A method for preparing biogas from kitchen waste, urban sludge and urban excrement

A technology for municipal sludge and kitchen waste, applied in biological sludge treatment, waste fuel, fermentation, etc., can solve the problems of incomplete fermentation of materials and low gas production rate, and achieve energy saving, high gas production rate, and material The effect of complete fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

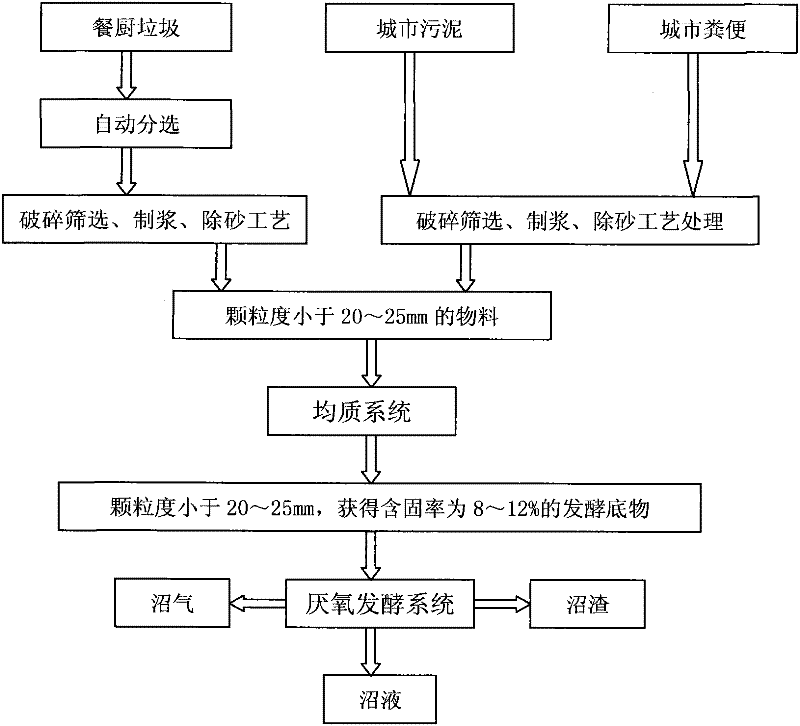

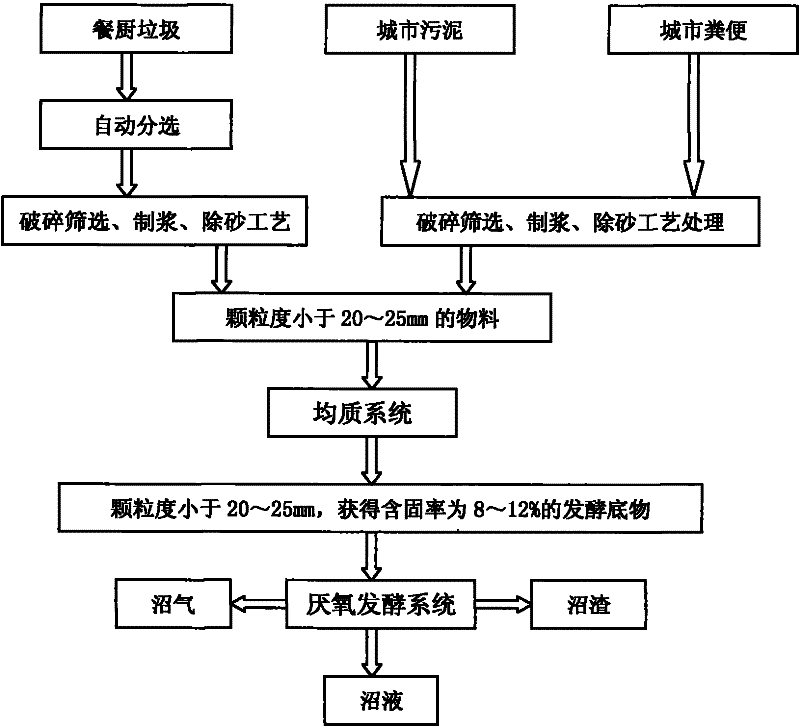

Image

Examples

Embodiment 1

[0020] (1) Pretreatment system

[0021] The food waste transported into the factory is directly sent to the receiving hopper (the bottom of the receiving hopper is equipped with a spiral dehydration device), and is automatically sorted (picking out various large bones, cooking utensils, long-fibrous packaging bags, tablecloths, ironware, etc. Foreign substances larger than 60mm), crushing, pulping, and sand removal; the remaining sludge in urban sewage treatment plants has a moisture content of more than 75%, while the urban feces has a water content of more than 80%, which is treated by pulping and sand removal; Food waste, urban sludge and urban excrement undergo a pretreatment process to obtain materials with a particle size of less than 20-25mm.

[0022] (2) Homogeneous system

[0023] After the treatment in step (1), the food waste material particles first enter the homogenizing tank, stir and heat to 35°C for 8-12 days for hydrolysis, then mix in feces and sludge materi...

Embodiment 2

[0031] (1) Pretreatment system

[0032] With embodiment 1.

[0033] (2) Homogeneous system

[0034] The material processed in step (1) is pumped into the homogenization tank for material homogenization. The above materials enter the homogenizing tank one after another. The kitchen waste first enters the homogenizing tank, then stirs and heats to 35°C for 8-10 days for hydrolysis, then mixes with feces and sludge for 2 hours of reaction, and then is pumped to the anaerobic fermentation tank . The temperature compensation system in the homogenizing tank adjusts the temperature of the material to 35°C, and the pH of the uniformly mixed material is adjusted to 6.5-7.5. The residence time of the mixed material in the homogenizing tank is about 2 hours, so that the particle size of the solid material Reduce to below 20-25mm, and adjust the carbon-nitrogen ratio (25:1-30:1) of the material at the same time, and the solid content rate is 8-12%.

[0035] (3) Anaerobic fermentation ...

Embodiment 3

[0042] (1) Pretreatment system

[0043] With embodiment 1.

[0044] (2) Homogeneous system

[0045] The material processed in step (1) is pumped into the homogenization tank for material homogenization. The above materials enter the homogenizing tank one after another. The food waste first enters the homogenizing tank, then stirs and heats to 35°C for 10-12 days for hydrolysis, then mixes with feces and sludge for 2 hours of reaction, and then is pumped to the anaerobic fermentation tank . The temperature compensation system in the homogenizing tank adjusts the temperature of the material to 35°C, and the pH of the uniformly mixed material is adjusted to 6.5-7.5. The residence time of the mixed material in the homogenizing tank is about 2 hours, so that the particle size of the solid material Reduce to below 20-25mm, and adjust the carbon-nitrogen ratio (25:1-30:1) of the material at the same time, and the solid content rate is 8-12%.

[0046] (3) Anaerobic fermentation sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com