Method for comprehensively utilizing laterite-type nickel ore

A technology of laterite-type nickel ore and nickel ore, applied in the direction of improving process efficiency, can solve the problems of low production cost, low recovery rate, high energy consumption, etc., and achieve the effects of improving nickel grade, easy operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

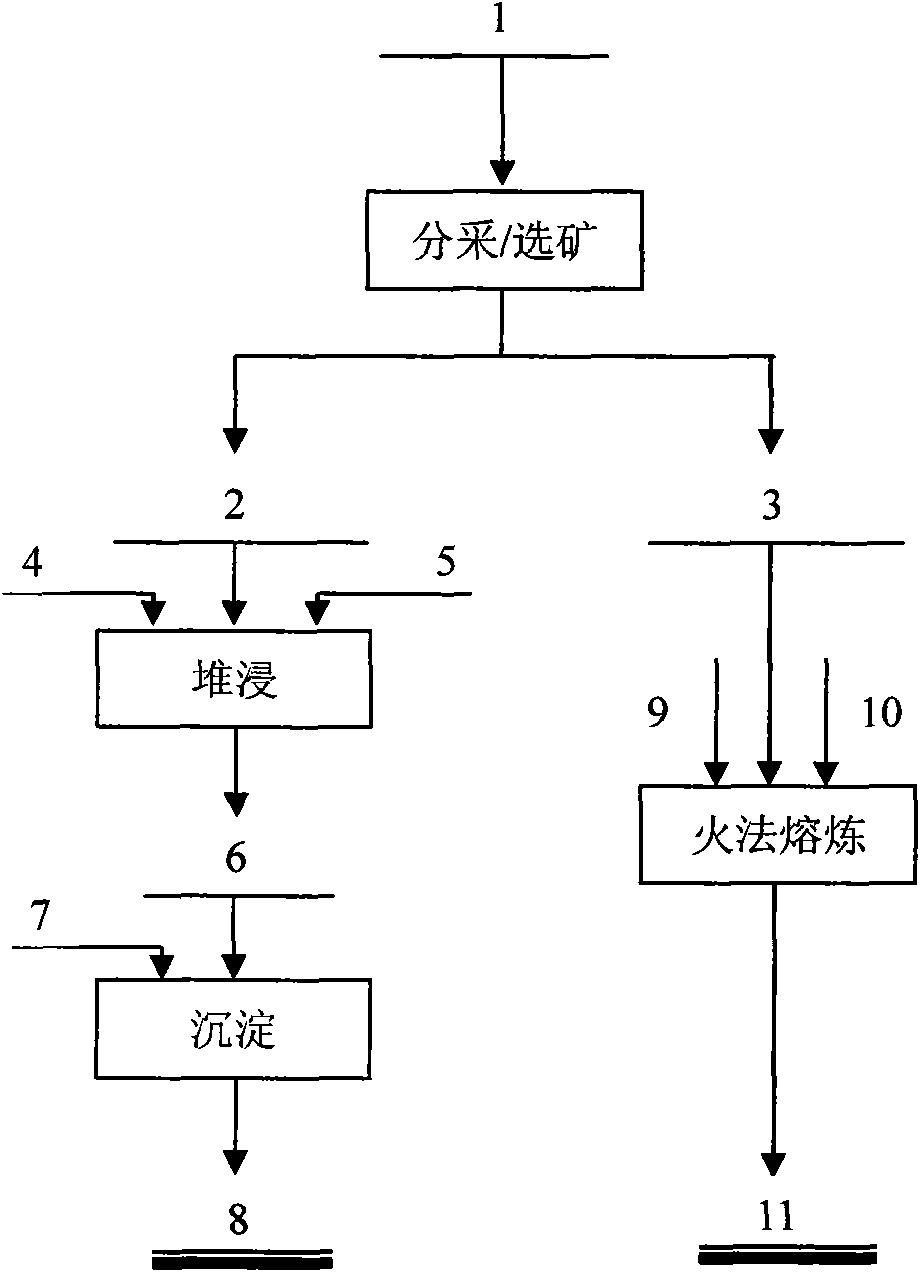

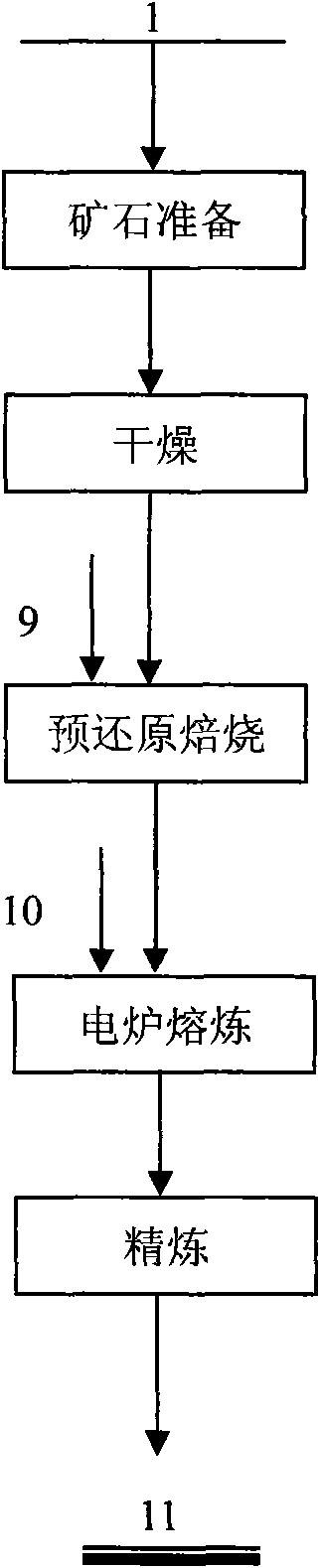

Method used

Image

Examples

Embodiment and

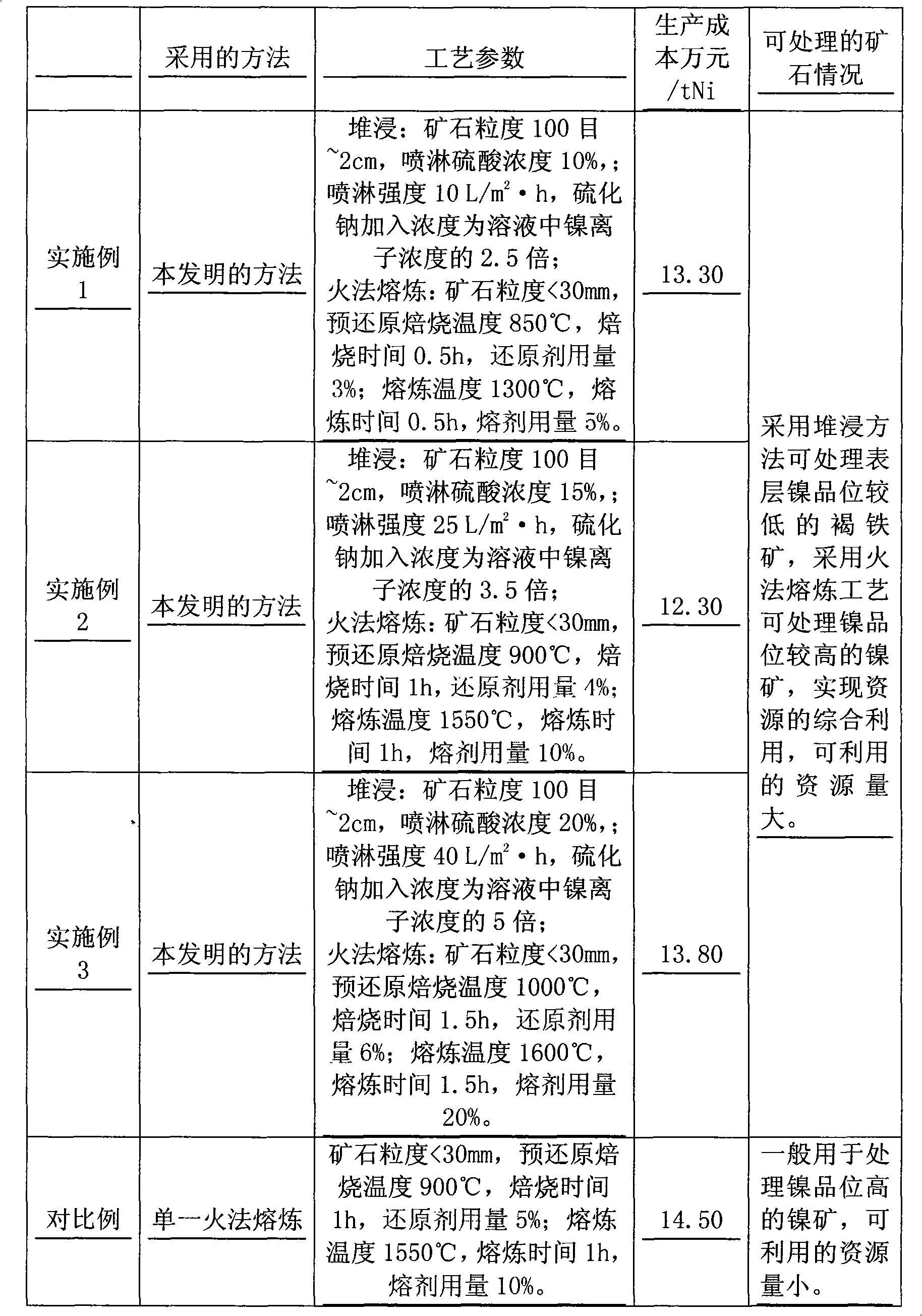

[0035] Table 1 Embodiment of the present invention and single pyromelting comparative example

[0036]

[0037] As can be seen from Table 1, the production cost of nickel is calculated according to the price of my country in 2008. The average production cost of the three embodiments of the inventive method is 131,300 yuan / tNi, and the amount of available resources is large. smelting method, the production cost is 145,000 yuan / tNi, and the amount of available resources is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com