Comprehensive utilization method of titanium-containing waste residues

A technology of titanium waste slag and titanium dioxide, which is applied in the field of comprehensive utilization of titanium-containing waste slag, can solve environmental pollution and other problems, and achieve the effects of solving environmental pollution, no secondary pollution, and reducing consumption of raw materials and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

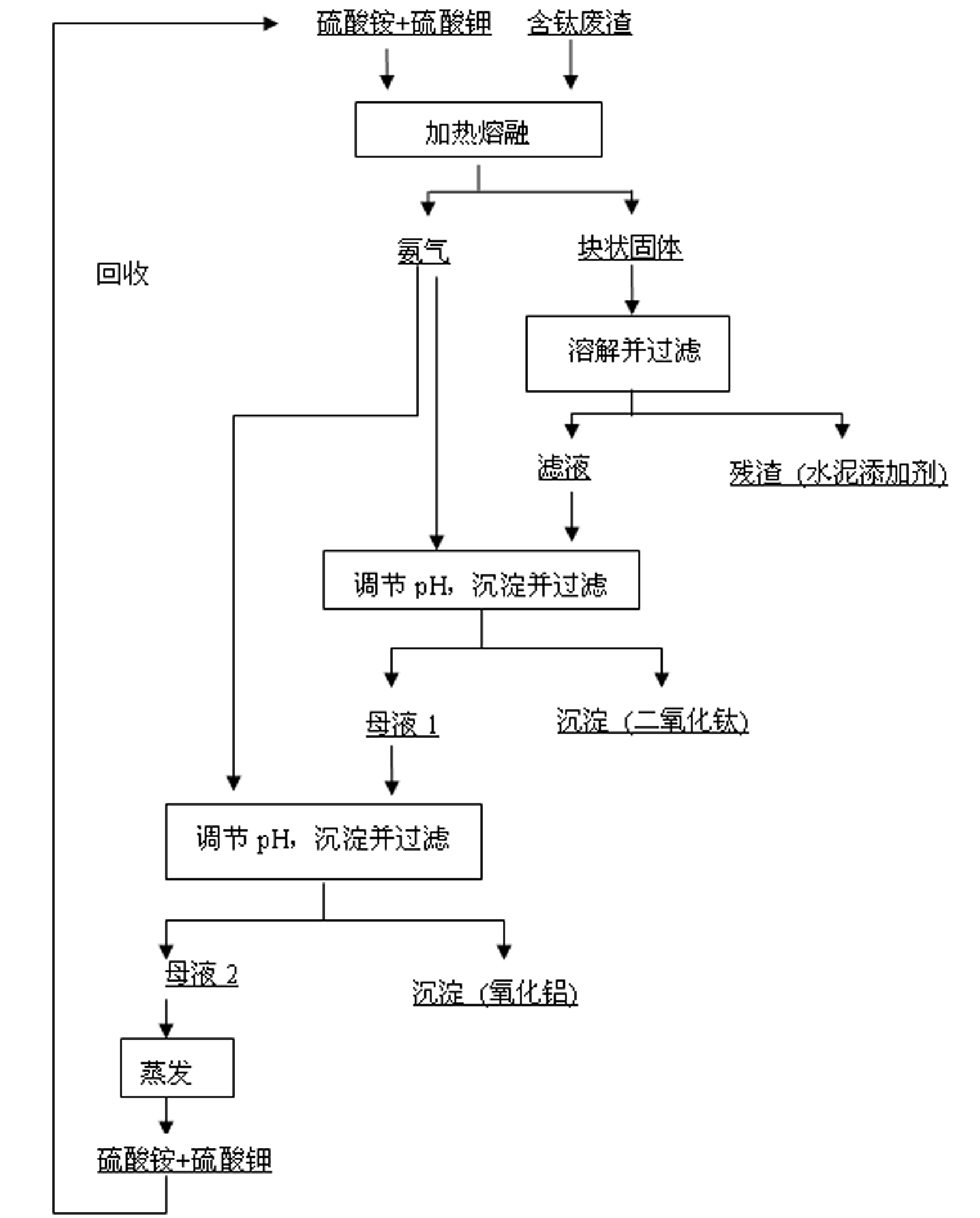

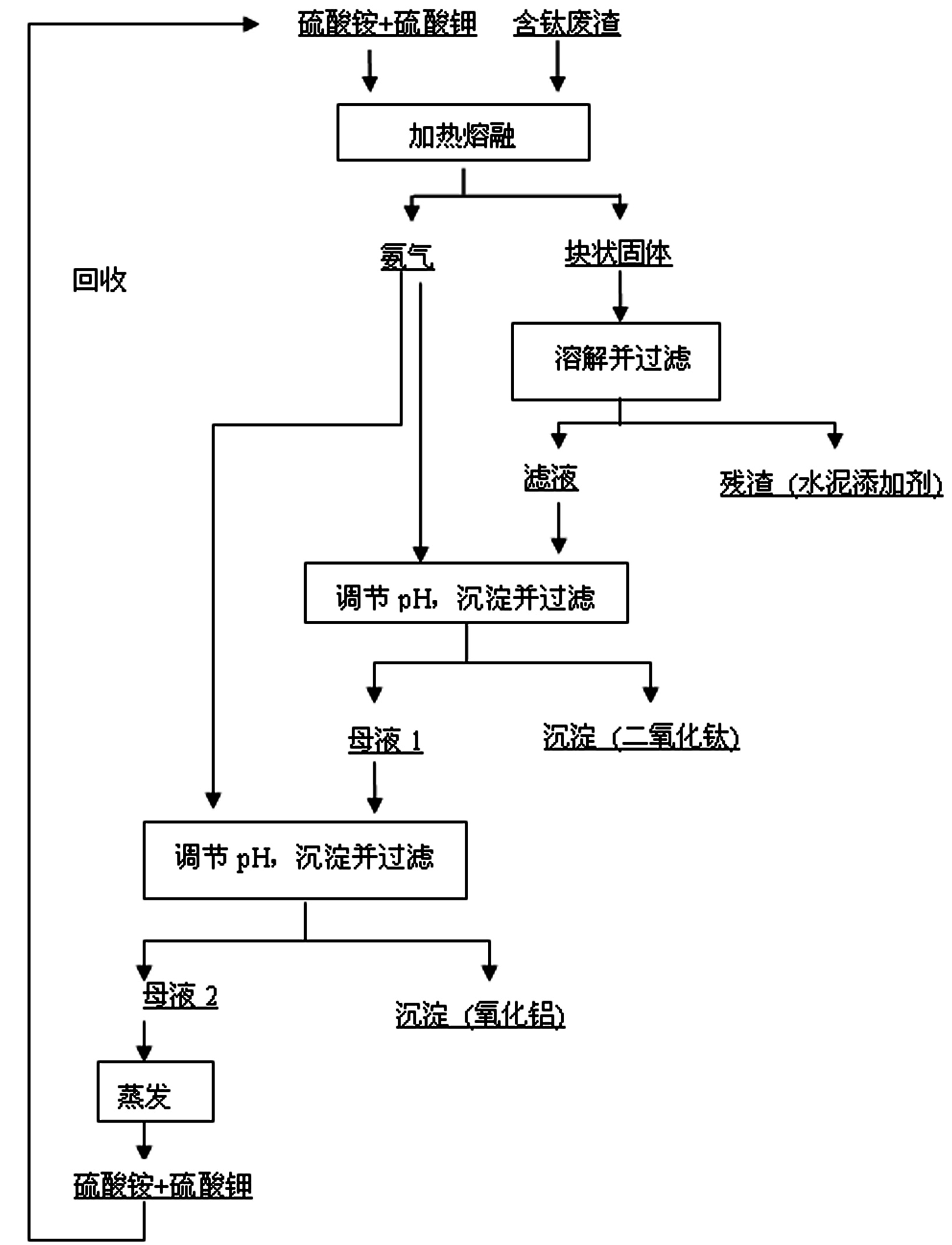

Method used

Image

Examples

Embodiment 1

[0026] (1) Crushing and grinding: the titanium-containing waste residue containing 4% by weight of titanium dioxide is crushed and ground to obtain a powder with a diameter of 50 μm;

[0027] (2) Mixing: According to the weight ratio of titanium-containing waste residue powder: ammonium sulfate: potassium sulfate=1:4:8, weigh the raw materials, mix the titanium-containing waste residue powder with ammonium sulfate, and then mix it with potassium sulfate evenly;

[0028] (3) Melting: raise the temperature of the above mixed material to 370°C and keep it warm for 50 minutes to obtain massive solid and ammonia gas;

[0029] (4) Dissolving and filtering: Dissolve the above massive solid in water, then filter to obtain the filtrate and residue, the water-soluble titanium in the filtrate accounts for 97.1% of the total weight of titanium in the titanium-containing waste residue, and the water-soluble aluminum accounts for 97.1% of the total weight of titanium in the titanium-containi...

Embodiment 2

[0034] (1) Crushing and grinding: the titanium-containing waste residue containing 33% by weight of titanium dioxide is crushed and ground to obtain a powder with a diameter of 150 μm;

[0035] (2) Material mixing: according to the weight ratio of titanium-containing waste residue powder: ammonium sulfate: potassium sulfate=1:12:5, weigh the raw materials, mix the titanium-containing waste residue powder with ammonium sulfate, and then mix with potassium sulfate evenly;

[0036] (3) Melting: raise the temperature of the above-mentioned mixed material to 480°C and keep it warm for 3 minutes to obtain massive solid and ammonia gas;

[0037] (4) Dissolving and filtering: Dissolve the above massive solid in water, and then filter to obtain the filtrate and residue. The water-soluble titanium in the filtrate accounts for 98.9% of the total weight of titanium in the titanium-containing waste residue, and the water-soluble aluminum accounts for 98.9% of the total weight of titanium in...

Embodiment 3

[0042] (1) Crushing and grinding: the titanium-containing waste residue containing 21% by weight of titanium dioxide is crushed and ground to obtain a powder with a diameter of 95 μm;

[0043](2) Weigh the raw materials according to the weight ratio of titanium-containing waste residue powder: ammonium sulfate: potassium sulfate = 1:9:2, mix the titanium-containing waste residue powder with ammonium sulfate, and then mix with potassium sulfate evenly;

[0044] (3) Melting: raise the temperature of the above mixed material to 240°C and keep it warm for 32 minutes to obtain massive solid and ammonia gas;

[0045] (4) Dissolving and filtering: Dissolve the above massive solid in water, and then filter to obtain the filtrate and residue. The water-soluble titanium in the filtrate accounts for 97.5% of the total weight of titanium in the titanium-containing waste residue, and the water-soluble aluminum accounts for 97.5% of the total weight of titanium in the titanium-containing was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com