Large-sized open mouthed combined methane tank

A biogas digester and composite technology, which is applied in the field of biogas digesters, can solve the problems of insufficient utilization of rural straw, difficulty in feeding and discharging of straw digesters, and unstable biogas pressure-stabilized gas supply, so as to achieve a convenient and uniform solution. The effect of feeding and discharging completely, simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

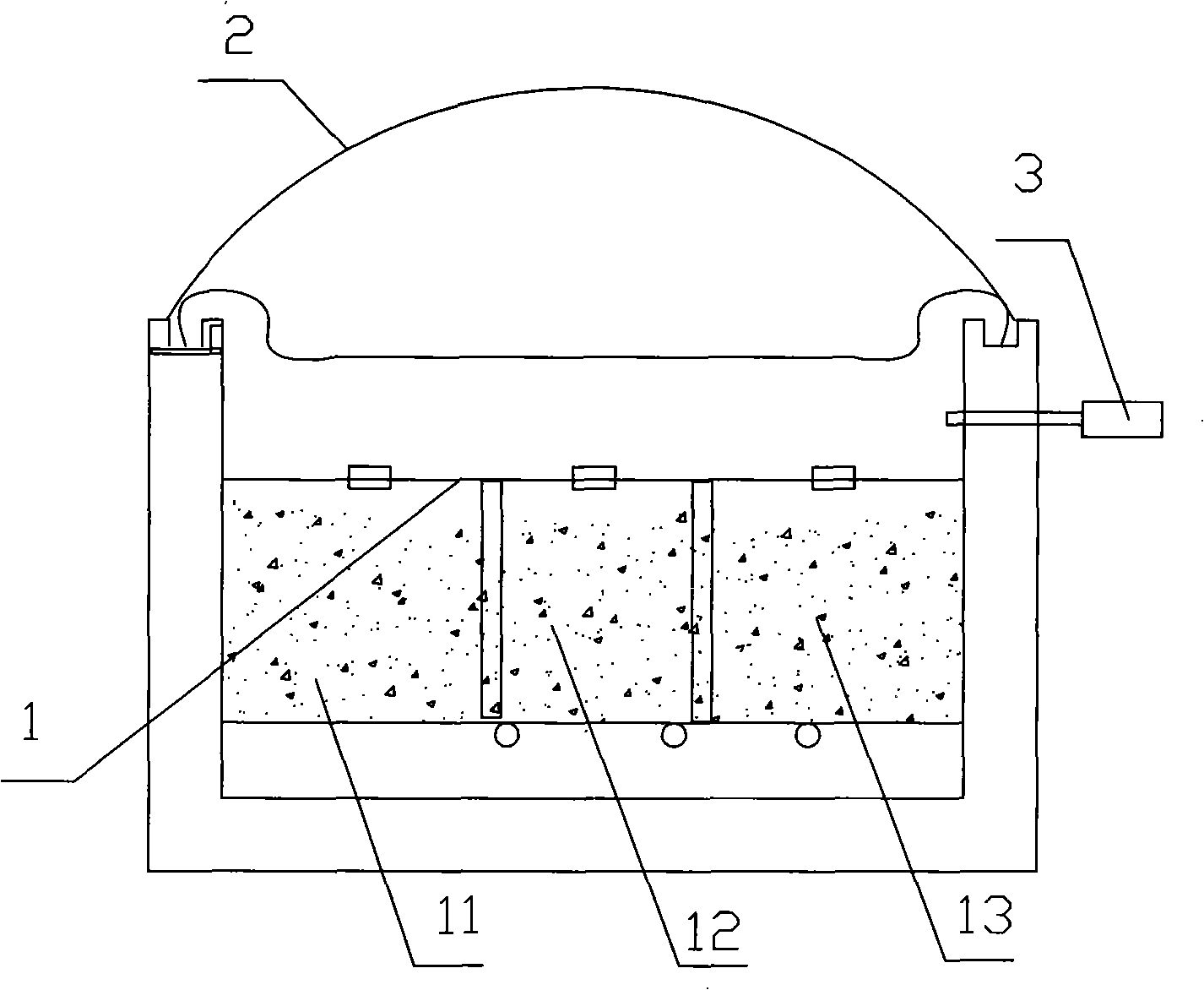

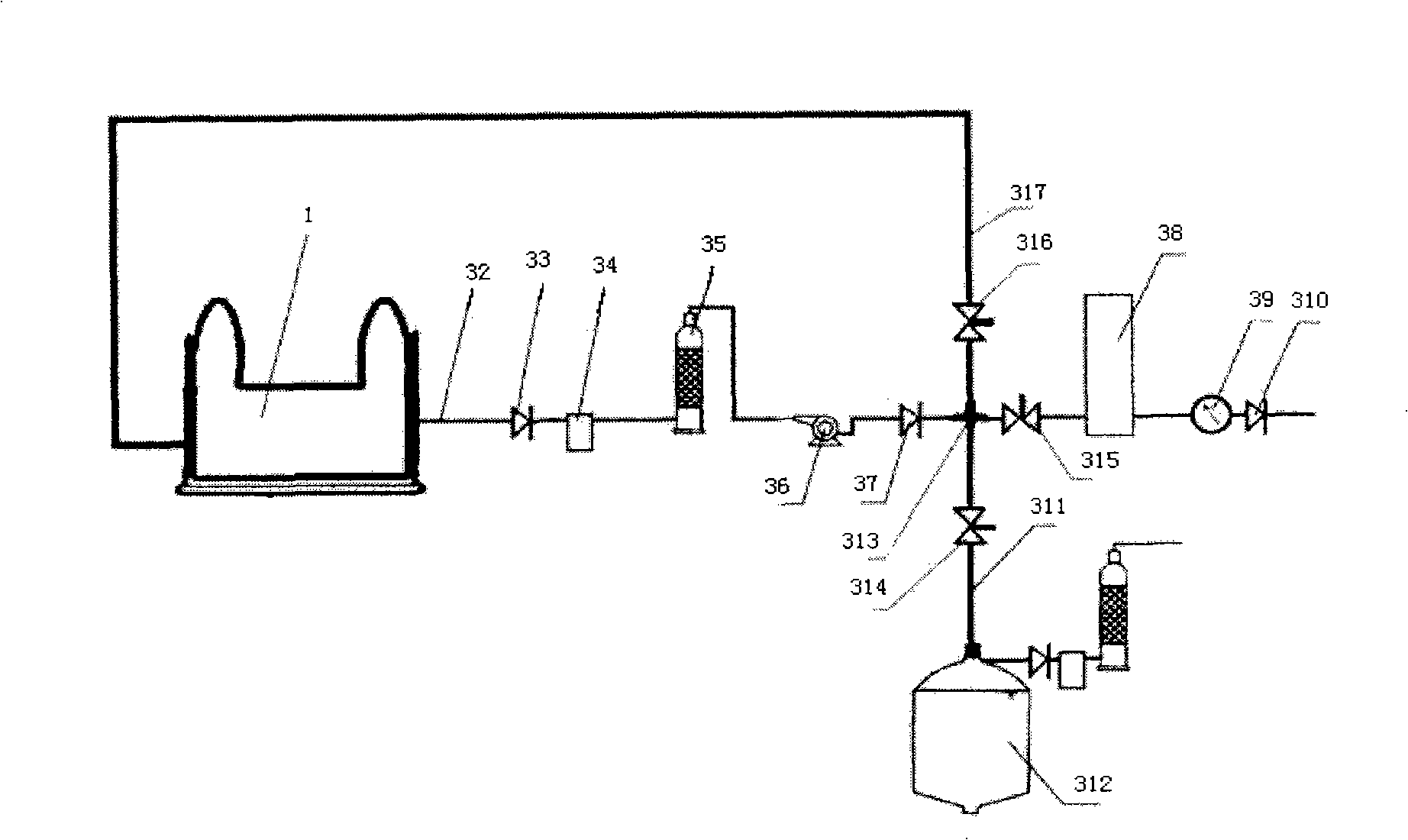

[0025] Such as figure 1 , Figure 7 As shown, the large-scale open compound biogas digester of the present invention comprises a fermentation tank 1, a gas supply device 3 connected to a gas collection and storage device 2 and the fermentation tank, and the fermentation tank 1 includes a plurality of independent sub-fermentation tanks 11, 12, 13, the sub-fermentation tanks can be connected or disconnected.

[0026] A large open compound biogas digester, at least one of the multiple independent fermentation tanks is a hydraulic fermentation tank 12 .

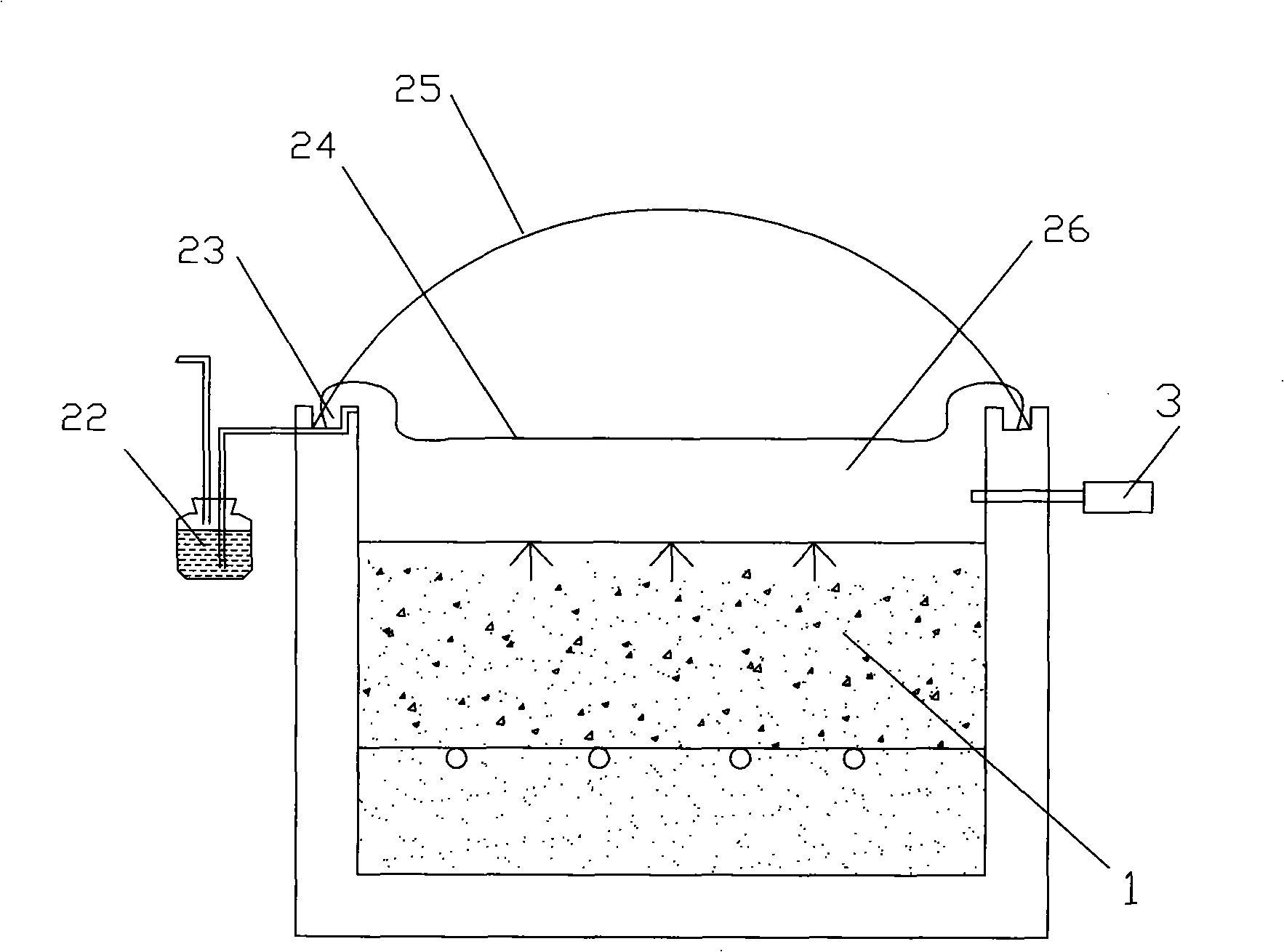

[0027] Such as figure 2 , Figure 7 The gas-collecting and gas-storage device 2 of the large open composite biogas digester shown is connected to the fermentation tank 1, and the upper part of the fermentation tank wall is provided with an annular water tank 23 along the tank wall, and the opening of the soft cover 24 is fastened in the ring-shaped water tank 23 , the ring-shaped water tank is filled with water, and the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com