Feed conversion efficiency measuring device for mutton sheep

A feed conversion efficiency and measuring device technology, which is applied in measuring devices, material weighing, and analyzing materials, etc., can solve the problems of surplus feed waste, waste, and low measurement accuracy, so as to avoid difficult control, ensure accuracy, and broaden the The effect of practical range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

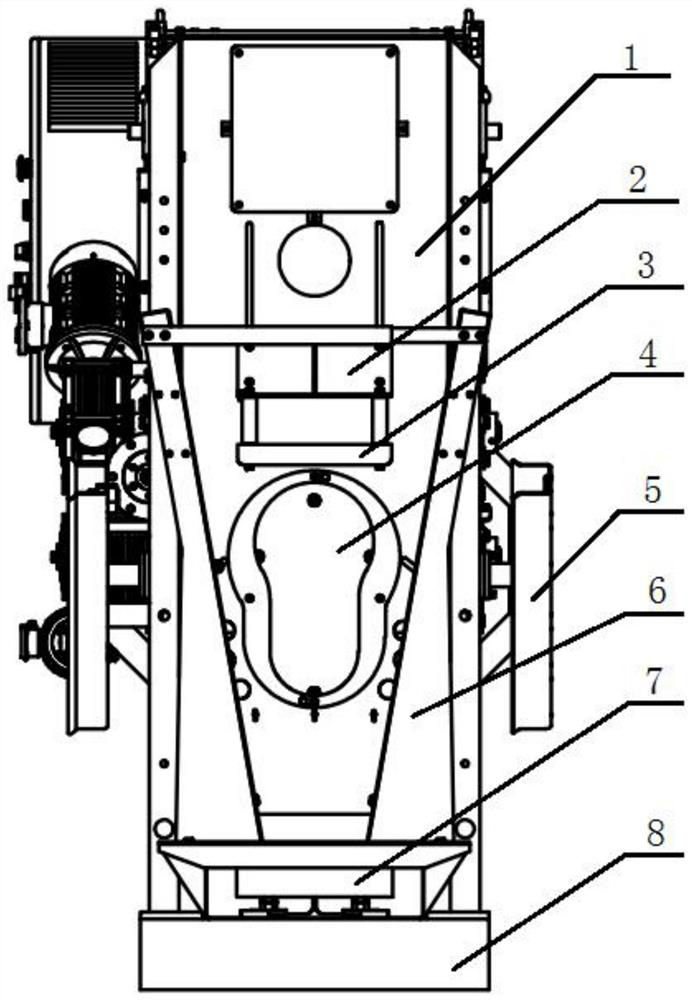

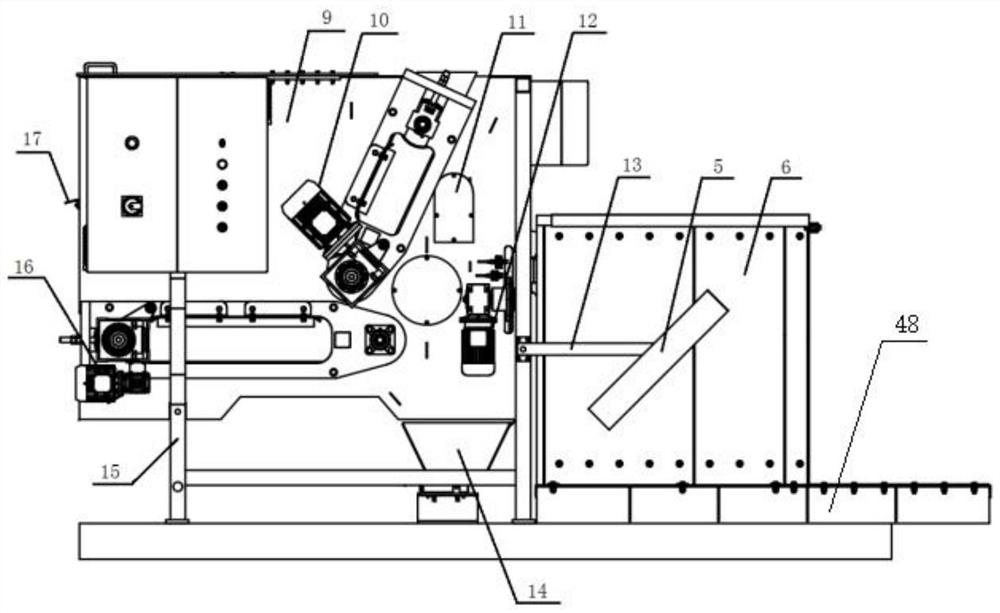

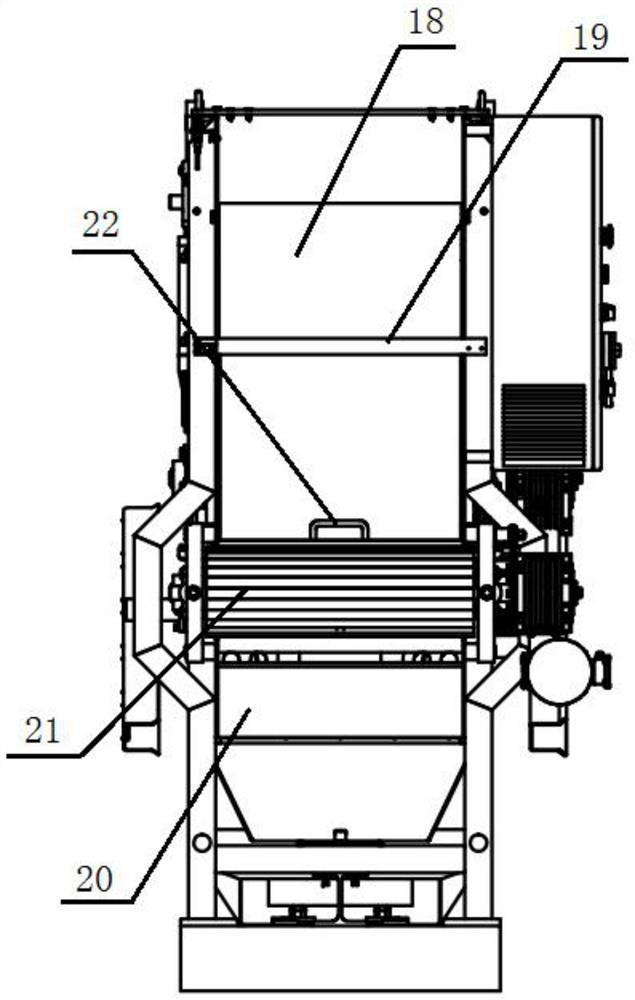

[0052] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0053] A TMR conversion efficiency measuring device for mutton sheep, the innovation of which is: a frame 15, a front wall 1, a side wall 9, an automatic feeding door, an ear tag recognition mechanism, an infrared proximity recognition mechanism, and a feeding mechanism , body weight weighing mechanism and feed weighing mechanism 14, front wall board and side wall plate are installed respectively at described frame front end and left and right sides, have feeding port at the lower end of front wall board, in feeding port An automatic feeding door is installed at the upper end of the feeding port, an ear tag identification mechanism is installed on the upper front wall of the feeding port, and an installation arm extending horizontally forward is installed on the two side wall panels, and the installation arm is equipped with an infrared proximity id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com