Preparation method of natural preservative regarding red bayberry leaves as raw material

A technology of natural preservatives and raw materials, applied in the field of food additives, can solve the problems such as the amount of sodium benzoate and the limitation of the scope of use, and achieve the effects of good sterilization and antiseptic effect, high safety in use and large amount of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

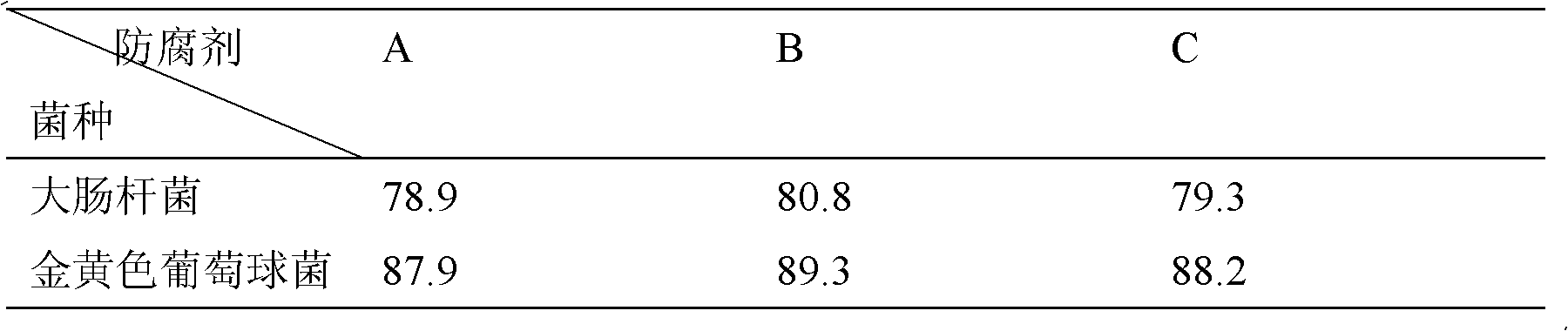

Examples

Embodiment 1

[0021] Weigh 1 part of red bayberry leaf, clean it and dry it with hot air at 50°C until the water content is 10%, crush it and pass it through a 50-mesh sieve; add 5 times the mass of ethanol with a percentage concentration of 90% to the red bayberry leaf powder, and keep the temperature at 40°C After shaking and extracting for 1.5 hours, take the filtrate, and re-extract the filter residue once according to the above steps, combine the two times of filtrate, concentrate to 0.5g of the original drug / mL, filter through a microporous membrane or centrifuge (10000r / min, 15min) and wash on the column Deseparation, the elution column is D101 type macroporous adsorption resin, the diameter and height ratio of the resin column is 1: 10, the eluent is 50%, 75% and 95% ethanol, and the elution speed is 2BV / h, each The elution time of the concentration ethanol eluent is 3h, that is, the elution volume is 6BV. The ethanol eluate is collected and then concentrated under reduced pressure ...

Embodiment 2

[0023] Weigh 1 portion of red bayberry leaf, wash it, dry it with hot air at 50°C until the moisture content is 10%, crush it and pass it through a 50-mesh sieve; add 10 times the mass of ethanol with a percentage concentration of 75% to the bayberry leaf powder, and shake at a constant temperature of 40°C After extracting for 2 hours and filtering, take the filtrate, re-extract the filter residue once according to the above steps, combine the two filtrates, concentrate to 0.8g of the original drug / mL, filter through a microporous membrane or centrifuge (10000r / min, 15min), and then apply column elution and separation , the elution column is a D101 type macroporous adsorption resin, the ratio of resin column diameter to height is 1:10, the eluent is 50%, 75% and 95% ethanol, and the elution rate is 2BV / h, each concentration of ethanol The elution time of the eluent is 3h, that is, the elution volume is 6BV. The ethanol eluate is collected and then concentrated under reduced pr...

Embodiment 3

[0025] Weigh 1 part of red bayberry leaf, clean it and dry it with hot air at 50°C until the water content is 10%, crush it and pass it through a 50-mesh sieve; add 15 times the mass of ethanol with a concentration of 60% to the red bayberry leaf powder, and keep the temperature at 40°C After shaking and extracting for 3 hours, take the filtrate, and re-extract the filter residue once according to the above steps, combine the two filtrates, concentrate to 1g of the original drug / mL, filter through a microporous membrane or centrifuge (10000r / min, 15min), and then apply column elution and separation , the elution column is a D101 type macroporous adsorption resin, the ratio of resin column diameter to height is 1:10, the eluent is 50%, 75% and 95% ethanol, and the elution rate is 2BV / h, each concentration of ethanol The elution time of the eluent is 3h, that is, the elution volume is 6BV. The ethanol eluate is collected and then concentrated under reduced pressure to obtain a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com