the four-phase separator, And the slag discharge area 3E and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com