Full-automatic centrifugal tube plate cleaning and disinfecting device

A cleaning and disinfection, fully automatic technology, applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of inaccurate concentration of 84 liquid, harmful to personnel health, strong smell of 84 disinfectant, etc. Achieve the effect of avoiding the backflow of cleaning water, not easy to short-circuit damage, and shortening the manual operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

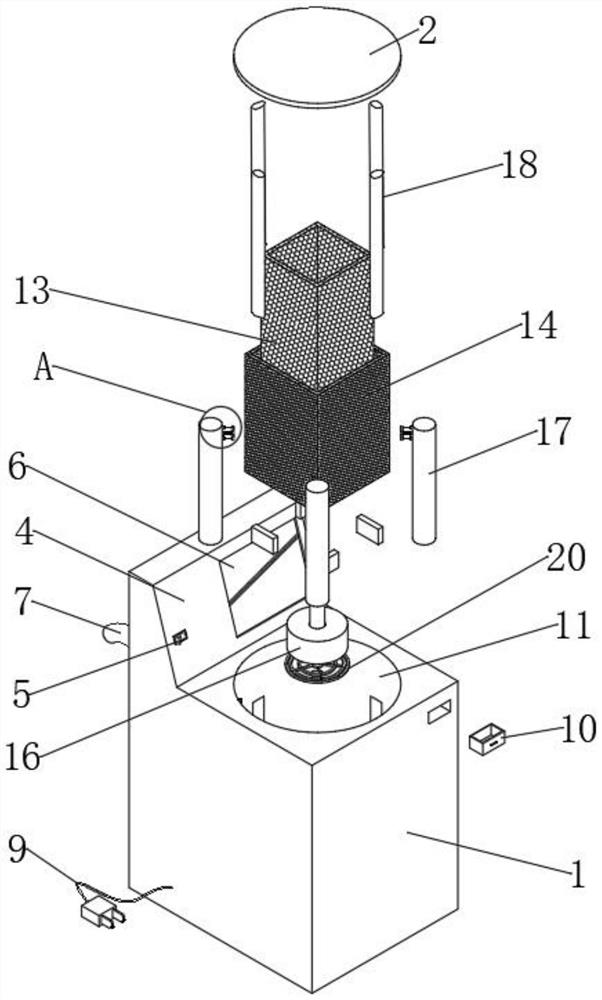

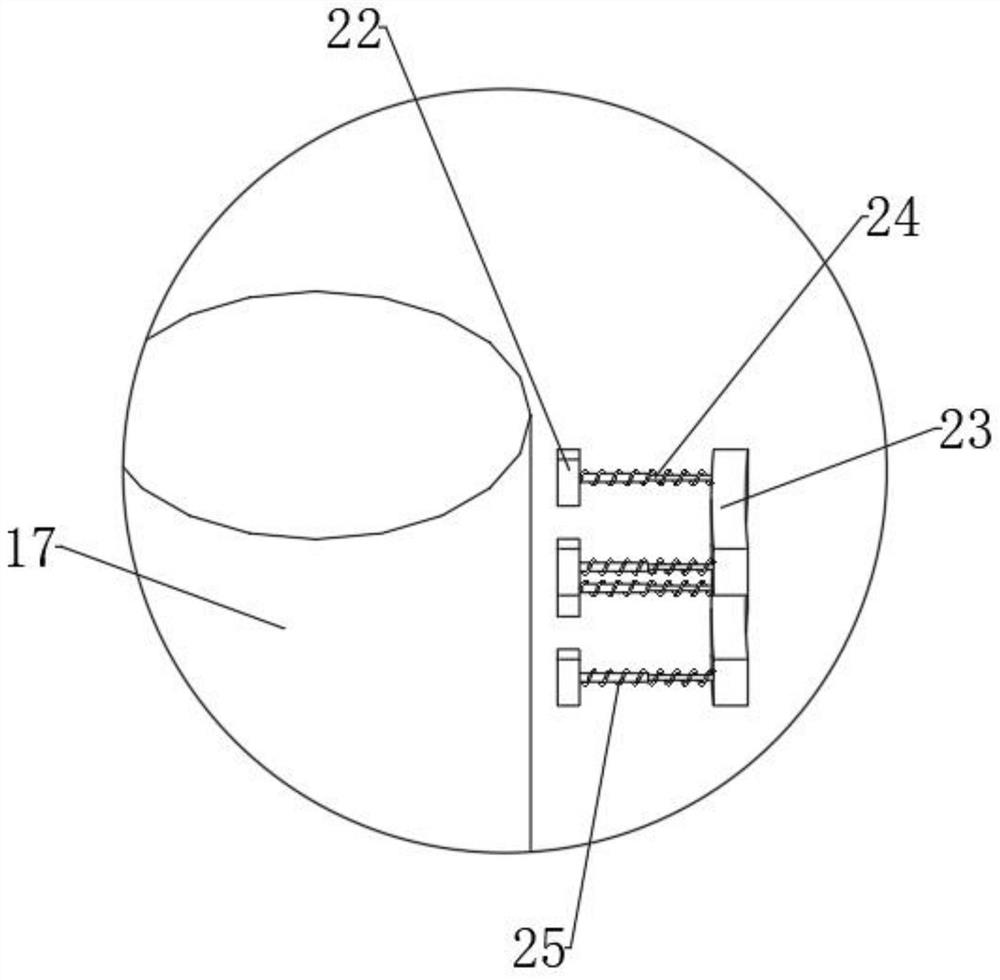

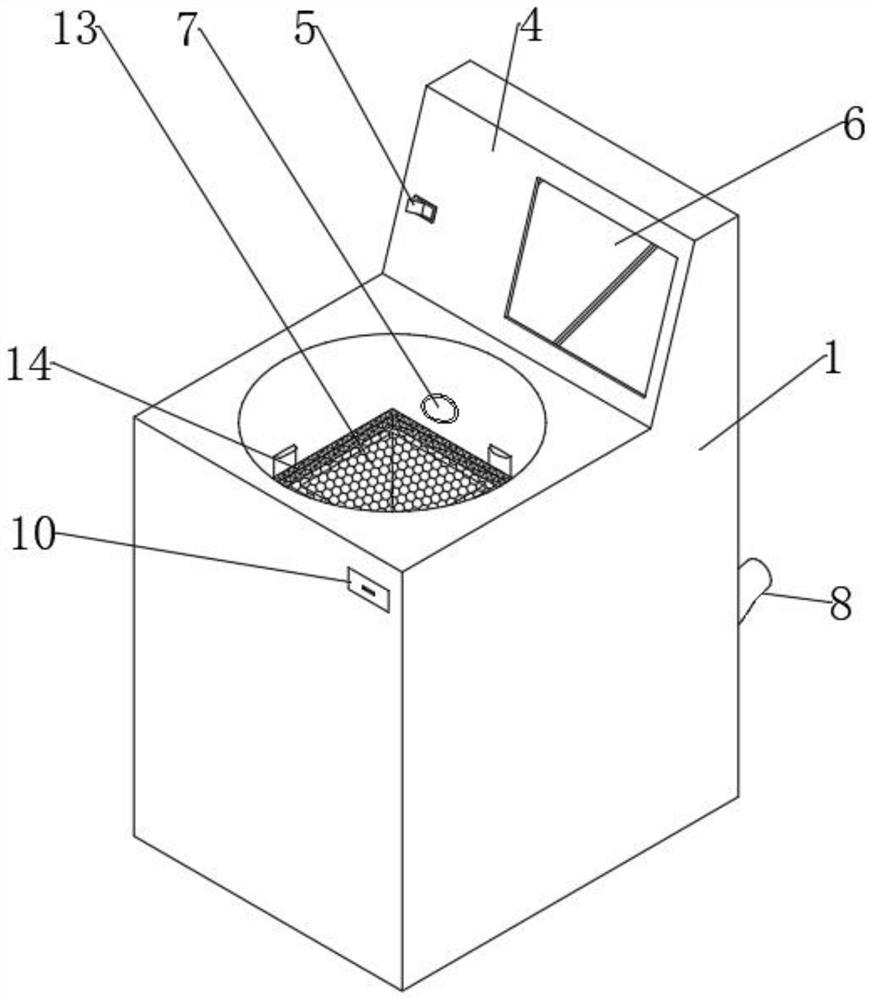

[0045] see figure 1 -and Figure 4-8 , a fully automatic centrifugal tube plate cleaning and disinfection device, comprising a cabinet body 1, a control panel 4 is fixedly connected to the upper end of the cabinet body 1, a power switch 5 and a touch display screen 6 are fixedly connected to the control panel 4, and embedded in the control panel 4 There is a control terminal for controlling the disinfection device and its corresponding circuit, and the power switch 5 and the touch display screen 6 are electrically connected to the control terminal. The bottom end of the cabinet 1 is fixedly connected with a plurality of bases 3, and the upper end of the cabinet 1 is excavated with a Water storage bin 11, the upper end of the cabinet body 1 is connected with a cabinet body cover 2 matching with the water storage bin 11, wherein the connection and disassembly of the cabinet body 1 and the cabinet body cover 2 are fixed by buckles, and the cabinet body 1 The rear end is fixedly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com