A steel structure building connector for building

A technology for connecting parts and steel structures, which is applied in building construction, construction, etc., can solve the problems of increased working time at high altitude, falling tools at high altitude, hidden dangers to the safety of construction workers, etc., so as to reduce the carrying capacity and reduce the use of connecting bolts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

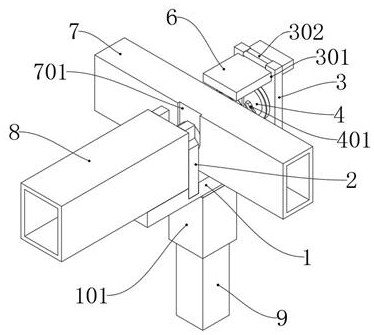

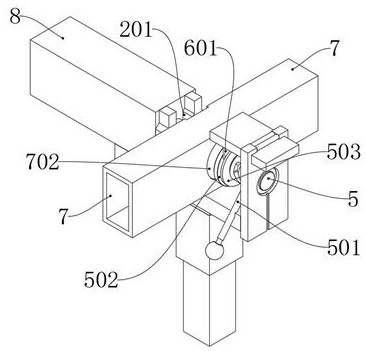

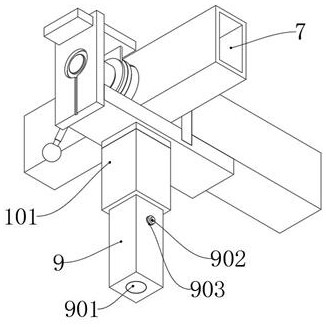

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a steel structure building connector for building, which comprises a connector main body 1; a hanging plate 2 is fixedly installed on the upper end of the connector main body 1 horizontally and vertically upward; a rear seat plate 3 is vertically fixedly installed on the rear end of the connector main body 1 ; The middle part of the front end face of the rear seat plate 3 is vertically fixed with a guide bushing 4; the rotation of the guide bushing 4 is installed with an extrusion column 5; The lower end of the part main body 1 is vertically equipped with a vertical tube 9; the hanging plate 2 is vertically forwardly clamped with a vertical tube 8; Figure 5 and Image 6As shown, the horizontal tube 7 includes a hanging groove 701, an inlay groove 702 and a sinking groove 703. The front side wall of the horizontal tube 7 is provided with a vertical hanging groove 701, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com