Adsorptive separation composite fiber film, preparation method and uses thereof

A composite fiber membrane, adsorption and separation technology, applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of secondary pollution, loss, reunion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1) Disperse commercially available cellulose fiber (CF) (1g) in water (150ml), then slowly add concentrated sulfuric acid (2ml) dropwise while stirring;

[0076] 2) Add titanyl sulfate (TiOSO) dropwise to the above fiber dispersion 4 ) (0.8ml), while continuing to stir;

[0077] 3) Heating in a water bath at 70°C for 4 hours while stirring;

[0078] 4) After the reaction is completed, cool down, and then pour the reaction solution into a suction filter funnel with a diameter of 47mm for vacuum filtration to obtain a filter cake. The filter cake was taken out and then dried in a flat plate rapid heating dryer at 40°C for 8 hours to obtain TiO 2 / CF composite fiber membrane, denoted as Insitu TiO 2 / CF.

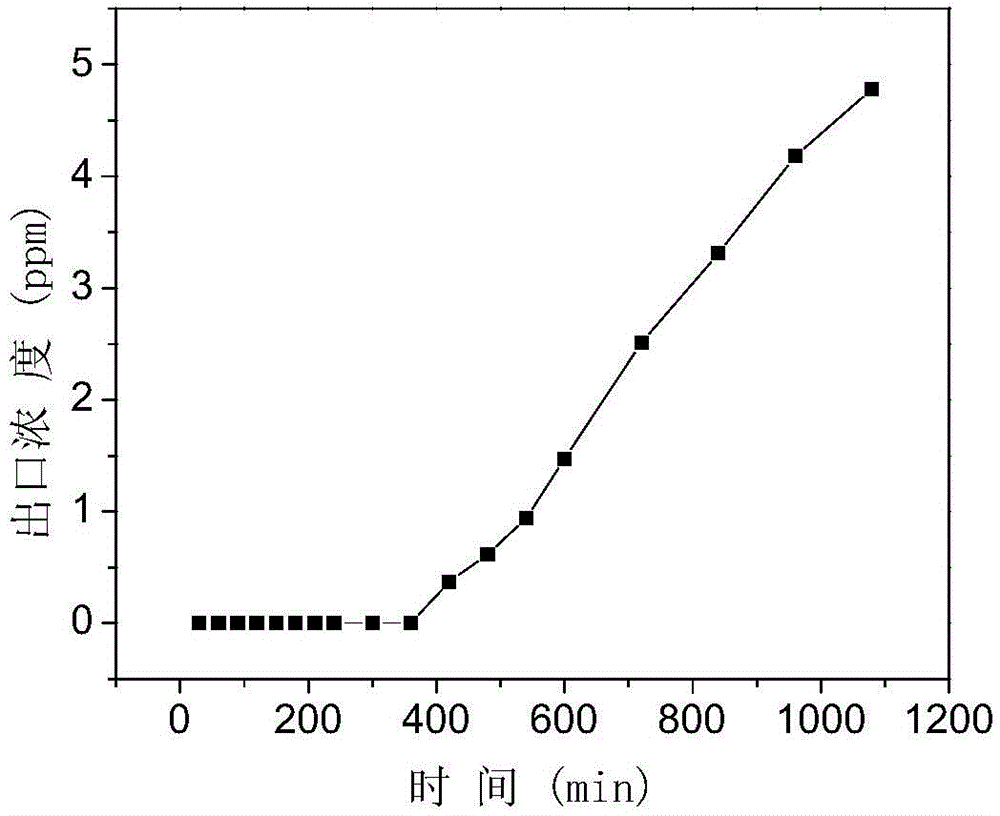

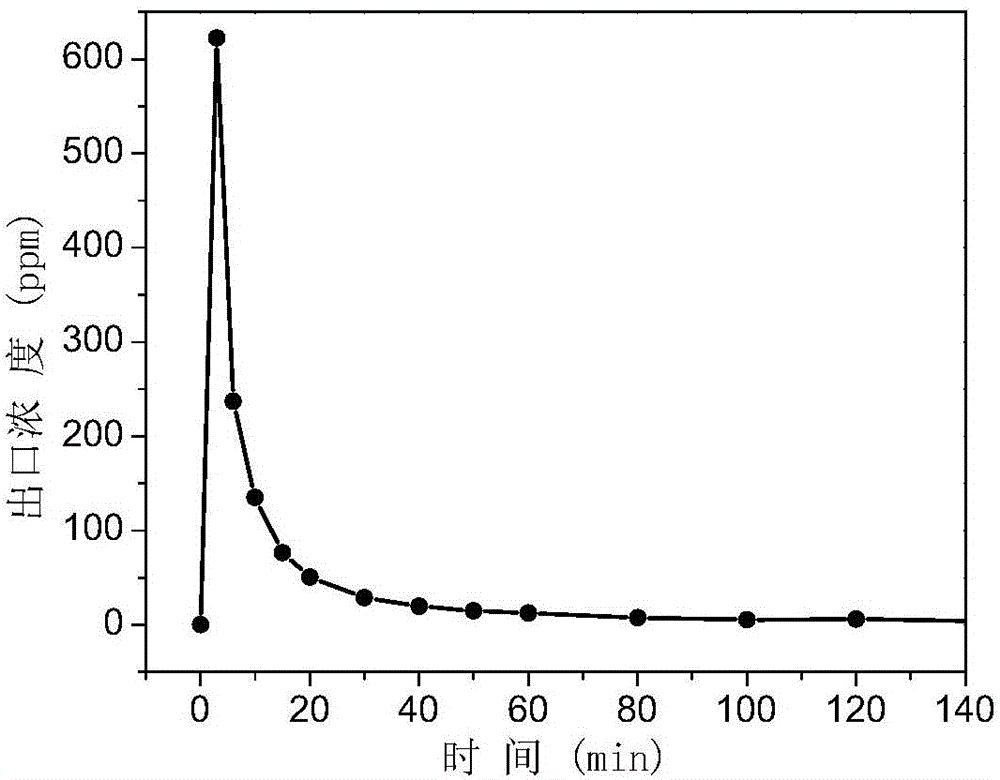

[0079] 5) Put two pieces of TiO 2 The / CF composite fiber membrane is installed in the filter as the filter medium, and the Pb with an initial concentration of 10ppm is sucked by the pump at 2.9ml / min 2+ Solution, after flowing through the filter medium, the filtra...

Embodiment 2

[0084] 1) Disperse commercially available cellulose fibers (1g) in water (200ml), then slowly add concentrated sulfuric acid (4ml) dropwise while stirring;

[0085] 2) Add TiOSO dropwise to the above fiber dispersion 4 (2.4ml), while continuing to stir;

[0086] 3) Heating in a water bath at 90°C for 3 hours while stirring;

[0087] 4) After the reaction is completed, cool down, and then pour the reaction solution into a suction filter funnel with a diameter of 47mm for vacuum filtration to obtain a filter cake. The filter cake was taken out and then dried in a flat plate rapid heating dryer at 30°C for 12 hours to obtain TiO2 / CF composite fiber membrane, denoted as Insitu TiO 2 / CF.

[0088] 5) Put a piece of TiO 2 The / CF composite fiber membrane is installed in the filter as the filter medium, and the Pb with an initial concentration of 10ppm is sucked by the pump at 5.8ml / min 2+ Solution, after flowing through the filter medium, the filtrate is collected at different...

Embodiment 3

[0091] 1) 50mg of commercially available TiO 2 (Anatase) nanoparticles were added to 200ml of deionized water, adjusted to a pH of 3, and ultrasonically dispersed for 1 hour to obtain a uniform and stable dispersion.

[0092] 2) Immerse 1 g of cellulose fibers with negatively charged surfaces in the above dispersion liquid, and let stand for 20 minutes.

[0093] 3) Pour the above reaction solution into a suction filter funnel with a diameter of 47 mm for vacuum filtration to obtain a filter cake. The filter cake was taken out and then dried in a flat plate rapid heating dryer at 50°C for 6 hours to obtain TiO 2 / CF composite fiber membrane, denoted as Anatase / CF.

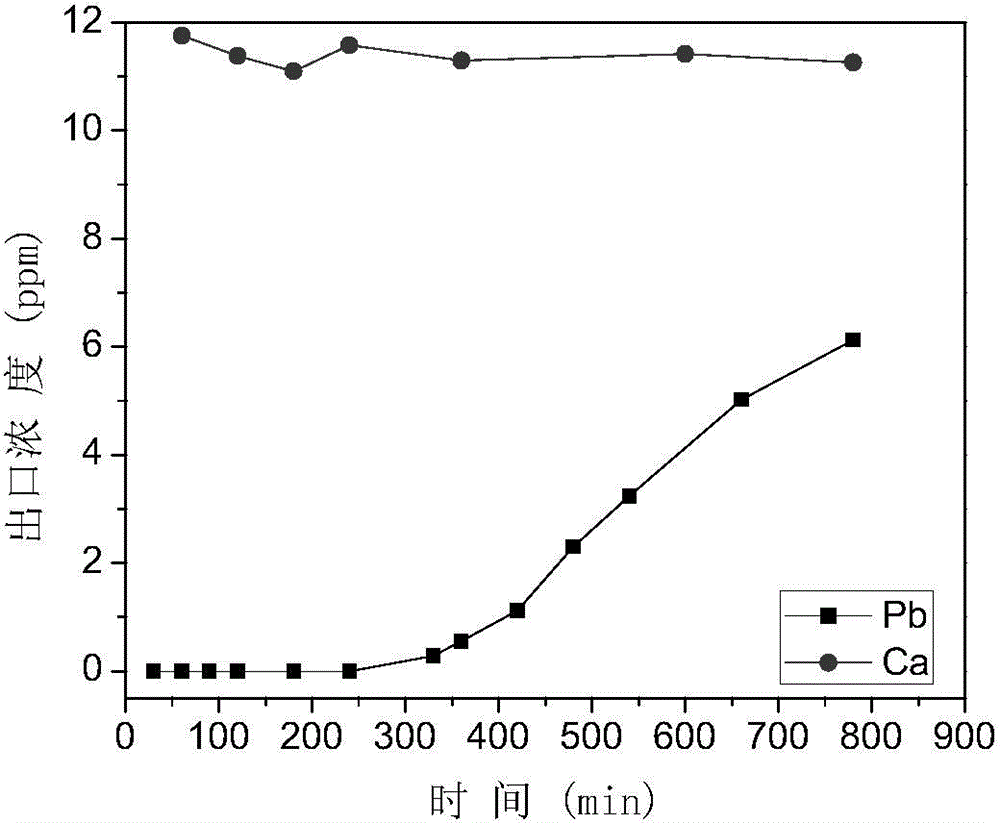

[0094] 4) Put two pieces of TiO 2 The / CF composite fiber membrane is installed in the filter as the filter medium, and the Pb with an initial concentration of 10ppm is sucked by the pump at 2.9ml / min 2+ Solution, after flowing through the filter medium, the filtrate is collected at different intervals, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com