Sludge organic fertilizer for forestry and afforestation and preparation method thereof

An organic fertilizer and sludge technology, which is applied in the formulation and preparation of organic fertilizer components for forestry afforestation, can solve the problem of in-situ fertilization technology in small and medium-sized sewage treatment plants. , long composting cycle and other issues, to achieve the effect of expanding the scope of utilization, improving composting efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

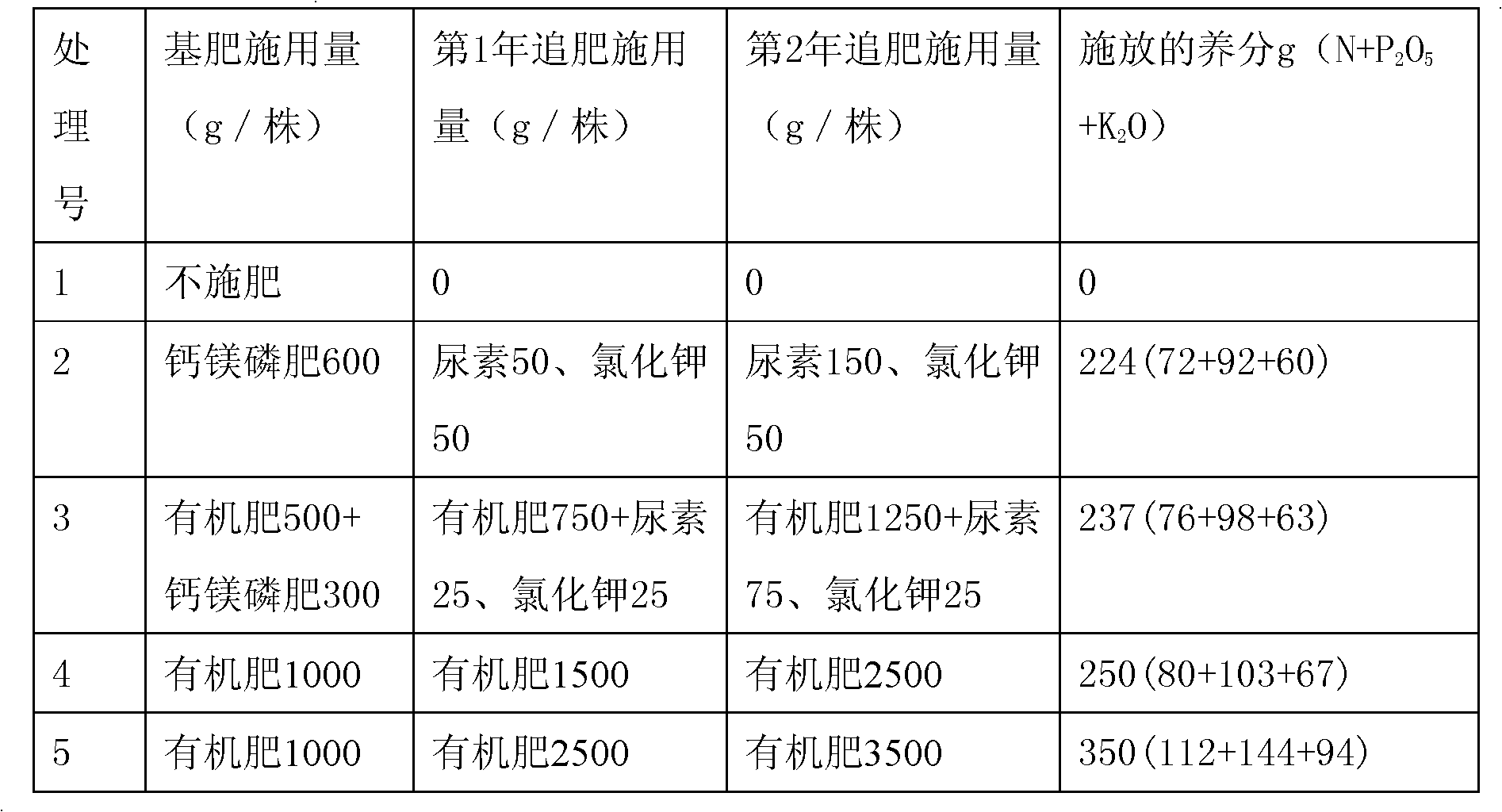

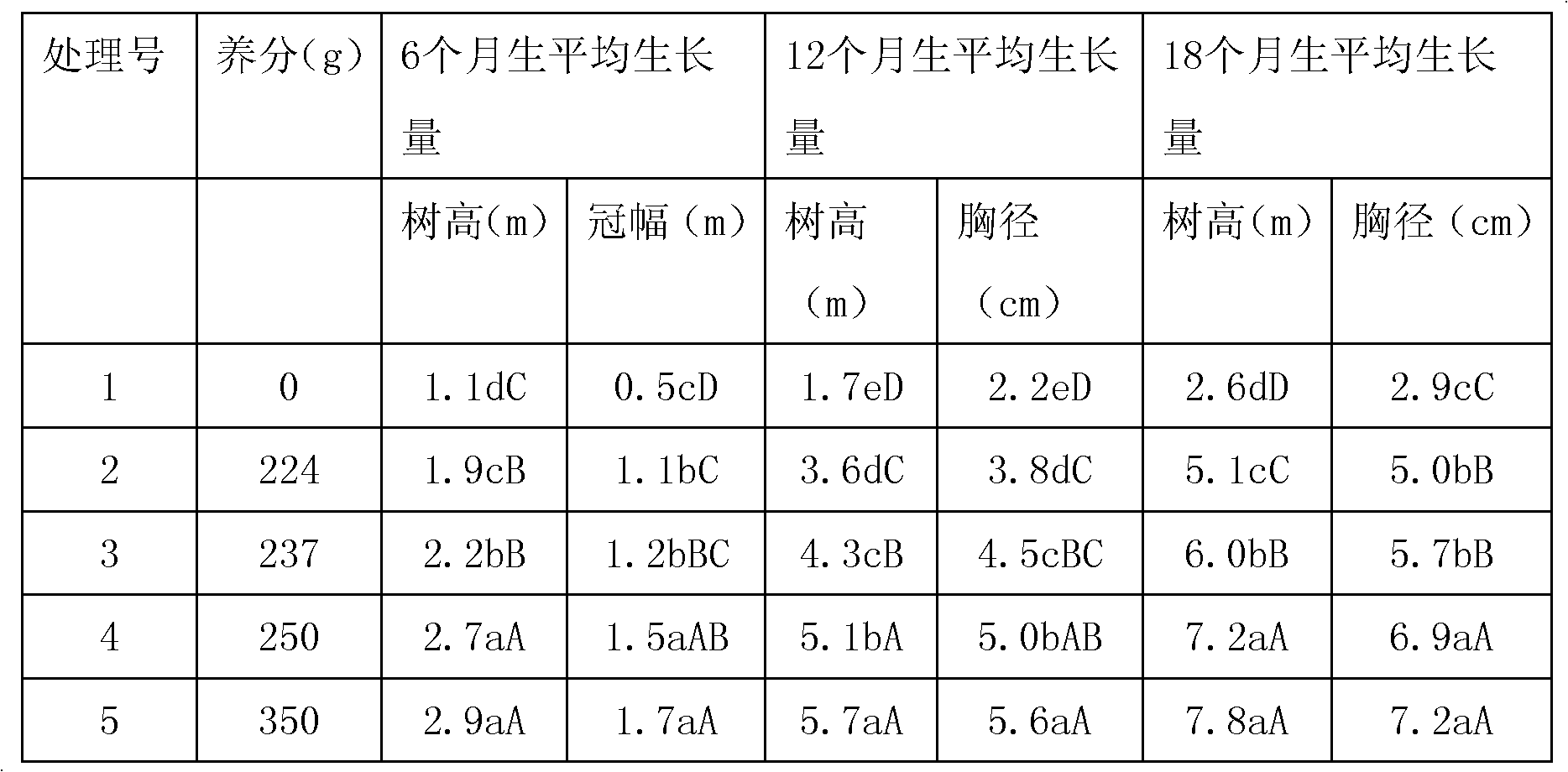

[0022] Embodiment one fertilizer preparation

[0023] 1.1.1 Culture medium and composting materials: beef extract peptone medium, improved Gao’s No. 1 medium, Martin’s medium, starch hydrolysis test, gelatin hydrolysis test, and cellulase activity determination of bacteria, fungi, and actinomycetes Medium and its counting medium [20-22] . Domestic sludge comes from Xiamen Shiweitou Sewage Treatment Plant, with 59-81% moisture, 52% total carbon (dry basis), and 1.9% total nitrogen (dry basis); Leftovers are added with appropriate amount of conditioners such as tobacco leaf residue), moisture 21-29%, total carbon 30-39% (dry basis), total nitrogen 1.1% (dry basis). The ratio of sludge and mushroom soil is 13:7 (w / w), total carbon is 41%, moisture is 60%, C / N value is 27-33, and it is used as compost raw material.

[0024] 1.1.2 Instruments and equipment: WDP microbial multi-purpose incubator, intelligent light incubator, bacteria counter, colony counter and plastic tray, etc....

Embodiment 2

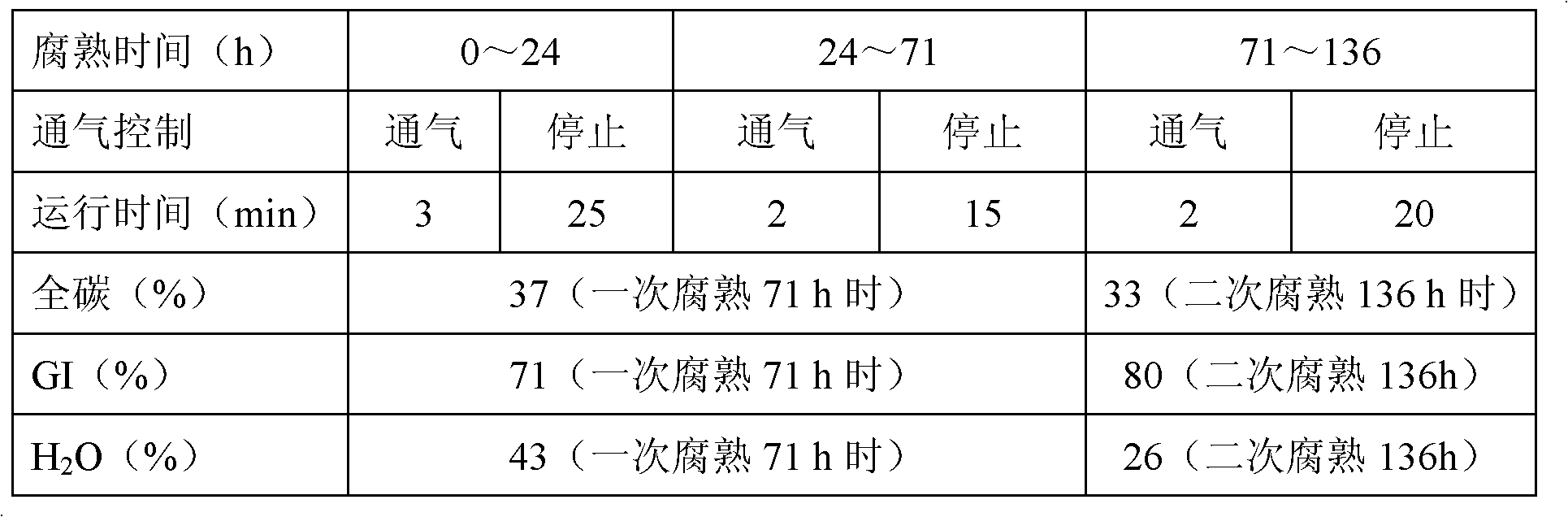

[0037] A sludge fermentation method, comprising the following steps:

[0038] A. Adjust the sludge to a water content of 55%, a total carbon ratio of 45%, and a C / N value of 27 with the leftovers of the edible fungus culture medium;

[0039] B, the first fermentation compost: add 10% (w / w) decomposing conditioner to the sludge after adjustment, its main components of this decomposing conditioner include bean cake powder 27%, starch 72%, KH 2 PO 4 1%, adjusted to 44% moisture, pH 7.1, stirred evenly, sent to the fermentation device to build a fermentation pile, heated up, and fermented for 80 hours at a fermentation temperature of 50°C and a pH value of 10.5;

[0040] C, the second fermentation compost: add 12% (w / w) decomposing conditioner to the compost after the first fermentation, its main components include soybean cake powder 20%, starch 78.8%, KH 2 PO 4 1.2%, adjusted to 50% moisture, PH 7.6, after turning and stirring,

[0041] Under the conditions of a fermentatio...

Embodiment 3

[0044] A sludge fermentation method, comprising the following steps:

[0045] A. Adjust the sludge to a water content of 65%, a total carbon ratio of 40-44%, and a C / N value of 33 with the leftovers of the edible fungus culture medium;

[0046] B. Fermentation compost for the first time: add 8% (w / w) decomposing conditioner to the sludge after adjustment, and its main components of this decomposing conditioner include bean cake powder 31%, starch 68.2%, KH 2 PO 4 0.8%, adjusted to 46% moisture, PH7.3, stirred evenly, sent to the fermentation device to build a fermentation pile, heated up, and fermented for 60 hours at a fermentation temperature of 52°C and a pH value of 8.7;

[0047] C, the second fermentation compost: add 15% (w / w) decomposing conditioner to the compost after the first fermentation, its main components include soybean cake powder 23%, starch 76%, KH 2 PO 4 1%, adjusted to 50% moisture, pH 7.6, after turning and stirring, ferment for 80 hours at a fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com