Laying hen excrement composting method capable of reducing compost raw material ammonia production amount

A composting method and technology of generating quantity, which is applied in the preparation of organic fertilizers, organic fertilizers, excrement fertilizers, etc., can solve problems such as environmental pollution and odor generation, and achieve the effects of wide sources of raw materials, promotion of compost heating, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A method for composting laying hen manure that can reduce the amount of ammonia generated by composting raw materials, comprising the following steps:

[0034] (1) Cut the straw into 2-3cm long and set aside;

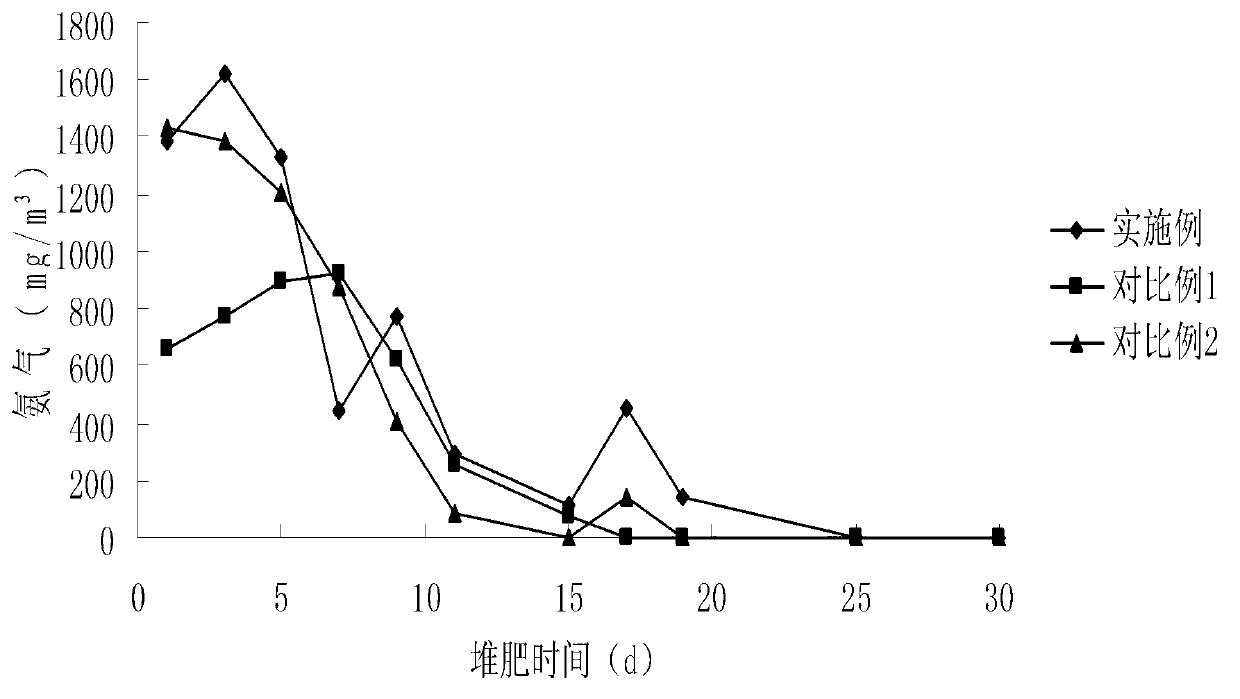

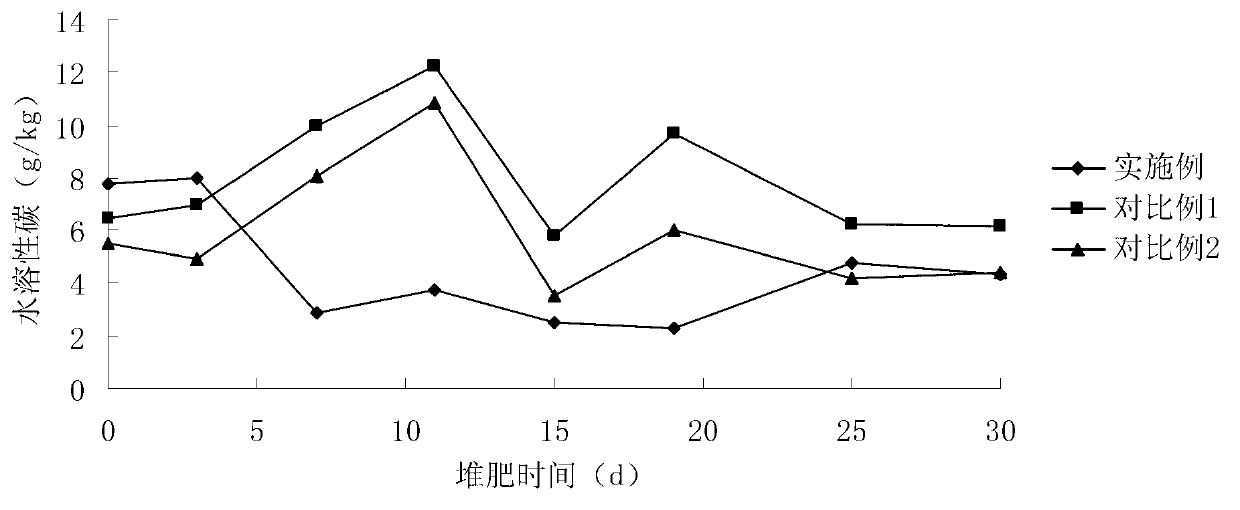

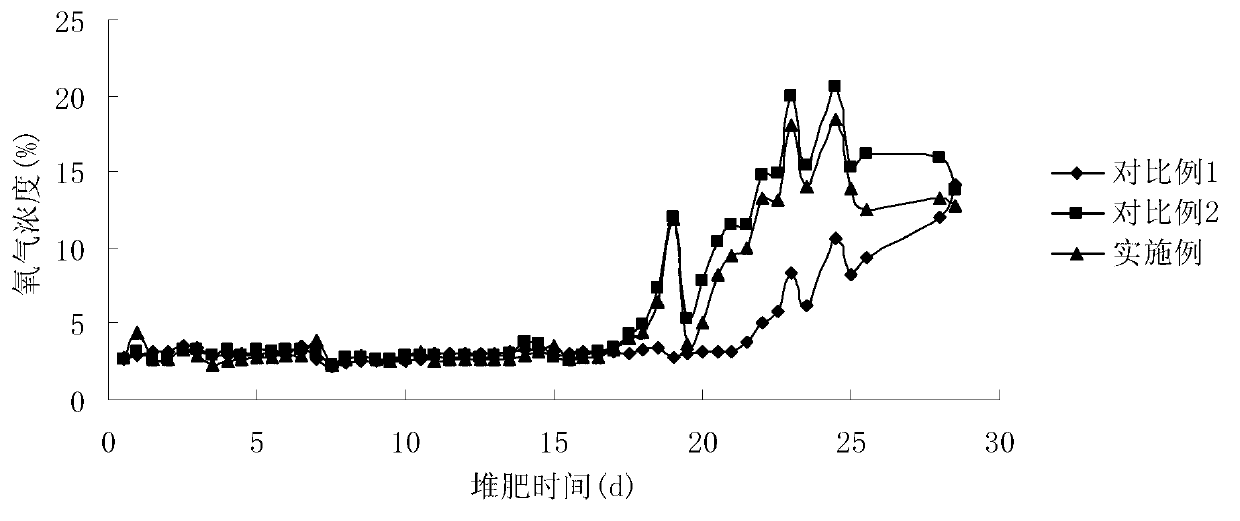

[0035] (2) Mix 224kg of laying hen manure (from laying hen manure produced by Guangdong Heyuan Dongyuan Yipin Agricultural Co., Ltd.) with 72kg of rice bran (purchased from a rice processing plant in Jinshi Village, Shuntian Town, Heyuan), and 8kg of rice straw. , the mass ratio of the three is 28:9:1, the initial C / N ratio is 13.89, the initial moisture content of the composting raw material is 60%, and the composting process is completed after 30 days of composting to obtain fertilizer; , 11, 15, 19, and 25 days to turn the pile for oxygen supply.

[0036] The compost pool used was 1.0m long, 1.0m wide, and 1.7m high. The front side was open to the outside. The compost pool was covered with a roof. When composting started, each group was covered with a plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com