Kitchen waste, municipal sludge and forestry and agricultural residue fermentation tank ultrahigh-temperature aerobic fermentation composting method

A technology for agricultural and forestry waste and kitchen waste, which is applied in the field of organic solid waste treatment and renewable energy treatment, can solve problems such as no unified treatment method, and achieve the effects of fast decomposition of organic matter, high fermentation temperature, and short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

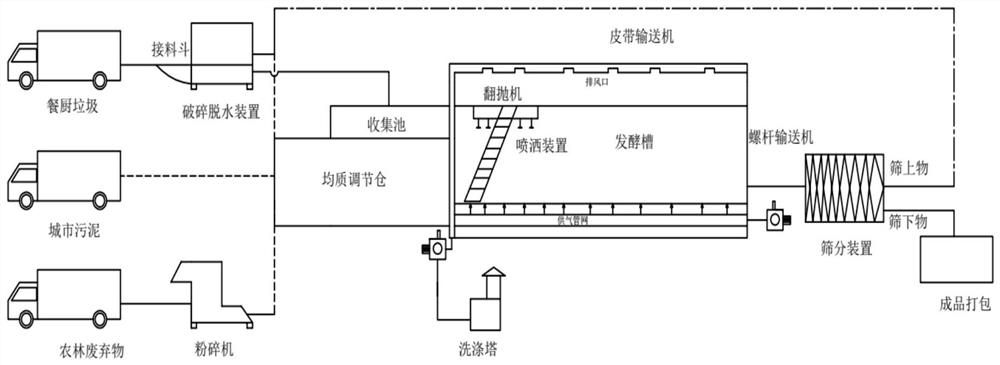

[0035] In a certain area of Wuhan, kitchen waste, urban sludge, and agricultural and forestry waste were collected and subjected to high-temperature aerobic fermentation using the process of the present invention. The water content of food waste was 81%, 8 tons, and the water content of urban sludge was 83%, 4 tons, 2 tons of agricultural and forestry waste, such as figure 1 As shown, it specifically includes the following steps:

[0036] (1) Pretreatment

[0037] After the food waste is collected, it is sent by the transport vehicle to the hopper in the workshop, and the hopper is lifted to the crushing and dehydration device. While the food waste is crushed, the moisture in the waste is squeezed out, and the particle size and moisture content of the material after crushing and extrusion 5mm and 65%, the crushed and dehydrated materials are transported by the belt into the homogeneous adjustment bin, and the liquid is collected and temporarily stored in the collection pool...

Embodiment 2

[0053] In a certain area of Wuhan, kitchen waste, urban sludge, and agricultural and forestry waste were collected and subjected to high-temperature aerobic fermentation using the process of the present invention. The water content of food waste was 85%, 12 tons, and the water content of urban sludge was 86%, 6 1 ton, 3 tons of agricultural and forestry waste, 9 tons of backmixed material with a moisture content of 26%,; if figure 1 As shown, it specifically includes the following steps:

[0054] (1) Pretreatment

[0055] After the food waste is collected, it is sent by the transport vehicle to the hopper in the workshop, and the hopper is lifted to the crushing and dehydration device. While the food waste is crushed, the moisture in the waste is squeezed out, and the particle size and moisture content of the material after crushing and extrusion 5mm and 65%, the crushed and dehydrated materials are transported by the belt into the homogeneous adjustment bin, and the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com