Method for preparing absolute ethyl alcohol from furfural residue

An anhydrous ethanol and furfural slag technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high equipment investment cost and small device processing capacity, achieve stable product quality and improve utilization rate , the effect of a large amount of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

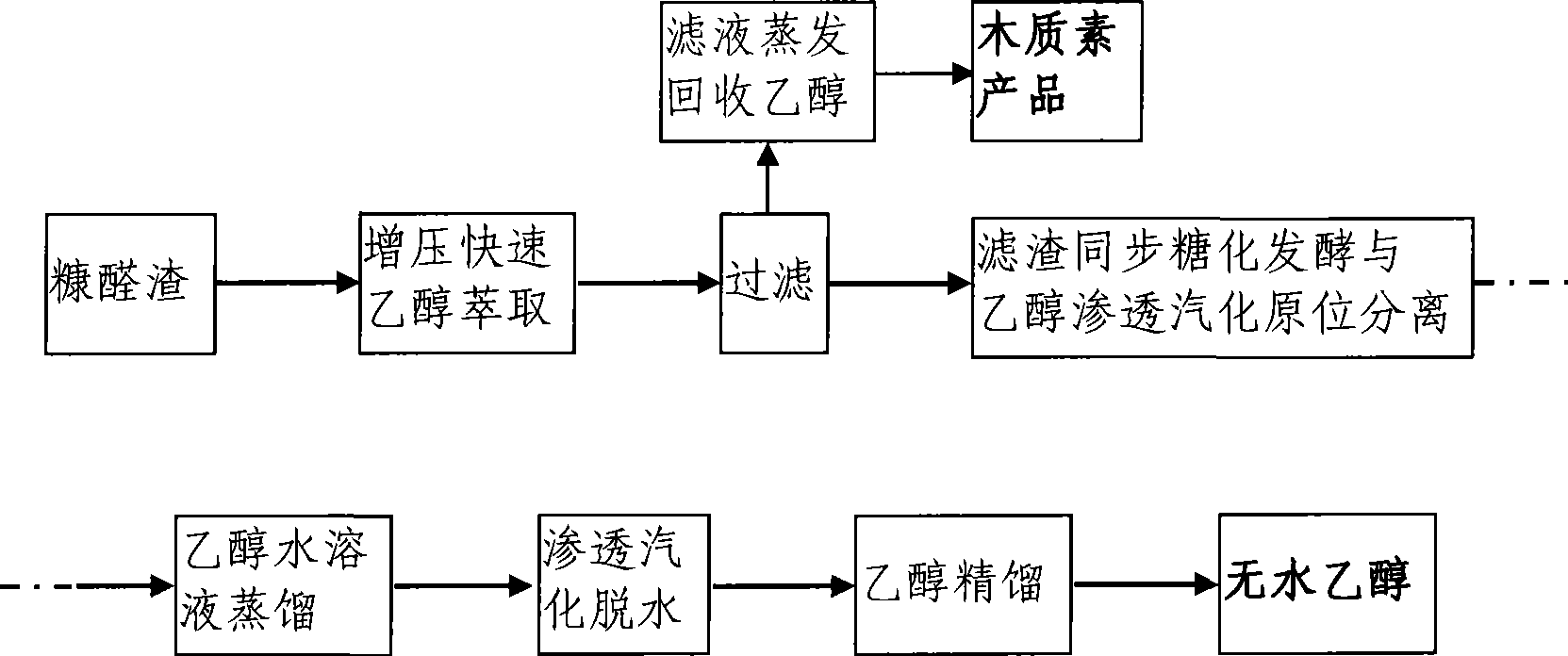

[0034] The process flow chart of preparing absolute ethanol from furfural slag in this embodiment is as follows figure 1 As shown, the specific process is as follows:

[0035] A pressurized rapid extraction method is used to extract and separate lignin from furfural residue. The mass concentration of ethanol aqueous solution of the extractant is 50%, the weight ratio of ethanol to furfural residue is 15:1, and the extraction temperature is 110°C. Pressurize for 5 minutes, pressurize at 0.6 MPa, and circulate for 1.5 hours. After the lignin extraction is completed, filter. The extract was distilled under reduced pressure, the distillate ethanol was condensed and could be recycled as an extractant, and the distillation residue was vacuum-dried at 55°C to prepare lignin with a product yield of 33.4%.

[0036] Put the sterilized extraction residue into a fermenter, and the fermenter is coupled with a pervaporation separation device. The solid-liquid ratio is 9% (w / v) during synch...

Embodiment 2

[0040] A pressurized rapid extraction method is used to extract and separate lignin from furfural residue. The mass concentration of ethanol aqueous solution of the extractant is 55%, the weight ratio of ethanol to furfural residue is 12:1, the extraction temperature is 90°C, and the pressure is increased for 10 minutes during extraction, and the increase is stopped. Press for 10 minutes, pressurize at 0.5 MPa, and circulate for 3 hours. After the lignin extraction is completed, filter. The extract was distilled under reduced pressure, and the distillate ethanol was condensed and could be recycled as an extractant, and the distillation residue was vacuum-dried at 55°C to prepare lignin with a product yield of 32.6%.

[0041] Put the sterilized extraction residue into the fermenter, the fermenter is coupled with the pervaporation separation device, the solid-liquid ratio is 10% (w / v) during the synchronous saccharification and fermentation, the dosage of cellulase is 20FPU / (g ce...

Embodiment 3

[0043] A pressurized and rapid extraction method is used to extract and separate lignin from furfural residue. The mass concentration of ethanol aqueous solution of the extractant is 60%, the weight ratio of ethanol to furfural residue is 18:1, the extraction temperature is 120°C, and the pressure is increased for 5 minutes during extraction, and the increase is stopped. Pressurize for 5 minutes, pressurize at 0.6 MPa, and circulate for 0.5 hours. After the lignin extraction is completed, filter. The extract was distilled under reduced pressure, the distillate ethanol was condensed and could be recycled as an extractant, and the distillation residue was vacuum-dried at 55°C to prepare lignin with a product yield of 34.7%. Put the sterilized extraction residue into a fermenter, and the fermenter is coupled with a pervaporation separation device. The solid-liquid ratio is 8% (w / v) during synchronous saccharification and fermentation, and the amount of cellulase is 16 FPU / (g cellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com